hotrodguy":y9vmm5ny said:ludwig, could you be more specific about those Mustang 6 pics, I searched and could not find anything. much thanks Randy

, the links to Jacks "Jack Collins X head" are off the internet.

His car was a Locost, and they operate a gentelmans arrangment where all the info is there.

Its links aren't any longer on FordSix.

In its first incarnation in the JCX Locost 200 six, had an alloy headed Aussie CrossFlow with six Suzuki RC40 Mikuni Flatside carbs.

Then he went to twin CDS175 Zenith Strombergs with his wifes chopping board modified...as a heat insulator.( :rolflmao: True strory...

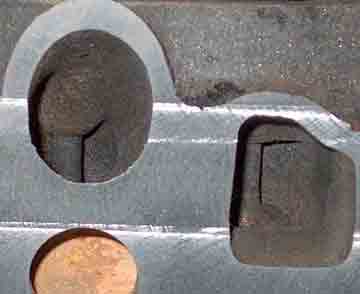

This is the head swap he did

archive/XF200ci.php

http://www.locostbuilders.co.uk/photos. ... G_0152.jpg

http://www.locostbuilders.co.uk/photos. ... G_0158.jpg

There are no longer any copies of the pictures of the six carb intake, but its just like this Pinto 2000 EOA engines set up, on a handmade alloy tube intake. Rob Wards carbs on the X-flow six. Only issue was how close the carbs were to the early small cap Duraspark distribtor, but these days, a mike1157 / thesameguy EDIS6 sawp will remove the ditributor entirley.

With the stock head casting, and killer modifications like the Aussie three DCOE 45 set up made by Paul Knott, there is a true 280 flywheel hp from just 170 cubic inch engine that made 105 hp gross, 72 net flywheel hp or just 57 rear wheel hp. A 289% boost in power.

https://www.youtube.com/watch?v=4QTgb4knAuI

If you did the Ak Miller four 1-3/4" internal diameter braised on flanges, or linked rob Ward style as Paul Knott Autos XK racer is for its 6 1-1/2" runners and used the 240/260 Z Hitachi to 390 cfm style intake manifold adaptor, leaned the engine over, you'd have ample room for the 500 cfm that two SU HS6's flow. The Keihin's flow about 545 cfm all up. So a good Holley 4-bbl carb feeding the log head externally will easily make well over 160 hp before a more modern cam and better valves are added. The L series engines run similar porting spacings to the Log head six, with the two inner cylinders intake runners way wider spaced than cylinders 1, 2 4 and 5. So the same boost with a good 4-bbl over three 45 DCOE's can be expected.

The engine is easy to slant. We use the old V8 cross member, and tilt the engine over just on the engine mount perches.

Then you could then go with a single steel plate to weld or bolt an intake onto it and also the exhaust header too. When I was thinking about doing it was going to either cut the plenum off but leaving the intake ports as long as possible or just open the top of the plenum just so could get inside to port the intake runners.

Then you could then go with a single steel plate to weld or bolt an intake onto it and also the exhaust header too. When I was thinking about doing it was going to either cut the plenum off but leaving the intake ports as long as possible or just open the top of the plenum just so could get inside to port the intake runners.