Learning as I go. I've got capable mates that are great with the wrenches but I need to get them the correct parts to work with.

My D8 head is being worked over and converted to 2V by a forum member who knows what he is doing. Full treatment. Everything in the handbook.

I have a '79 DSII that will be swapped in at the same time that the head and carb get swapped in.

Will later have a driver profile, low/mid RPM cam.

Will soon have the speed daddy headers

Will eventually have a T-5 with 3.5 or 3.73 rear end

I live at 6000 feet elevation.

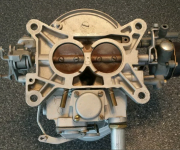

I'm going with the Autolite 2100. I'm thinking 1.08 or 1.14.

Is there a specific year range I should be looking for? Does it matter what vehicle or what engine my donor carb comes from?

Does my altitude effect my ventri choice?

Any thoughts on jetting?

Anything else is need to be considering regarding the carb?

Thanks in advance for your help!

My D8 head is being worked over and converted to 2V by a forum member who knows what he is doing. Full treatment. Everything in the handbook.

I have a '79 DSII that will be swapped in at the same time that the head and carb get swapped in.

Will later have a driver profile, low/mid RPM cam.

Will soon have the speed daddy headers

Will eventually have a T-5 with 3.5 or 3.73 rear end

I live at 6000 feet elevation.

I'm going with the Autolite 2100. I'm thinking 1.08 or 1.14.

Is there a specific year range I should be looking for? Does it matter what vehicle or what engine my donor carb comes from?

Does my altitude effect my ventri choice?

Any thoughts on jetting?

Anything else is need to be considering regarding the carb?

Thanks in advance for your help!