You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Falcon 170 Fuel Pump

- Thread starter Seattle63

- Start date

I replaced the fuel pump and was too high on pressure. Bought another Carter and summit sent wrong pump. Is the canister filter on top or bottom. The lever connector to cam right make contact on top or bottom. Can I post a photo on this site?

Seattle63, welcome aboard.

Members are experiencing high failure rate with today’s aftermarket fuel pumps. Some members are going to electric fuel pump because they were having multiple failures with new mechanical fuel pumps. Try another fuel pump and see what happens. If you’re still having problems, we can discuss other options. Some options are relatively cheap and simple to install.

Added:

If you need the car to look period correct under the hood. There are ways to make that happen fairly easily with an electric fuel pump near the fuel tank and modifying the mechanical pump. Keep your original fuel pump just in case.

Members are experiencing high failure rate with today’s aftermarket fuel pumps. Some members are going to electric fuel pump because they were having multiple failures with new mechanical fuel pumps. Try another fuel pump and see what happens. If you’re still having problems, we can discuss other options. Some options are relatively cheap and simple to install.

Added:

If you need the car to look period correct under the hood. There are ways to make that happen fairly easily with an electric fuel pump near the fuel tank and modifying the mechanical pump. Keep your original fuel pump just in case.

Last edited:

You’re welcome,

I ask some members to try a Cube pump made by Facet. One of the members here reported back and said it’s been working very well.

Below is a model that should work well for your application:

www.pegasusautoracing.com

The fuel pump linked above is used in quite a few industrial applications. It’s as simple as it will get.

www.pegasusautoracing.com

The fuel pump linked above is used in quite a few industrial applications. It’s as simple as it will get.

Added:

Here is a mounting kit that is available. It should help suppress pump noise.

www.pegasusautoracing.com

www.pegasusautoracing.com

I ask some members to try a Cube pump made by Facet. One of the members here reported back and said it’s been working very well.

Below is a model that should work well for your application:

Facet Cube 12v Fuel Pump Kit, 1/8 NPT, 4 to 7 psi - Pegasus Auto Racing Supplies

This Facet Cube 12V Fuel Pump Kit is for moderate fuel requirements of carbureted engines up to about 150 horsepower. Kit contains pump, mounting hardware, filter and adapter to accept 5/16" fuel hose.

Added:

Here is a mounting kit that is available. It should help suppress pump noise.

Facet Heavy Duty Mounting Kit for Fuel Pumps - Pegasus Auto Racing Supplies

Our Heavy Duty Fuel Pump Mounting Kit isolates your electric pump for quieter operation and allows the use of negative-ground pumps on positive-ground vehicles.

Last edited:

Saettle63, welcome!

I'm one of those who is using this brand pump, from 63Sprint's lead. It is not the one he listed above. I got the same pump but with the 3/8" inlet/outlet, not the 1/8".

It has been in service in a F100 pickup for about 7 months, flawless so far. Stable fuel pressure and also cooler fuel are benefits of going electric. Oh, and priming the carb after an extended off-period, a significant plus as well. Truck can sit for weeks, fires off instantly since fuel is already supplied to the carb.

It's installed on the frame near the tank with the isolator kit posted above, barely audible with engine off.

www.pegasusautoracing.com

www.pegasusautoracing.com

I'm one of those who is using this brand pump, from 63Sprint's lead. It is not the one he listed above. I got the same pump but with the 3/8" inlet/outlet, not the 1/8".

It has been in service in a F100 pickup for about 7 months, flawless so far. Stable fuel pressure and also cooler fuel are benefits of going electric. Oh, and priming the carb after an extended off-period, a significant plus as well. Truck can sit for weeks, fires off instantly since fuel is already supplied to the carb.

It's installed on the frame near the tank with the isolator kit posted above, barely audible with engine off.

Facet Cube 12v Fuel Pump, 3/8 NPT, 4-7 psi | Pegasus Auto Racing Supplies

The Facet 40109 Cube 12 Volt Fuel Pump delivers a maximum flow of 32 GPH or 4-7 psi max pressure. Has large 3/8 NPT female ports.

Frank, glad the pump is doing well. I’ve seen them run thousands of hours on industrial equipment without any failures.

About inlet and outlet size difference.

The pump your using, and the one I listed on post #6 have the exact flow rate. The benefits of the 1/8” NPT inlet and outlet is, the fittings are the exact size for 5/16” fuel lines. This makes a much simpler installation. The flow restriction is not at the 1/8” NPT fittings on the pump. It’s at the needle seat in the carburetor.

If I took my time and went through all the models listed carefully earlier, I probably would have talked to you about the one I just listed. Both pumps are good, again, they both have the same flow rate.

The benefit of the FAC-FEP289SV Pump kit is, its complete. And its price is cheaper than just a pump and it would be a clean, simple install.

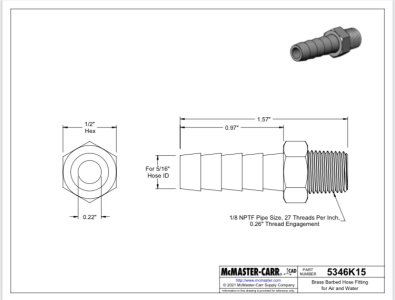

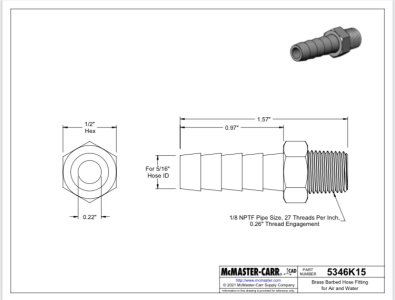

Here is a 2D CAD drawing of the barbed adaptor. The through hole is 0.22”. It’s plenty.

A similar fuel filter that comes in the FAC-FEP289SV Pump kit is used on numerous Ford vehicles. Here’s a few listed below:

• 1974 Ford F250, 390 FE 2 barrel.

• 1974 Ford Torino, 351 Windsor 2 barrel.

• 1974 Ford F250, 300 1barrel.

• 1974 Ford Maverick, 200 1 barrel.

About inlet and outlet size difference.

The pump your using, and the one I listed on post #6 have the exact flow rate. The benefits of the 1/8” NPT inlet and outlet is, the fittings are the exact size for 5/16” fuel lines. This makes a much simpler installation. The flow restriction is not at the 1/8” NPT fittings on the pump. It’s at the needle seat in the carburetor.

If I took my time and went through all the models listed carefully earlier, I probably would have talked to you about the one I just listed. Both pumps are good, again, they both have the same flow rate.

The benefit of the FAC-FEP289SV Pump kit is, its complete. And its price is cheaper than just a pump and it would be a clean, simple install.

Here is a 2D CAD drawing of the barbed adaptor. The through hole is 0.22”. It’s plenty.

A similar fuel filter that comes in the FAC-FEP289SV Pump kit is used on numerous Ford vehicles. Here’s a few listed below:

• 1974 Ford F250, 390 FE 2 barrel.

• 1974 Ford Torino, 351 Windsor 2 barrel.

• 1974 Ford F250, 300 1barrel.

• 1974 Ford Maverick, 200 1 barrel.

Last edited:

You can use any power on/off method you choose. I prefer having an on/off dash toggle switch that is live when the ignition is on. 3 reasons- 1) can pre-prime the carb after the vehicle has sat for more than a few days. This eliminates extra cranking time to move fuel into the carb. 2) the pump can be turned off 5-30 seconds before the engine is shut off. This eliminates pressure at the carb, especially helpful to avoid hot-soak restart issues. The Pegasus pump has a check valve. Any pressure left in the line remains pressurized after engine is off. 3) A good anti-theft device. Even if someone gets the vehicle hot wired and drives off, once the carb goes dry they're quickly done if the pump toggle is off.Do I have to use an oil pressure gauge switch. Or can I use a two lead switch?

I recommend good gauge wire, and a solid power source, fused. My pump operates off a relay which powers the ignition system and pump directly from the battery. . Also I did not ground the pump at the frame with the wire supplied. Over time corrosion builds up under there, I ran a second wire, grounding the pump with the engine-to-frame ground lug on the firewall.

Last edited:

You can use any power on/off method you choose. I prefer having an on/off dash toggle switch that is live when the ignition is on. 3 reasons- 1) can pre-prime the carb after the vehicle has sat for more than a few days. This eliminates extra cranking time to move fuel into the carb. 2) the pump can be turned off 5-30 seconds before the engine is shut off. This eliminates pressure at the carb, especially helpful to avoid hot-soak restart issues. The Pegasus pump has a check valve. Any pressure left in the line remains pressurized after engine is off. 3) A good anti-theft device. Even if someone gets the vehicle hot wired and drives off, once the carb goes dry they're quickly done if the pump toggle is off.

I recommend good gauge wire, and a solid power source, fused. My pump operates off a relay which powers the ignition system and pump directly from the battery. . Also I did not ground the pump at the frame with the wire supplied. Over time corrosion builds up under there, I ran a second wire, grounding the pump with the engine-to-frame ground lug on the firewall.

Thanks Good info

It would be best to install an inertia switch while you’re at it. The thought of the fuel pump not turning off if you’re ever in an accident and become unconscious just does not sit well.

Better yet:

www.summitracing.com

www.summitracing.com

Better yet:

Painless Performance 80160 Painless Performance Rollover Safety Switches | Summit Racing

Free Shipping - Painless Performance Rollover Safety Switches with qualifying orders of $109. Shop Electrical Switches at Summit Racing.

Last edited:

I cant second this comment enuff. Reason Y I dont use the ele - fires.

Glad some 1 else did as I feared entering it yet again. Unconscious can be

more than a knock on the head. Getting in a bump-up creates absent mindedness.

Will U think of the switch, no you’ll B cursing the other driver, situation, or taking care of

other things, not thinking “Oh, yeah, let me flip the lill switch."

/OR/

as most do - there is no switch...

thnx spint

Glad some 1 else did as I feared entering it yet again. Unconscious can be

more than a knock on the head. Getting in a bump-up creates absent mindedness.

Will U think of the switch, no you’ll B cursing the other driver, situation, or taking care of

other things, not thinking “Oh, yeah, let me flip the lill switch."

/OR/

as most do - there is no switch...

thnx spint

borg warner goes chinese :

Auburn Hills, Michigan, October 2, 2020 – BorgWarner Inc. (NYSE: BWA) today announced it has completed its acquisition of Delphi Technologies. The combination of BorgWarner and Delphi Technologies is expected to strengthen BorgWarner’s electronics and power electronics products, capabilities and scale, creating a leader in electrified propulsion systems that BorgWarner believes is well-positioned to take advantage of future propulsion migration.

"We are pleased to complete our acquisition of Delphi Technologies,” said Frédéric Lissalde, President and CEO, BorgWarner. “Through this combination, BorgWarner is even better positioned with a more comprehensive portfolio of industry-leading electric propulsion products and systems across combustion, hybrid and electric vehicles.

Auburn Hills, Michigan, October 2, 2020 – BorgWarner Inc. (NYSE: BWA) today announced it has completed its acquisition of Delphi Technologies. The combination of BorgWarner and Delphi Technologies is expected to strengthen BorgWarner’s electronics and power electronics products, capabilities and scale, creating a leader in electrified propulsion systems that BorgWarner believes is well-positioned to take advantage of future propulsion migration.

"We are pleased to complete our acquisition of Delphi Technologies,” said Frédéric Lissalde, President and CEO, BorgWarner. “Through this combination, BorgWarner is even better positioned with a more comprehensive portfolio of industry-leading electric propulsion products and systems across combustion, hybrid and electric vehicles.

Last edited:

https://www.lmctruck.com/fuel-system/fuel-pumps/fbr-1966-77-fuel-pumpsI replaced the fuel pump and was too high on pressure. Bought another Carter and summit sent wrong pump. Is the canister filter on top or bottom. The lever connector to cam right make contact on top or bottom. Can I post a photo on this site?

43-4721 is f/p 4a vac wiper app. on lmc truck cat. ...

An on/off switch is no good in my mind. If

ina accedent I’m not thinkin “now did I / I need to... shut off that switch". I’m thinking

EVERYTHING else

“Y dat bastard”, “Every body OK?”; “am I ok?”; "will insurance cover?”; better get oudda da rd or more troubles acomin” etc

Inertia switch is ina vehicle 4a reason...

An on/off switch is no good in my mind. If

ina accedent I’m not thinkin “now did I / I need to... shut off that switch". I’m thinking

EVERYTHING else

“Y dat bastard”, “Every body OK?”; “am I ok?”; "will insurance cover?”; better get oudda da rd or more troubles acomin” etc

Inertia switch is ina vehicle 4a reason...

from previous post:

( For safety, electric pump systems should incorporate at least an oil pressure switched power source ( with ign,/start bypass) in case of a fault/leak in fuel supply. Factory setups typically also include a rollover valve for worst case scenarios ...)

https://www.summitracing.com/search?Sor ... y%20switch

( oil pressure port tapped for Fuel Pump safety oil pressure I ign bypass switch, SC oil line feed, original idiot lamp switch and NHRA compliant metallic cabin mechanical oil pressure gauge line.)

.

.

.

BTW - when cranking with the elec pump and oil pressure cut-off switch, once oil pressure reaches @ 5 lbs, the pump keeps priming until oil pressure drops way down again effectively priming carb.

.

.

have fun

( For safety, electric pump systems should incorporate at least an oil pressure switched power source ( with ign,/start bypass) in case of a fault/leak in fuel supply. Factory setups typically also include a rollover valve for worst case scenarios ...)

https://www.summitracing.com/search?Sor ... y%20switch

( oil pressure port tapped for Fuel Pump safety oil pressure I ign bypass switch, SC oil line feed, original idiot lamp switch and NHRA compliant metallic cabin mechanical oil pressure gauge line.)

.

.

.

BTW - when cranking with the elec pump and oil pressure cut-off switch, once oil pressure reaches @ 5 lbs, the pump keeps priming until oil pressure drops way down again effectively priming carb.

.

.

have fun

interested, show schematics, plez.

Auto electrics = my worse abilities.

What currently made (or last few yrs)

have this 'oil pressure switch' incorporated

into their oem fuel applications? I dont believe I've

seen this. May B never hada trouble shoot them - a

good sign, no? LOL

Auto electrics = my worse abilities.

What currently made (or last few yrs)

have this 'oil pressure switch' incorporated

into their oem fuel applications? I dont believe I've

seen this. May B never hada trouble shoot them - a

good sign, no? LOL

Similar threads

- Replies

- 11

- Views

- 468

- Replies

- 5

- Views

- 943

- Replies

- 1

- Views

- 112

- Replies

- 1

- Views

- 1K