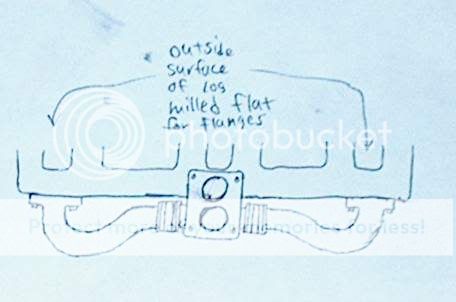

It's lovely. You've given birth to a Tunnel Ram i6 intake, Powerband. Just add another two 500 cfm carbs!

From

viewtopic.php?f=5&t=31668

I found I could run the time honoured Weber Isolated runner details

http://img.photobucket.com/albums/v223/ ... ing_II.jpg

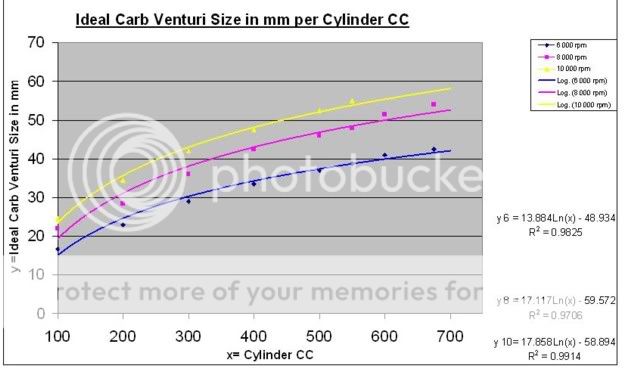

I'd done some rearranging to this. It produces the carb size in mm's via the LN function at 6, 8 and 10 000 rpm, so its out of range for the 3500 to 5000 rpm our stock sixes often do.

Back then, I was thinking only three 350or 500 cfm carbs, but you can do it with a mixture of 4-bbl and 2 bbl carbs. It would then becoem a tunnel ram intake!

Summary of my purpose then was .

1. I'm trying to bring Port on port, isolated runner 'pulse tuning' right down to our stock 252 , 256 and 264 cams used in 200 and 250 I6 Fords, and fill out the torque power and economy curves as much as possible with stock Holley 2300 series 350 or 500 cfm parts.

2. I'm defining ideal Holley carb sizes by use on existing 200 and 250 engines, and defining new so-called Y3.5, Y4 and Y4.5 values for 3500, 4000 and 4500 rpm based on the time honoured Weber Isolated runner venturi chart

Background absolutes.

1. The ideal engine capacity for 2300 series 350 and 500 cfm, or split 4500 1050 or 1150 Holleys on I6 engines is a natural log (Ln) function. The Ln function varies due to rpm at maximum power.

As listed above, the venturi sizes in mm's are listed

at Y6 (6 000 rpm) is 13.9 Ln(x)-48.9,

at Y8 (8 000 rpm) is 17.1 Ln(x)-59.6

and Y10 (10 000 rpm) is 17.9 Ln(x)-58.9

From

http://forums.hybridz.org/showthread.php?p=680623, I followed a link, and found the formulae for 5000 rpm via use of a Weber Jetting program used for 1200 to 2400 cc 4-cyl engines. It confirms the Y6 and Y8 equations. For Y5, the formula is

Y5, (5000 rpm) is 12.5 Ln(x)-46.8

The carb tuning looks to be so sensitive that a venturi even a mm or 40 thou too big or too small can vary the power rpm by 200 rpm.

I'm aiming for a Y4 (4000 rpm) or even Y3.5 (3500rpm) target.

I am now summarizing that a 250 Falcon with a three #4412 500 carbs needs a cam which provides peak power at 5000 rpm.

A 200 Falcon six with three #7448 or 9117 350 cfm carbs needs a cam whch provides power at below 5000 rpm, possibly 4800 rpm.

A 250 Falcon six with three #7448 or 9117 350 cfm carbs should only need a cam which provides power to 3500 rpm to run in an optimized manner.

2. Since I have an engine block that can be built as a 200, 221, or 250, and a block which can take any Ford head, and any number of cams, I can test any engine configuration.

3. The time hounoured standard jetting of isolated runner engines with no power valve, is always 1/25 th of the venturi diameter. So a 350 will like a 48 jet, a 500 will like a 56 jet. Since one carb is working for only a third of an engine , a power valve may need to be two stage and the PVCR's have to be reduced from 53 or 62 thou down to perhaps 16 to 19 thou. Any of the commonly available two stage power valves will cover for the difference from open loop (11.5:1 , wide open throttle ) to close loop (14.7:1, cruise) conditions. This will allow an effective enrichment of 2 or 3 jet sizes whenever vaccum drops, but will do so in stages. With some science applied, a triple carb engine should lean cruise like an EFI champion.