Don't argue with drag racers, they

know.

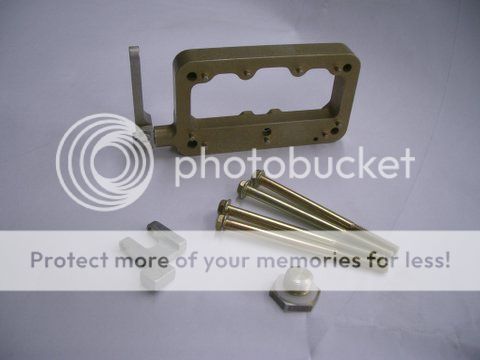

I had to blow these dang low pixle images the heck up to see a proper carb entry.

viewtopic.php?f=40&t=41798&p=502631#p502631

I expected with your Classic Inlines combo and your engine settings about that carb about 165 rear wheel hp easily.

If you were able to drag race it now, I'd be certain from those dyno figures that you'd have a result for mph which indicates 140 rear wheel hp, but that may require 195 to 228 hp to get 140 rear wheel hp. A lot more hp gets lost with even a stout rebuild converter and good shift kit.

viewtopic.php?f=1&t=69807

Three parts to this story.

Point 1, A pure drag racing auto shows often a 15% loss off the engine dyno with an auto because planetary gear sets and converters are the ideal launch for cars in the 20 to 10 second quarter bracket. But on a chassis dyno to drag racing end of quarter mile mph test, it won't show 15% if it has a torque converter. It'll be a nominal 40 to 60 hp, with my observed 39 to 63 % based on 50 years of Ford Six and V8 data with automatics and stick shifts. The info from a host of magazines who have tested this backs it up, it is irrefutable.

Point 2. For anything else, I'll use evidence and be a self quotin' pompass a$$ on the side of educating the dyno going population. Yeah!

Figures don't lie, any chassis dyno test is just a back to back comparo on the best combo of the day. So is drag racing a car over the standing eighth or quarter mile. I know that 39 to 63% is the likely loss over the flywheel to rear bags on a dyno, so You'll have 195 to perhaps 228 flywheel hp if a torque converter is involved and if that 140 hp at the bags is on a calibrated dyno. I can absolutely assure you of that. More to the point, 182 lb-ft is 255 to 297 lb-ft of torque, 302 or stock to mild 351 territory.

Point 3.

Read How to Modify Ford SOHC Engines David Vizard pages listed in the index from 63 on Carbs.

http://www.scribd.com/doc/26804743/How- ... vid-Vizard

Look at how the best racers manage fuel stand off....look at FSD's old 250 Tri power Mustang engine combo photo's to see how he gets air flow.

You need this

Three Quarter Inch David Vizard Five Point Eight Percent Flow increase Carb Bell Mouth

On 250's, Traditionally, fuel standoff (the fuel haze with the hood up and no air cleaner, the top of the roosters tail of atomized fuel flow into the engine) needs to be fully contained all the way through the rev range by trying to raise and widen the area around and above the carb air horn. Its classic engineering flow net stuff. In practice, David Vizard found that you can run a flat plate close to a carb air horn if the annular zone around the carb is maximized.

The engine is 1.666 " taller than the 200, so height is limited with respect to hood clearance, so you have to go wide and allow the air to turn in.

I'm a total advocate with our tall I6's of doing a full Autolite, Holley or Motorcraft air horn removal, and then find a method of richening up the mixture for a cold start that isn't a conventional choke. By putting a throttle lean out device or adjusta jet or some tojer means, you can then make a wide base air cleaner like the old 2V Falcon 170 hp M codes ran. The only had just over one inch of air cleaner, but they had over 10 inches of wide brimmed hat air cleaner to pull in air.

That's what makes hp.

The reason the carb hat is loosing you power is that cam profile needs space for air fuel containment. You can't go up for height, so you gotta go wide.

Refer this for ideal containment profiles. Holden guys in Aussie have been studying it for years

http://forum.fefcholden.club/index.php?topic=23061.100

Type 11 is what you need, just like FalconSedanDelivery's. Only problem is, he's a drag racer, and typical of them, his pictures don't show nearly enough....

Back to point 2...

When it come to chassis dynos, with respect, the loss of power on a chassis dyno on any car with a converter is more like 39 to 63%. Aint no way a counterweight dyno will be sucking 25%. The C4/7.875" diff combo will always take at least 39% off the flywheel hp with the best torque converter, and the 3 speed manual /7.875" combo removes 26.5% based on extensive experience.

That's why drag racing is the be all and end all, the counterweight method of measuring torque reaction isn't perfect. Loading a car up on the tarmac, and maybee a little VHT glue is.

Had the discussions before.

I have personally seen here (80Foxes 3.3 C4 auto Fox Mustang) 14% loss as a figure given on some test equipment, but when you log it against the Moroso Computer or any other, a C4 auto that isn't transbraked or extensively shift kitted is a mandatory 40 to even 63% sap on the flywheel hp, so what you see at the wheels is always less 40 to 63%.

I agree with everything else.

See my previous posts.

Chassis dyno tests on a approx 350 hp net small block V8 Car Craft tested in an article show the total trans and axle and rolling resistance losses

Powerglide 35% total with 5.4% loss from the gearbox

Ford FMX 39% total with 7.7% loss from the gearbox

Mopar A904 39% total with 7.7% loss from the gearbox

Ford C4 41% total with 5.4% loss from the gearbox

Turbo Hydramatic 350 45% total with 11.1% loss from the gearbox

Turbo Hydramatic 400 50% total with 14.4% loss from the gearbox

Mopar A727 51% total with 14.7% loss from the gearbox

Ford C6 60% total with 20.0% loss from the gearbox

Figures don't lie, any dyno test is just a back to back comparo on the best combo of the day. So is drag racing a car over the standing eighth or quarter mile

viewtopic.php?f=76&t=71753&p=551115#p551115

viewtopic.php?f=1&t=72006&p=553034#p553034

viewtopic.php?f=3&t=19190

viewtopic.php?f=76&t=71891&p=552370#p552370

congrats Bob and good job! I also think you will find some more power with additional tuning. Good luck

congrats Bob and good job! I also think you will find some more power with additional tuning. Good luck