Rmoore45

Well-known member

Didn't see a specific area to ask questions about tools so this'll have to do.

Looking for recommendations regarding a micrometer and dial bore gauge for measuring main and rod bearing clearances. As well as any other precision tools that I'll need to assemble an engine. Looking for high quality tools, they will be an investment for future projects so price isn't a big factor.

Tools I currently have

Been looking at Starrett tools but I'm no expert on the subject and there are many different options out there.

Thanks

Looking for recommendations regarding a micrometer and dial bore gauge for measuring main and rod bearing clearances. As well as any other precision tools that I'll need to assemble an engine. Looking for high quality tools, they will be an investment for future projects so price isn't a big factor.

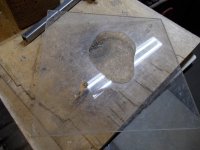

Tools I currently have

- Basic Hand Tools

- Torque Wrenches

- 0-6" Digital Caliper

- Cam Bearing Removal & Installation Tool

- Dial Indicator with magnetic stand (bought for doing differential rebuilds)

Been looking at Starrett tools but I'm no expert on the subject and there are many different options out there.

Thanks