The multiple spark ignitions have coil modules which cost money to make, and a dollar saved is a dollar earned. Detriot started the whole with Presolite and Chrysler moving to solid state ignition first. Ford was sued over the Autolite/Presolite purchase, and had to rework the Autolite system through Motorcraft. AMC used Presolite igntions, but then had to move to Ford ignitions

Through the 70's and 80's, the Big Four pumped money into white box suppliers like Autolite, Presolite and AC Delco Remy first up, and then decided to work on the Big Threes systems. Chrysler created the worldwide use of electronic igntion, and then Congress made them sell off the family silver to Email, Bosch and that's where Pertronix got there conversion kit from...all Chryslers hard work with Presolite.

AMC bought Ford ignition systems

GM invested in there own system

Chrylser basically did its owm thing with White box suppliers, then got its fingers burnt and there systems got copied snd used by the Japanese (Mitsubishi, Toyota, Nissan via Mitsubishi Aerospace, Desno, Hitachi, Bosch in Australian made Silent Shaft 2555 engines used a Ford, Holden and GM Holden J car igntion system which Hyundia and Toyo Kogyo [Mazda] copied).

It was all in bred stuff. The goal was to make a better, cheaper igntion that met the performance, emission and economy targets.

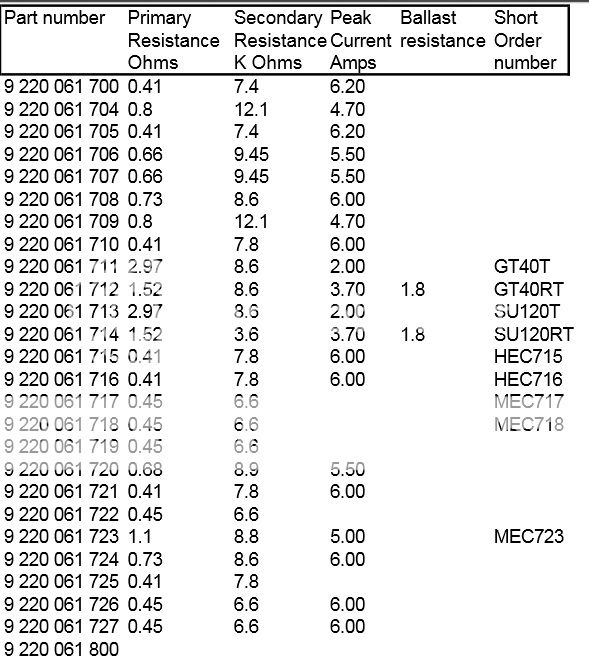

The coils primary and secondary Ohms resistance spec issue is there to condition the right kind of spark, at the right time, without spark saturation. Ford had

one coil type for the Red and Green strain relief Duraspark I, and

another for the yellow and Blue strain relief Duraspark II..

The Brown strain relief Duraspark III is the most advanced kind of rotator distributor system ever, it has an EECII or EECIII ecm computer to periodically manage a crank position sensor to dynamically control where spark happens. Each variant had different coils to suit the igntion type.

Not all igntions are ballested. Ballasted (resistor type) electronic igntion systems exist not to throttle back, or educe peak voltage as is mistankenly thought, but as a way to place load on the ignition system to drastically improve start up after the coil has heated up, and to reduce power consumption. Its like a quick light off catalyst, it effects a change on the the cold performance of an engine part. A catalyst converts heated gas into an oxidation reaction. A ballast resistor brings on a secondary voltage change by Ohms Law. It uses Ohms law to load the coil and get it working with reduced voltage, not as a means of reducing voltage to the coil all the time.

The Duraspark I remains, IMHO, the singularly best system ever for a rotator shaft ignition, in terms of fat spark, and it got used until a cheaper option was found.

The Duraspark II was a downgraded because the electronics suppliers found another way to get as good a result, with less cash. So the DS II was a cost benefit/Quality/rpice trade off igntion.

The HEI was designed to do what the DUI does so well...incorporate the igntions and control box and coil all on the engine to ease assembly line work, just like the ALDL link...it was all designed to save cash while quickly scrweing together Louis Chevies and Henry Fords in Motor City.

When GM or Ford change a ballast resitster value, and the primary and secondary KiloOhms resistance, they do so to optimise spark (quality) and cost (price).

When GM went in1984 to Direct fire distributorless ignition on the Buick 3.8 with an aggressive 48 degree total advance, it was to save cash to make power and economy gains. They changed the whole igntion system to reduce igntion coil spark saturation, and get the right kind of spark quality to help emissions, durability. Waste spark hit town in 1988 with the GM 3800 version. Its whole reason for being was to reduce spark saturation

See page 2

http://www.underhoodservice.com/servici ... engines/2/

If you test a coil with an ohmmeter, the test specs are 0.5 to 0.9 ohms for the primary terminals under the coil, and secondary resistance of 5,000 to 8,000 ohms at the high-voltage terminal.

See how tiny the primary resitance is.0.5 to 0.9 ohms is very small compared to an HEI or DSII.

5,000 to 8,000 ohms secondary resistance is 5 to 8 K Ohms

MSD, DUI are all trying to get the best results from a stock kind of rotator distibutor.

Here is what happened in the interbred Australian Bosch based distributor, which was a centrifugal and vac advance Autolite 1969 351 Windsor base, used on 318 Chryslers and 253/308/304 GM Holdens, and then later on gutted powered by a EST module in Holdens for years.

The Ford version was called the Austrlian X-flow or Cleveland Duraspark, the GM Holden HEI, or the Chysler ELB. They used a coil with a specfic primary and secondary ohm resistance, and noted if it was ballast resistor equiped.

/viewtopic.php?f=3&t=75528

9-230-064-705 came out of a 3.3 or 4.1 auto falcon or TF Cortina high comp engine.

9-230-064-710 manual 3.3

9-230-064-711 4.1 auto

9-230-064-716 came out of a XE 4.1 auto

Specs are generally a coil with Primary Resistance of 0.45 Ohms, Secondary Resistance of 6.6 K Ohms, if its not ballasted.

from ADDO in April 21, 2003

viewtopic.php?f=3&t=4163

Distributor test:

Connect a volt meter & an LED test light to the blue/white wire on the ignition module.

Cranking over the engine should get a pulse through the volt meter and the LED light also pulsing. Distributor test is OK if it does so

Coil test:

Using an ohm meter check the primary terminals, should read 0.45 K Ohms. Check secondary terminals, reads: 6.6 K Ohms

Put timing light on lead running from coil to distributor, you should get strobe. If nothing, no strobe, then a reluctor problem. Should get same result when tested on all spark plugs.

Check with Volt meter on both terminals. Voltage should fluctuate and LED pulse.

The old Ford Falcon Ignition coil - XE 3/1982-9/1984 6 Cyl 4.1Liter was the same as the XD/XE and Aussie Ford Broco/f100/250/350 3/1979-2/1982 8 Cyl 302 C 4BBL and 351c 4bbl.

They were standard oil fitted coils by Bosch with codes like:-.

Bosch - 9220-061-444, 9220-061-445, 9220-061-448, 9220-061-449,

Bosch - 9220-061-451, 9220-061-453, 9220-061-455, 9220-061-460,

Bosch - 9220-061-461, 9220-061-462, 9220-061-465, 9220-061-466,

Bosch - 9220-061-480, 9220-061-483, 9220-061-485, 9220-061-600,

Bosch - 9220-061-601, 9220-061-603

http://apps.bosch.com.au/AAExtranet_Tec ... lspecs.pdf

They were replaced with this

http://www.sparkshop.co.nz/Catalogue/Pr ... t/69MEC717

.

.  .

.

.

.  .

.