You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cast Valve Cover Grommet?

- Thread starter 65coupei6

- Start date

All the major parts stores carry them.

HOWEVER you will suck oil into the PCV valve. One choice is move the valve via an 2" hose to raise the hose above the valve cover.

The C.I. valve cover is just a copy of Cliffords cast valve cover, a good looking piece of junk.

From an engineering design the cover should be 1/4" higher to clear a decent baffle over the PCV valve just like the factory stamped steel cover.

You can use double valve cover gaskets to raise the cover.

You can then install a sheet metal baffle to the top of the cover. The 4 bosses are cast into the cover, but need to be drilled & tapped to fasten an OEM style baffle.

That's why they pay factory engineers to do the design correctly, rather than a parts copier of a poorly designed product.

HOWEVER you will suck oil into the PCV valve. One choice is move the valve via an 2" hose to raise the hose above the valve cover.

The C.I. valve cover is just a copy of Cliffords cast valve cover, a good looking piece of junk.

From an engineering design the cover should be 1/4" higher to clear a decent baffle over the PCV valve just like the factory stamped steel cover.

You can use double valve cover gaskets to raise the cover.

You can then install a sheet metal baffle to the top of the cover. The 4 bosses are cast into the cover, but need to be drilled & tapped to fasten an OEM style baffle.

That's why they pay factory engineers to do the design correctly, rather than a parts copier of a poorly designed product.

Will it suck oil in even with a baffled grommet? I found a Morose 68772.

https://www.summitracing.com/parts/mor-68772

https://www.summitracing.com/parts/mor-68772

Yes it will. You need to use a baffled grommet in addition to raising the PCV above the valve cover as shown.65coupei6":33yen7kq said:Will it suck oil in even with a baffled grommet? I found a Morose 68772.

https://www.summitracing.com/parts/mor-68772

I plan to go back to the factory valve cover myself to eliminate this problem.

I wish someone with an engineering background would design a decent cast valve cover rather than go for looks or just a copy.

Word, wsa111!.Got it in one.

Ford spent a bunch of money putting baffels and non return flapper valves on the later 200 and all OHC Ford engines. Same with the 5.0.

Baffles are flow-directing or obstructing vanes or panels used in vessels /tanks.

Ford additionally has some 90 degree bend PCV's. OHC ones don't have a 90 degree bend beause the baffeled flapper valve in the crankcase controls atomised oil laden flow.

I could write a book on how much smarter FoMoCo was from the 1969 to date on this....the aftermarket spends most of its time annualing the great work Ford did. Any 69-80 Pinto, 78-85 carb Fox Ford uses these great systems. As soon as the roller rockers, big cams, and aftermarket rocker covers go on to the cylinder heads, whammo, instant oil down due to the removal of the stock baffel and 90 degree PCV. Same with turbos and EFI.

Way back in the Noughties, Doug (MustangGeezer) found the same issue when he changed his carburation...the Positive Crankcase Ventilation valve needs some kind a way to reinstate the factory baffel, and when power increases, blow by increases proportionally. Ford make a variety of flow rate restrictions, depending on application, but its not the PCV, its the baffle required to prevent a peak flow of atomised oil vapor from the crankcase, stired up by the valve gear, from flowing into the PCV.

You can use standpipes to space the valve away, but the Primary Problem is that aftermarket rocker covers have no baffel.

In that istance, your better off shelling out on a balanced flow AE Wagner Adjustable PCV valve like mark_hagen used when confronted with the same issue.

It has always been an issue with 5200/6500 Holley Webers and Weber 32/36's, but the Root Cuase is the rocker cover baffel and how there needs to be a baffel, flapper, or height related standoff.

/viewtopic.php?f=1&t=73925

All Six cylinder Fords came out with mild cam timing from 240 to 256 degrees, and the moment you go to 2-bbl carbs and you change the cam you need to

A. get rid of the stock pcv valve and

B. run the pipe from the carb to a baffled oil, seperator or catch tank.

C. If you can't duplicate the stock 2.0/2.3 Ford Holley Weber PCV set up, the 3rd solution is the Original Poster Mark's.

It's important to note three things.

1. Firstly, any PCV that vents to the carb also needs an air cleaner mounted line to the oil fillter cap. There needs to be a PCV line and a line to the oil filler cap, and a baffle under each.

Like this post 1978 rocker cover

(NB//The red squares are where the adjustable rocker gear I used hits the standard Ford baffels. Anytime you use earlier 1971-1974 M code 250 2V or US 1960 to 1966 adjustable rocker gear, they always hit the later Fox and Maverick/Monarch/Granada rocker cover baffels. You need to stack cork rocker cover gaskets or make up a spacer plate to move the rocker cover up, and use some longer hold down bolts).

Without a line in an out, the PCV system won't work.

See this video. It's so common to do it wrong.

https://www.youtube.com/watch?v=XIw--72EKU0

2. Secondly. Without the baffels above, you have to revert to the way Ford from there first 2-bbl Holley Weber carbed 2 liter EAO Pinto engine in 1969 to the last of the carbed US 2.0/2.3 Lima OHC in the Ranger and Mustang Fox in the 80's. They did it using a baffled oil, seperator to stop the crank case ventilation pulses up setting the PCV port on carb instillations.

It is on every SOHC 2.0 to 2.3 liter carb engine from 1969 to 1988, and it sits here.

The installed intake manifold prevents it ever coming loose or falling out by itself.

There ws a last OEM Ford reference for it

The last OEM part number Ford gave F0ZZ6A785A or F0ZZ6A785AA. It has a 3/4" hole with tapered fit that just pushes into the hole in the block. It has a spring with a flapper valve inside to dampen the pulses from the crankcase blow by.

It works in conjuction with with a 3/8" internal diameter line to the rubber 1/8 inch by 1 inch grommet where the PCV valve sits.

that holds the common 3/8" hose PCV valve.

Here is how it looks on a 2.3 Lima block in the 1979 Fox Mustang/Fairmont/Zephyr engine bay

It is called a crankcase oil/air separator or a positive crankcase ventilator oil separator.

It helps to relieve the positive pressure that is built up in the crankcase. It is a box having one hose runing in and one running out. One of the hoses that run from it is connected to the PCV valve

Not having the PCV balanced and dampened before its hooked to the any of the Holley Weber or 32/36 and 38 Weber carbs often results in typical PCV jamed oen issues:-

- Oil consumption

- Bad idling

- Knocking engine (atomised oil in the inlet air causes a very low octane)

- Hard to start

- Bad to drive when driving off

- Vacuum leak like symptoms

The Third thing. We are often looking at turbo chargers, EFI or non standard , no longer 1-bbl engines that now have sixes that have totally different crankcase ventilation requirements.

When used, the system has to change to cope with blow by which is now directed into the carb.

The same EAO2.0 /Lima 2.0/2.3 catch can uses a two way system like the Capri RS Turbo, Mustang GT turbo, Mustang SVO and Merkur XR4Ti and Thunderbird Turbo SportsCoupe used from 1983 to 1988. Here is a common after market modification with an extra external catch can and blow by protection.

[/quote]

[/quote]

Ford spent a bunch of money putting baffels and non return flapper valves on the later 200 and all OHC Ford engines. Same with the 5.0.

Baffles are flow-directing or obstructing vanes or panels used in vessels /tanks.

Ford additionally has some 90 degree bend PCV's. OHC ones don't have a 90 degree bend beause the baffeled flapper valve in the crankcase controls atomised oil laden flow.

I could write a book on how much smarter FoMoCo was from the 1969 to date on this....the aftermarket spends most of its time annualing the great work Ford did. Any 69-80 Pinto, 78-85 carb Fox Ford uses these great systems. As soon as the roller rockers, big cams, and aftermarket rocker covers go on to the cylinder heads, whammo, instant oil down due to the removal of the stock baffel and 90 degree PCV. Same with turbos and EFI.

Way back in the Noughties, Doug (MustangGeezer) found the same issue when he changed his carburation...the Positive Crankcase Ventilation valve needs some kind a way to reinstate the factory baffel, and when power increases, blow by increases proportionally. Ford make a variety of flow rate restrictions, depending on application, but its not the PCV, its the baffle required to prevent a peak flow of atomised oil vapor from the crankcase, stired up by the valve gear, from flowing into the PCV.

You can use standpipes to space the valve away, but the Primary Problem is that aftermarket rocker covers have no baffel.

In that istance, your better off shelling out on a balanced flow AE Wagner Adjustable PCV valve like mark_hagen used when confronted with the same issue.

It has always been an issue with 5200/6500 Holley Webers and Weber 32/36's, but the Root Cuase is the rocker cover baffel and how there needs to be a baffel, flapper, or height related standoff.

/viewtopic.php?f=1&t=73925

xctasy":mgzyg2cb said:cr_bobcat":mgzyg2cb said:So how do you like that adjustable PCV valve? Is it worth the money? I've been looking at the thing and it's definitely intriguing...

https://youtu.be/nd92jPRH3YY?t=123

All Six cylinder Fords came out with mild cam timing from 240 to 256 degrees, and the moment you go to 2-bbl carbs and you change the cam you need to

A. get rid of the stock pcv valve and

B. run the pipe from the carb to a baffled oil, seperator or catch tank.

C. If you can't duplicate the stock 2.0/2.3 Ford Holley Weber PCV set up, the 3rd solution is the Original Poster Mark's.

It's important to note three things.

1. Firstly, any PCV that vents to the carb also needs an air cleaner mounted line to the oil fillter cap. There needs to be a PCV line and a line to the oil filler cap, and a baffle under each.

Like this post 1978 rocker cover

(NB//The red squares are where the adjustable rocker gear I used hits the standard Ford baffels. Anytime you use earlier 1971-1974 M code 250 2V or US 1960 to 1966 adjustable rocker gear, they always hit the later Fox and Maverick/Monarch/Granada rocker cover baffels. You need to stack cork rocker cover gaskets or make up a spacer plate to move the rocker cover up, and use some longer hold down bolts).

Without a line in an out, the PCV system won't work.

See this video. It's so common to do it wrong.

https://www.youtube.com/watch?v=XIw--72EKU0

2. Secondly. Without the baffels above, you have to revert to the way Ford from there first 2-bbl Holley Weber carbed 2 liter EAO Pinto engine in 1969 to the last of the carbed US 2.0/2.3 Lima OHC in the Ranger and Mustang Fox in the 80's. They did it using a baffled oil, seperator to stop the crank case ventilation pulses up setting the PCV port on carb instillations.

It is on every SOHC 2.0 to 2.3 liter carb engine from 1969 to 1988, and it sits here.

The installed intake manifold prevents it ever coming loose or falling out by itself.

There ws a last OEM Ford reference for it

The last OEM part number Ford gave F0ZZ6A785A or F0ZZ6A785AA. It has a 3/4" hole with tapered fit that just pushes into the hole in the block. It has a spring with a flapper valve inside to dampen the pulses from the crankcase blow by.

It works in conjuction with with a 3/8" internal diameter line to the rubber 1/8 inch by 1 inch grommet where the PCV valve sits.

that holds the common 3/8" hose PCV valve.

Here is how it looks on a 2.3 Lima block in the 1979 Fox Mustang/Fairmont/Zephyr engine bay

It is called a crankcase oil/air separator or a positive crankcase ventilator oil separator.

It helps to relieve the positive pressure that is built up in the crankcase. It is a box having one hose runing in and one running out. One of the hoses that run from it is connected to the PCV valve

Not having the PCV balanced and dampened before its hooked to the any of the Holley Weber or 32/36 and 38 Weber carbs often results in typical PCV jamed oen issues:-

- Oil consumption

- Bad idling

- Knocking engine (atomised oil in the inlet air causes a very low octane)

- Hard to start

- Bad to drive when driving off

- Vacuum leak like symptoms

The Third thing. We are often looking at turbo chargers, EFI or non standard , no longer 1-bbl engines that now have sixes that have totally different crankcase ventilation requirements.

When used, the system has to change to cope with blow by which is now directed into the carb.

The same EAO2.0 /Lima 2.0/2.3 catch can uses a two way system like the Capri RS Turbo, Mustang GT turbo, Mustang SVO and Merkur XR4Ti and Thunderbird Turbo SportsCoupe used from 1983 to 1988. Here is a common after market modification with an extra external catch can and blow by protection.

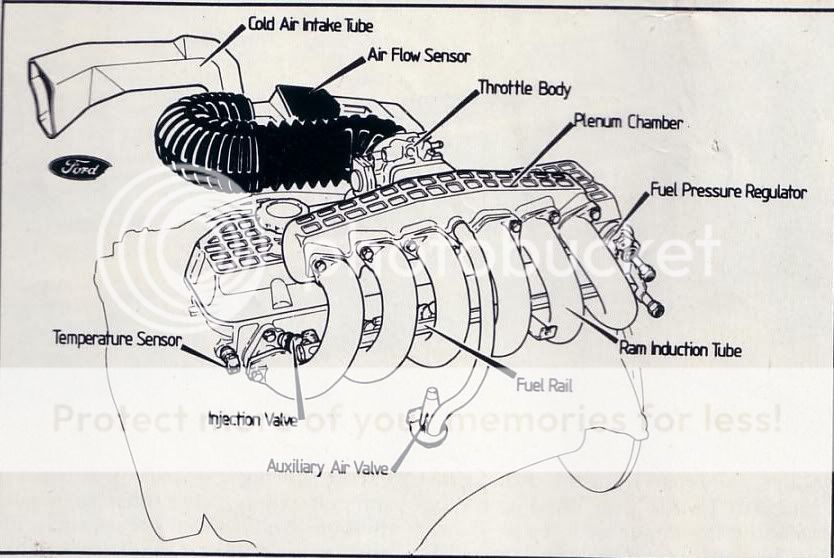

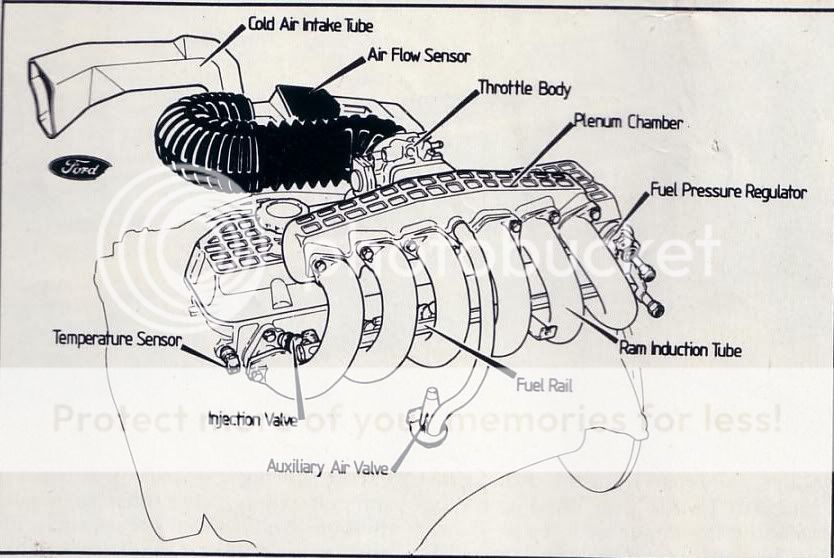

Just as another note for those of us going Speed Density (Map) or the flapper valve or Mass Air Flow MAF EFI.

That stuff requires different PCV system again.

When we drop from a 4.1 Cross flow, 4.9 Big Six or 5.0 Ford port EFI to a 4bbl intake EFI system like EZ, FAST or FITECH, we forget that it isn't a 4bbl carb system.

So much vac is created, it can squish the 3/8" PCV hose, and Ford doesn't even show the PCV system in the VECI chart on all of its engines.

All over the world, Ford Port EFI cars went to either an an Auxilary Air Valve (Bosch Pulse Width Modulation PWM-driven aux-air valve)

or Idle Air Control with a PCV hose on the Big Sixes and all other EECIV Port Injection cars and trucks

Only they didn't alway call it that, which makes it all a little bit hard.

Sadly, depending on diagram, the label it differntly, so there is a vast amount of things that can go wrong if you fiddle with a stock system

Since an aftermarket EFI mates the best of NASCAR 4-BBL or Pro Street Carb intake technology without the stock EECIV EFI port EFI manifold, you have have no PCV fit-up and an EFI engine will make awesome vacuum, and a will push the rings real hard from the get go.

That stuff requires different PCV system again.

When we drop from a 4.1 Cross flow, 4.9 Big Six or 5.0 Ford port EFI to a 4bbl intake EFI system like EZ, FAST or FITECH, we forget that it isn't a 4bbl carb system.

So much vac is created, it can squish the 3/8" PCV hose, and Ford doesn't even show the PCV system in the VECI chart on all of its engines.

All over the world, Ford Port EFI cars went to either an an Auxilary Air Valve (Bosch Pulse Width Modulation PWM-driven aux-air valve)

or Idle Air Control with a PCV hose on the Big Sixes and all other EECIV Port Injection cars and trucks

Only they didn't alway call it that, which makes it all a little bit hard.

Sadly, depending on diagram, the label it differntly, so there is a vast amount of things that can go wrong if you fiddle with a stock system

Since an aftermarket EFI mates the best of NASCAR 4-BBL or Pro Street Carb intake technology without the stock EECIV EFI port EFI manifold, you have have no PCV fit-up and an EFI engine will make awesome vacuum, and a will push the rings real hard from the get go.

"...Ford additionally has some 90 degree bend PCV's…."

sounds like the easiest.

Weren't (aren't) they the ones that look like the standard oem (seen in ur stand alone pic of the lill silver 'pregnant tube' having the hole on each end) but with a small (1/4 inch?) hard plastic 90* fitting on one end? Can't remember if that's before the PVC or after. If after it seems it wouldn't serve our (baffeling) purpose, just a 'reducer' for the carb line...

sounds like the easiest.

Weren't (aren't) they the ones that look like the standard oem (seen in ur stand alone pic of the lill silver 'pregnant tube' having the hole on each end) but with a small (1/4 inch?) hard plastic 90* fitting on one end? Can't remember if that's before the PVC or after. If after it seems it wouldn't serve our (baffeling) purpose, just a 'reducer' for the carb line...

65coupei6":3var2zgc said:Will it suck oil in even with a baffled grommet? I found a Morose 68772.

https://www.summitracing.com/parts/mor-68772

not much detail here.

Doesn't look like it gives enuff hight/distance (to eliminate the oil pass-thru) &

not sure if it fits the VC hole (1.22 inches it sez but where on the part is that measurement taken?).

I think it said theres a baffeling mechanism inside may B it doesn't need the 'distance' then?

I can attest that I had the same issues. I have the CI cover and the engine kept breathing in oil.

I ended up using these Moroso baffles (https://www.summitracing.com/parts/mor- ... oC4RPw_wcB) ; I epoxied them to the inside of the valve cover.

I then run a filter type breather on the front hole of the cover, a standard PCV valve on the rear hole. The PCV connects to an air/oil separator I picked up on Amazon (https://www.amazon.com/Godspeed-Univers ... +separator), and the it goes on to the vacuum source.

It's been on there for some time, and works great. Very little oil gets past the baffles, and whatever gets by is caught by the separator.

I ended up using these Moroso baffles (https://www.summitracing.com/parts/mor- ... oC4RPw_wcB) ; I epoxied them to the inside of the valve cover.

I then run a filter type breather on the front hole of the cover, a standard PCV valve on the rear hole. The PCV connects to an air/oil separator I picked up on Amazon (https://www.amazon.com/Godspeed-Univers ... +separator), and the it goes on to the vacuum source.

It's been on there for some time, and works great. Very little oil gets past the baffles, and whatever gets by is caught by the separator.

gus91326":2dxifrur said:I can attest that I had the same issues. I have the CI cover and the engine kept breathing in oil.

I ended up using these Moroso baffles (https://www.summitracing.com/parts/mor- ... oC4RPw_wcB) ; I epoxied them to the inside of the valve cover.

I then run a filter type breather on the front hole of the cover, a standard PCV valve on the rear hole. The PCV connects to an air/oil separator I picked up on Amazon (https://www.amazon.com/Godspeed-Univers ... +separator), and the it goes on to the vacuum source.

It's been on there for some time, and works great. Very little oil gets past the baffles, and whatever gets by is caught by the separator.

Where did you end up mounting the air/oil separator?

Geeze gus, U may have the pride'a havin a 'stickie'.

Gota pic of this work-around?

Drill'n tap 2 screws inta the underside of the cast VC, mount da baffle…but as asked - where is the catch can taped in (mount don't matter 2 me). Is there a nipple there 4 it 2 syphon off? Wasss up?

An what bout the return line to carb?

Thanks, G R E A T show, dude!!! (if I understand right)...

Gota pic of this work-around?

Drill'n tap 2 screws inta the underside of the cast VC, mount da baffle…but as asked - where is the catch can taped in (mount don't matter 2 me). Is there a nipple there 4 it 2 syphon off? Wasss up?

An what bout the return line to carb?

Thanks, G R E A T show, dude!!! (if I understand right)...

'S OK,(but justa blue box w/a question mark init). U got further than I would…

Is there enuff 'meat' in the VC to take the internal bolts w/o them showing thru to the top (or outside).

Is the nipple for the catch can on a riser outta the grommet before the PCV?

Tanks for the details (I'll just call U) Mr. Engineer.

Is there enuff 'meat' in the VC to take the internal bolts w/o them showing thru to the top (or outside).

Is the nipple for the catch can on a riser outta the grommet before the PCV?

Tanks for the details (I'll just call U) Mr. Engineer.