Basically, lobe center is largly irrelevant, as all Fords turbos used a less than ideal 109 lobe center.

The main issues are making one carb supply even fuel air mix to all six cylinders.

You always get incipient detonation, and that goes undetected, giving rise to this

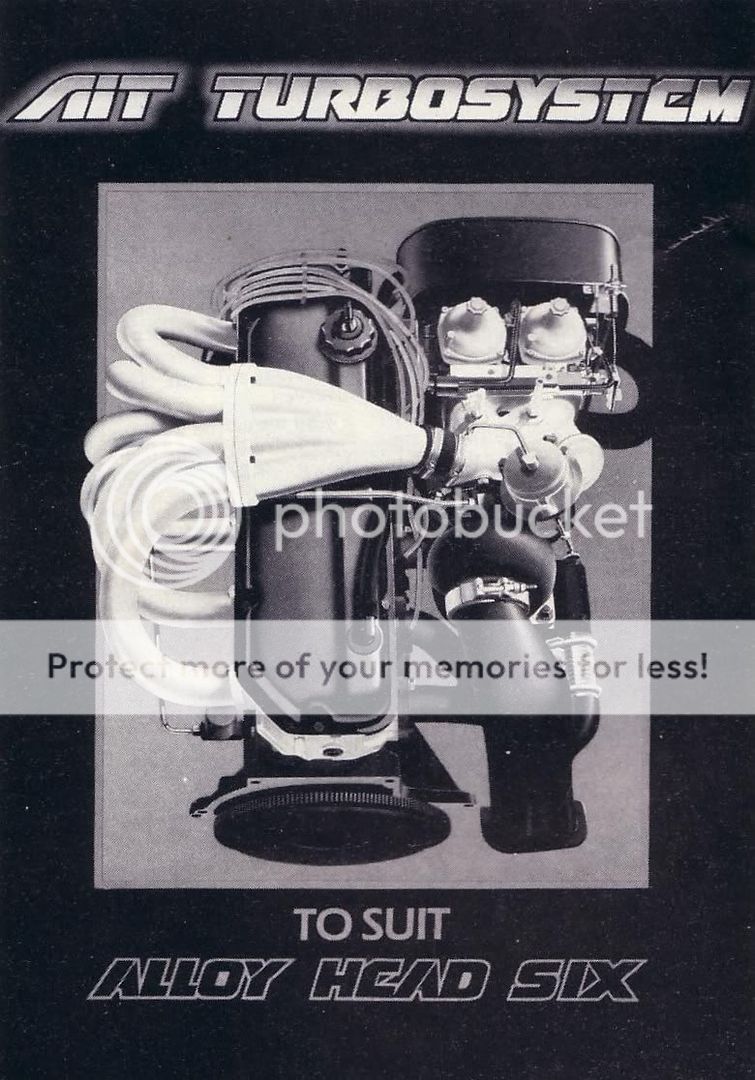

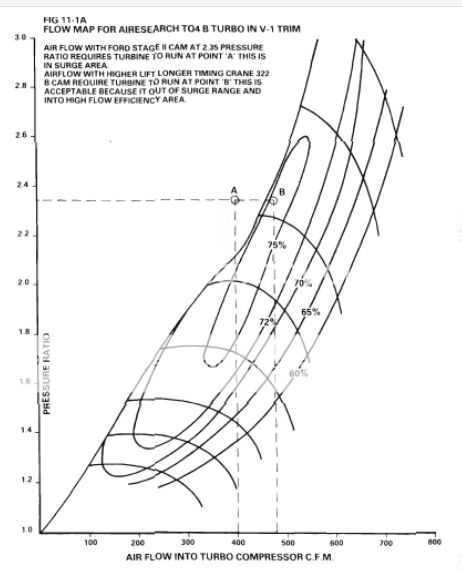

You do need at least a bigger than T03 60 Series turbo if your 15 pounding it. See

Lincs' 200's sizing chart.

/viewtopic.php?f=22&t=24859

Linc's 200":dsl7wjr5 said:

Turbo is a Garrett brand (AiResearch) that is an ACTUAL Garrett brand turbo that I bought on ebay, not some Chinese "Super T-70" junk that ssautochrome sells. It is S-3 Trim compressor, with "O" trim exhaust and .68 A/R turbine housing.

I used this guide:

from this article:

and was LUCKY to find just that on ebay, for $275, brand new in the Garret box.

You need to read the forums on this site for THREE MONTHS before posting any questions:

There is so much info there, it is staggering. A lot of it is hardcore, so stay in the shadows - - look, watch, listen, and learn - and SEARCH before posting new questions.

Also, a long time ago I bought the "Turbochargers" book from Hugh MacInnes.

[/img]

Knowledge is power...and doing your homework ahead of time will help tremendously. An ounce of prevention is wrth a pound of cure.

Boost creates a psychotic air fuel response, and Weber 2-bbl carbs feeding six cylinders from one 22 inch long 1.6 inch diameter log with six 90 degree bends are the worst known to man system to tune. Weber carbs are also air calibrated more than just about any other carb system, the Variable Venturi 2700 and 7200 from Ford 1977 to 1991 were too. Boy are they AKWARD!,

Specific to Webers, they require step wise idle, progression/transition and, lastly main system calibrations. Like this.

Unlike triple Weber DCOE 45's, they also have power valves because they are not port on port, independent runner systems. And that means the power valve spikes fuel delivery as well

And you don't even start calibration until you do six thingsl

Firstly, the ignition settings for the planned power out put are cast is stone. A turbo will have a flat advance curve, with static idel at as much as 16 degrees, somtimes 20. A Durspark II has a 5 degree cranking advance that then drops back if you wire it right. Then look for 25 degrees total at about 2800 rpm to avoi the Big Bang.

Secondly, the needle and seats are uniformly unreliable and normally undersupply, creating the major starvation issue which people think is a carb calibration jet size matter. You have to frequently assure yourself that its not the main neelde and seat by keeping a really good one, as a checker. Renew them with a 2.5 needle of name brand quality if the checking needle and seat runs better than the inservice one. Pierces are likely to be the best quality.

Third, the float set up is real finicity, and you have to know the differences between the five types of 38 DG series floats and bleed back systems. Often the economiser boss has incorrectly machined slots, whic ensures the carb becoems and irratic pile of dog doo doo to tune.

Fourth, the fuel pressure was controlled by bleed back on all post 1973 to 1992 2-bbl Weber European, British and Australian Fords, but not so in US Holley Weber Fords. Bleed back as a means of maintaining fuel flow but reducing pressure to 2.5 to 4.2 psi is not understood at all in the USA. I've tried to educate on it. Actually, Ford USA used bleed back in the air controlled Variable Venturi 2700 and 7200 carbs, and it works via the Trip Minder Vapor valve, which has a bleed back drilling in the 1986 Areostar's, and the part is still around. No matter, most 38 DG Webers come with a bleed back line, and the Jeep guys hook it up to the common 232 cubic inch in line 1 or 2-bbl six cylinder fuel filter.

You can use Mr Gasket, Aerometive, or another kind of Hobbs switch, but you have to control fuel pressure without flow restriction, and on a turbo, you have to spike the fuel pressure at no more than 4.2 psi per pound of boost. There are a number of ways of boost referencing the float bowl by

http://vb.foureyedpride.com/showthread. ... -Fantastic

Post #8

http://shoptalkforums.com/viewtopic.php?t=121925

Using carbs because i have them, No mod rings, look at the picture of my carbs that turbobaja posted, from that an fitting a 3/8" hardline goes into my boost stream to catch a good flow of pressurized air.

Fifth, the air correctors and jets and needle and seats always ingest crud, and create irregular running.

Sixth, emulsion tubes (well tubes) control the transition spike delivery. You can select other ones to control air fuel ratio to get the right kind of flat or flat fuel curve. David Vizard describes it here:-

https://www.youtube.com/watch?v=1pkFSA_rRFI

Seventh, withall 38 Webers, but even more so turbo Webers, the Positive Crank case Ventilation system has to replicate the factory Cologne V6; the Wagner adjustable PCV valve is a pretty good imitator of the German Cologne baffled and balanced system. Get it wrong, and a Weber 38 with a Hybrid T04 Sierra Coworth RS 500 turbo will surge and require detuning, and suck in a lot of octane killing oil which will have you needing Hi Test with an octane booster.

http://retrorides.proboards.com/thread/95321?page=2

Being doing some more research into the engine set up etc and found a few simple thing's i didn't know.

The pipe from the air filter feeds straight into the head cover and then into the turbo, why would that be?

The top hat thgat we are talking about has a mesh inside, like so and then found that it has a tiny dump valve fitted inside the left hand tube, so quiet i never hear it!

I haven't managed to get it up in the air yet so no pics of the manifolds but i will put some up!

Been looking at charge coolers compared to an intercooler, from what i have read a charge cooler would be best but for cost reason's i'm going to go for an intercooler and try and get a box for the carb made up.

The cam duration of the BroadSpeed Essex 218 to 230 hp net V6 2994 cc engine was 256 degrees lift at lash and 363 thou lift on a 1.47:1 rocker with solid lifters. 109 lobe center on an 7.5:1 compression ratio engine with one 1.07 Weber 38 mm carb. Stock engines were about 138 hp net. Totally stock engine with a carb box, electronic igntion, and IIRC, 9 pounds of boost. Holset 3LD turbo. Compression down from 8.9:1 stock. Known as a very poorly matched engine stock, with poor castings, Heron type pistons which were heavy and hit the valves on high lift cams, rocker valve stud stability problems, crank pin and big end oiling problems that actually went away when the engine was absolutely thrashed. A turbo Essex V6 in a TVR 3000 or Capri Bullet was an exceptional package, as subtle as an Uzzi at an Italian Wedding...but with pure 302/351 style GRUNT.

The cam duration of the Cologne 188 hp net 2794 cc engine was 276 degrees lift at lash and about 388 thou lift on a stock 9.2:1 compression ratio engine with one 1.07 Solex 38 mm carb ( a French Weber DGAS 38 in essence). 109 lobe center. Stock engines were 135 hp net. Totally stock engine with mild compresion drop, and carb, MAN air filter, and 5.5 pounds of boost. The boost was lImited so the compression ratio could stay the same.

It was a sustained 2.8 Aftermarket Cologne V6 option from 1981 to 1987, via Zaksped, Janspeed, Tickford, and Turbo Tecnics, but was Mechancial, or EFI from 1985 onwards.

This Cologne Turbo engine was a real screamer too, and in two continents (the British Isle and Europe) where gasoline was always three times the price of a US gallon, they didn't sell very well, but were exceptional engines with a turbo on them.

Both had seamigly over sized Garret T4 size turbos (the Broadspeed Holset 3LD is just as large) and had pretty much the same cylinder head 110 cfm CFM at 363 to 388 lift 28" H20 cfm figures for both the 183 cube 3.0 Lit

re and 171 cube 2.8 Lit

reengines.

Not a patch on the cubic inches of a 200 Ford, and no where near the cfm of the better large log heads, and way below the 165 cfm plus of a good 2V or Classic inlines head.

So basically, conventional theortical cam duration lobe center information is all rubbish on an airflow starved Ford six cylinder engine, as it is on any OLD overhead valve Ford V6.

As long as the intake manifold doesn't starve like

Lincs200 did under almost 20 pounds of boost, and you use good quality pistons with the right ring gap, you can run any cam you like. That rules out Sivolite HSC 2.3 pistons.

IIRC, on the Ford Tickford Capri 2800 turbo, the upraed Cologne 205 hp Tickford V6s, some of the aftermarket cams used the later Electronic Fuel Injection version which had 114 lobe centers, but they didn't

need it unless they had the later EECIV fuel injection.

Source:

Ford of Britians English Dagenam Essex built 60 Degree V4/V6 cams:

http://camshaftsuppliers.com/fordessexcamshafts.html

Ford of Germany's Cologne built 60 degree V4/V6 cams:

http://vb.foureyedpride.com/showthread. ... an-changes

Stock Cologne V6 of the 1.8/2.0/2.3 and later 1985 2.4 EFI were 264 to 268 duration and 380 thou lift cam engines, while the Saab V4 had 283 degrees duration and 380 thou lift. The 2.8 was halfway in between, but its a LOT of duration.

1972-1974 2.6 and 1974-1989 2.8 and 2.9 EFI's were 276 degrees intake /278 degrees exhaust with 388 thou intake lift and 382 thou exhaust lift

http://www.cosworth.hu/content/hasznos/V6 Engines/v6 engines.pdf

Camshaft specs were a lot like the Cologne Pinto 2000 and 280E Mercedes Benz engines:

Solid lifters, huge duration, low lift with low rocker ratios, and they worked just horriably with Standard gas with an 8.2:1 compression ratio when designed for Super gasoline and 9.2:1 compression.

An example. The US 280E lost 38 to 52% of its power just by the compression ratio drop required to run 87 Octane and pass the NOx requirements verses the European engines. Exactly the same with the 2.0 Pinto and 2.8 Cologne. That's a HUGE loss.

Aftermarket US cams had rip off Small Block Ford 255/302/351 intake lobe profiles of 244, 256, 264, 266, and 270 duration on the intakes, and gave better results than the stock 2.8 cams.

http://www.compcams.com/catalog/144_145.html

260 and 264 Racer Walsh cams were similar to Isky F4 260 degree/425 lift and F66 264/ 448 grinds. Better results with lesss duration, but more lift and 50 thou intensity.

http://www.racerwalsh.zoovy.com/product/RWA6411/2628-V6-stage-1-Camshaft-RWA-6411.html

http://www.racerwalsh.zoovy.com/product/RWA6412/2628-V6-stage-2-Camshaft-RWA-6412.html

The last Eight (8) aftermarket cams cams don't go up on stock duration very much because Cologne cams are solid lifter, and need more lift and compression and lobe center to improve power, but low end torque is always missing

http://www.kentcams.com/images/manf-images/camshaft-12.jpg

From ages ago...

Lasly,

http://fordsix.com/forum/viewtopic.php?f=22&t=69602

xctasy":dsl7wjr5 said:

Yeah, the Motorcraft 5200 or 2150 will love a nice turbo.

The advantage is that a return line carb can be boost referenced, and you'll not have to modify it at all except put good gaskets into it.

The Holley Weber branded Motorcraft 5200 series has a return line, also found on the 38DGAS used on the 2.8 Colonge engines.

You just need to follow the Essex 60 degree Broadspeed, via a sealed box

http://www.capripower.co.uk/boardold/lofiversion/index.php?t4032.html

or the Cologne 60 degree Zakspeed/Janspeed turbo set ups.

http://i1215.photobucket.com/albums...bo188hp206lb-ftCologneV6VIEW3_zps48a1b624.jpg

See also

http://retrorides.proboards.com/index.cgi?board=readersrides&action=print&thread=95321

A fuel regulator on the return line can ensure the carb is under differential boost. Does10's describes how to boost reference the ppower valve.

Have a go...

In the words of others

http://www.the510realm.com/viewtopic.php?f=8&t=11371

If you are planning to use the Weber 32/62, in a blow through application,, you will need to use a pressure regulator with boost compensation on it for sure, fuel must stay 3.5 PSI ahead of boost. Fuel pump MUST have good volume also, as do supply lines. You will need to run a return line to the tank, with a restriction in it. Start now to track down a NITROFIL float for the Weber! It came on the 5200 series carb used on Pinto's, Capris, etc, licenced to Ford. This will not collapse under boost.

I modded my stock vacuum advance to be boost retarded, and, re worked the advance curve.

Methanol injection as a supplemental charge cooling is good, as is a good size oil cooler and better radiator. My system is self pressurizing, using a Hobbs switch for triggering it.

IF>>>you are going to do a blow through, you will need a box built for the carb to be sealed into. If you are going to do a suck through, that has it's own set of parameters to be delt with.

Stay small with your turbo choice, as you will have a much more drivable and resposive car overall.

Plan for a wastegate and compressor blow off valve also. You should be able to find a nice blow off at the wreckers, off a Talon, they are more than adequate for our needs.

And lastly, the 5200 is a 32/36 Weber, and see this kit

http://www.turbogemini.com/Blow Through Carby Kit.htm

and finally

http://www.homemadeturbo.com/forced-induction-7/blow-through-carburetor-turbo-setup-95522/

.

.