You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

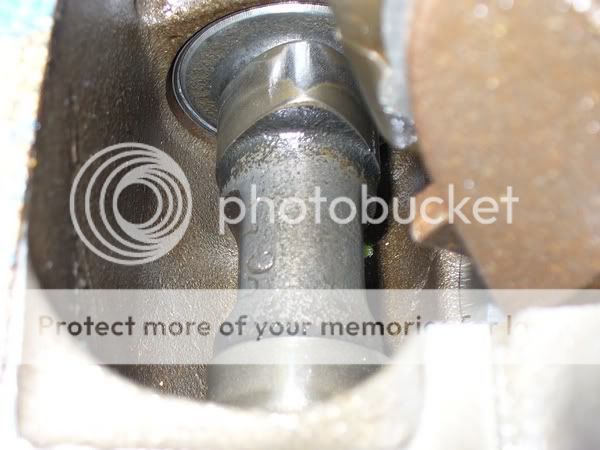

Rod hits camshaft

- Thread starter JackFish

- Start date

You might have go back to straight up or a little less advance.

:wow: x2Frankenstang":mojfkbyh said::wow:JackFish":mojfkbyh said:

I'd say that particular aftermarket cam and with that later 1978 rod have less clearance than the stock 6250 cast Ford camshaft used in 200 applications. The FSSP core is specially made, and I think there were some changes to it if I recall. Mike did field some questions because the big cam, crank rod spacing on 250 didn't have the space issue like the little 200.

Politely chat to Az (Mike) and it may be an exceptable option for the cam to linished to create clearance at worst case. Often, rods can be clearanced more cheaply than maching a camshaft.

Although not related to the cam, clearance issues used to happen with Aussie Ford 221 cranks into 186 Holdens, and all they did was ground the rod and cam to gain more than 60 thou clearance at full revs. When the counterweighted seven bearing 200 crank came in 1965, the crank hit the earlier oil pump designed for the four bearing 1964 200 engine.

Ford made a lot of running changes on 200's 1963 to 1965. The cam to crank spacing was actually optimized for a 2.4" stroke 144, not the later 2.94 and 3.126" of the 170 and 200. As a result, some of those earlier 144/170 or four bearing cams don't fit US 200 blocks with forged rods. There was also a crank casting change and rod change with the 1978 Fox engines which might have made things a little bit difficult when the cam is advanced or retarded.

Politely chat to Az (Mike) and it may be an exceptable option for the cam to linished to create clearance at worst case. Often, rods can be clearanced more cheaply than maching a camshaft.

Although not related to the cam, clearance issues used to happen with Aussie Ford 221 cranks into 186 Holdens, and all they did was ground the rod and cam to gain more than 60 thou clearance at full revs. When the counterweighted seven bearing 200 crank came in 1965, the crank hit the earlier oil pump designed for the four bearing 1964 200 engine.

Ford made a lot of running changes on 200's 1963 to 1965. The cam to crank spacing was actually optimized for a 2.4" stroke 144, not the later 2.94 and 3.126" of the 170 and 200. As a result, some of those earlier 144/170 or four bearing cams don't fit US 200 blocks with forged rods. There was also a crank casting change and rod change with the 1978 Fox engines which might have made things a little bit difficult when the cam is advanced or retarded.

Thanks everyone for your comments and insights.

The options I am considering at the moment are;

1. take the cam out while it's now readily accessible and take it to a grinder here that can correct the issue.

2. leave it straight up or installed 1 or 2 degrees advanced, which might at least help compensate for chain stretch over time.

3. take a file to it and bubba the cam.

I think I will try to get a caliper in there and measure some things today.

It's odd that it happens only on the two center cylinders, with #4 being worse that #3.

I would not be surprised if this cam was some "old stock" as I bought it in '05, and it could have been sitting on a shelf for a while before then.

The options I am considering at the moment are;

1. take the cam out while it's now readily accessible and take it to a grinder here that can correct the issue.

2. leave it straight up or installed 1 or 2 degrees advanced, which might at least help compensate for chain stretch over time.

3. take a file to it and bubba the cam.

I think I will try to get a caliper in there and measure some things today.

It's odd that it happens only on the two center cylinders, with #4 being worse that #3.

I would not be surprised if this cam was some "old stock" as I bought it in '05, and it could have been sitting on a shelf for a while before then.

I have never degreed a smal ford six or the timming set in question. However, I would like to say that I have degreed many cams and have almost never found a timing set to be correct on the alternate keys. Most SBC sets come out to double. If you change it to the 4 degree marks, it will be 8 degrees when checked with a degree wheel. I would never change one without putting a wheel on it.

Having clearenced literaly hundreds of SBC robs for 383's, I would be inclined to look to the rod for clearence. If it can be done without getting too far into the bolt.

Having clearenced literaly hundreds of SBC robs for 383's, I would be inclined to look to the rod for clearence. If it can be done without getting too far into the bolt.

Gary, on the sbc if the change is on the camshaft gear it is double.

On the six the change is on the crankshaft & 2 degrees is 2 degrees for all the 200 ford sixes.

On a cloyes set for the sbc the change is on the crank gear. The old bushings on the cam gear were definitely like you said double.

As you stated redegree to be on the safe side.

I think in Jacks deal i would take it off the camshaft, cause the spring tension is probably under 100# & that camshaft does not have a fast opening rate.

If you were running a cam with .560" lift & 135# seat pressure & 340# open then i would take it off the rod.

JUST don't grind more than you need. Bill

On the six the change is on the crankshaft & 2 degrees is 2 degrees for all the 200 ford sixes.

On a cloyes set for the sbc the change is on the crank gear. The old bushings on the cam gear were definitely like you said double.

As you stated redegree to be on the safe side.

I think in Jacks deal i would take it off the camshaft, cause the spring tension is probably under 100# & that camshaft does not have a fast opening rate.

If you were running a cam with .560" lift & 135# seat pressure & 340# open then i would take it off the rod.

JUST don't grind more than you need. Bill

That is quite a differance. The CS cam has a casting number there in the pic dose the stocker shaft have the same number?

Jack, I hope u didn't jix anyone... I didn't degree my cam I had the shop that built my engine do it for me. Mike's Head builder called him with some news thinking due to the layer off gunk in the valve bowls in my head that my cam might be 'retarded' I'll be degree'n it here soon and I'll post my findings, fingers crossed I don't find myself in the same situation as you're going through. Good Luck, I really appreciate this post on your findings.JackFish":1kw1tgwb said:This is a serious engineering flaw.

It's strange because I have not seen any other reports here of similar problems.

Am I the only one to have received a bad shaft from Classic Inlines?

I wouldn't be surprised, I know people in the industry, and sometimes you can put a camshaft in the grinder off index. Maybe QA missed one. Usually this kind of business isn't automated, which means just because one cam is off doesn't mean the rest are, especially if a guy is switching runs or new to a line and is used to grinding a cam with more innate advance. I'd talk to Mike and compare photo's of your cam to others he has in stock, see if they deviate or match. Comparing an aftermarket cam to a stock cam isn't a good comparison. I bought what I think is the same cam from another forum member, should be here next week (~19th) and I'd be happy to swap snappies with you for a compare. Mike might be quicker though.

There were about two shaft design (blanks or cores used) Cams are ground indexed to 1969 and earlier engines. Later Cams (cores) are indexed for use in 1970 and later engines. These can be used in earlier engines too but they must be carefully degreed in.

Jackfish, what year rods are you using?? Sounds like the cast rods are beefier in the big end if thats what you are using.

I would grind the camshaft & be done with it.

I have confidence in your degreeing so remove the shaft & grind where needed. Bill

I would grind the camshaft & be done with it.

I have confidence in your degreeing so remove the shaft & grind where needed. Bill

I agree with wsaIII, since you confirmed the timing events with a degree wheel, I would advance it back where you wanted it to start with and removed the material from the camshaft. It isn't necessary to break all 6 rods apart and risk junk getting in the bearings. Also, keep in mind that these cam blanks are cast and not a machined part as far as the notch goes and is subject to variation from time to time, just like a block or head casting, and might not mean that there is really anything wrong.

I've decided on running it as is.

I don't really have the time, money or the inclination to fool around with this right now.

I was able to advance the cam 1 degree with confidence so I I left it at that and buttoned it up.

At some point down the road the engine will be coming out again and I will deal with it then, or not.

It's disappointing at the very least.

Kind of makes me want to build a V8 just due to the plethora of parts and vendor options.

I don't really have the time, money or the inclination to fool around with this right now.

I was able to advance the cam 1 degree with confidence so I I left it at that and buttoned it up.

At some point down the road the engine will be coming out again and I will deal with it then, or not.

It's disappointing at the very least.

Kind of makes me want to build a V8 just due to the plethora of parts and vendor options.