Hi,

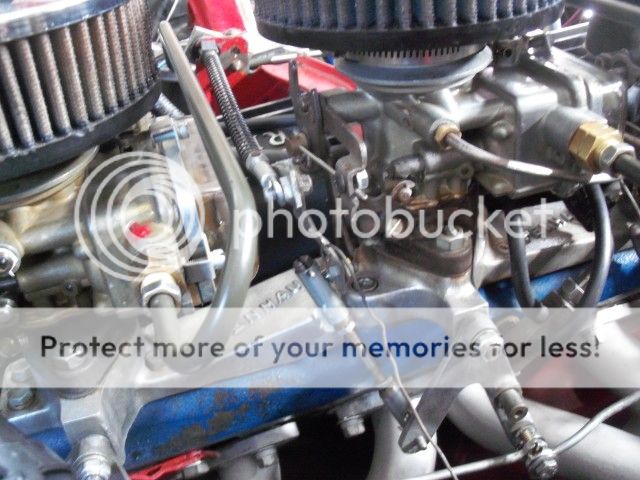

We have a 72 Comet with the 250 six and a Carter RBS carb. Were able to score an Offy 3 carb manifold and some 1904/1908 Holley 1 barrel carbs. I want to rebuild and try out each carb individually on the original head. That way when we do the conversion we can at least start out with "good" carbs before fighting the multiple carb linkage and calibration adjustments.

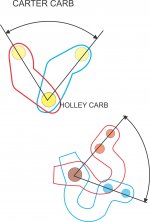

The Holley carb will bolt on to the intake but the throttle linkage is a problem. The cable from the as pedal is a "pull" for full throttle and a "push" for idle. The lever on the Holley is set up for a "push" for open and a "pull" for closed. Has anybody done a Holley conversion for this setup? I know the Holleys were used on earlier cars but don't know what the linkage looks like.

Thanks,

John in Kalifornia

We have a 72 Comet with the 250 six and a Carter RBS carb. Were able to score an Offy 3 carb manifold and some 1904/1908 Holley 1 barrel carbs. I want to rebuild and try out each carb individually on the original head. That way when we do the conversion we can at least start out with "good" carbs before fighting the multiple carb linkage and calibration adjustments.

The Holley carb will bolt on to the intake but the throttle linkage is a problem. The cable from the as pedal is a "pull" for full throttle and a "push" for idle. The lever on the Holley is set up for a "push" for open and a "pull" for closed. Has anybody done a Holley conversion for this setup? I know the Holleys were used on earlier cars but don't know what the linkage looks like.

Thanks,

John in Kalifornia

congrats on scoring the Offy intake and Holleys they're one of my favorite looking 3x1V setups with the Glass Bowels!

congrats on scoring the Offy intake and Holleys they're one of my favorite looking 3x1V setups with the Glass Bowels!