You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surging with a Carter YFA?

- Thread starter Asa

- Start date

Use the brown stripe.

Vacuum Motor assemblies have ratings.

Brown stripe will have a warmer temperature rating than the stone cold yellow stripe fitting based on what I've seen.

Snorkels will have vacuum motor controlled by the standard ACTS, so when hot air is called for all of the incoming air will be from the passenger side heat stove to the header.

(when Ford used headers like the 5.0 Mustang from 84.5 onwards, and the 90's 2.3/2.5 Ranger trucks, they used a clipped on pipe to the header.When updated, use this

or Stormin'Norman's hot air plenumb

)

)

Similar to the 1968-69 Firebird Exhaust Manifold Heat Shield

)

When cold air is called for, the flapper will open fully the snorkes will pull cold air from the radiator support (Big Foxes like the 80-82 Cougar xr7'S, Tbirds, F trucks), or about the battery area (all other Fox bodies, 75-80 Granadas, Monarchs, Versaillies)

Just like everything else...its got a temperature rating, one for the heat stove, and it depends on application. V8 dual snorkels have a different rating to other single snorkels.

Here is a near match to a Green TVS, a Red (but Pink looking to me) TVS, which won't have exactly the right leak pressure as per the 1985 Ford EVTM

The other CWM (TVS) colors for 3.3's are Blue and Green

For 4.9 Bix Sixes and other F-truck and E-Van vehicles, white and green

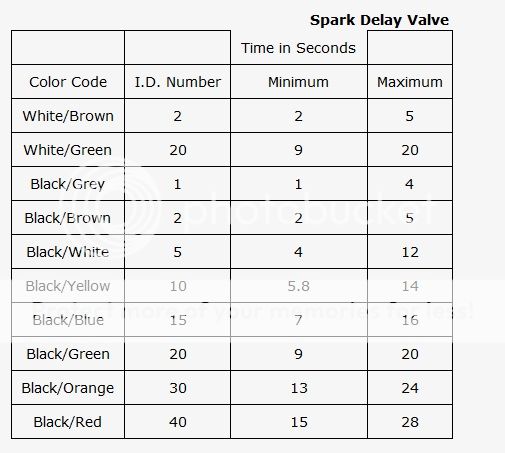

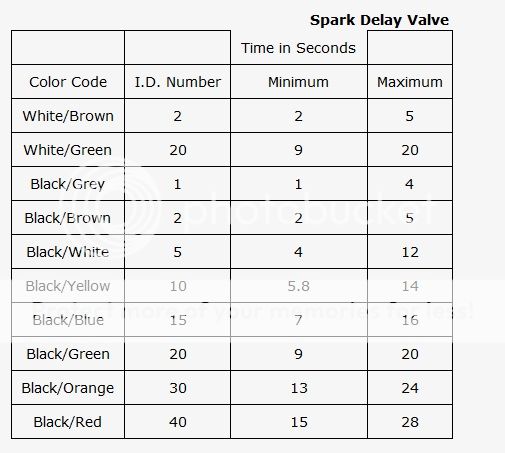

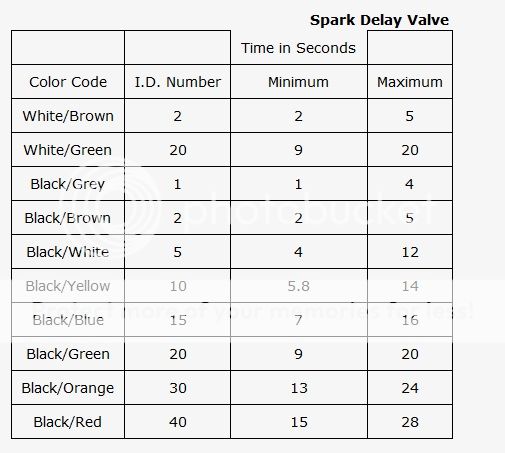

Ratings ex Ford Truck Enthusiasts, and FSP member Luke76

https://www.ford-trucks.com/forums/1157 ... ld-39.html

Note Well:

Bubba's yellow CWM numbers in last column are transposed (around the wrong way) according to Fords 1985 EVTM .

http://myzephyrs.com/vac_part_name.htm and everyone in parts list them as 9A995, or Air Cleaner TVS

See http://vb.foureyedpride.com/showthread. ... ost1819914

1bad6t...FordSix member.

Summary of all this....the 1946 Holley (stormin'Normans, my old Stang, everything 78-83 that was 3.3) and the YFA truck from 78-86, and Ranger from 83-88 ish, and Mustang/Capri from 83-86 ish, they all used the same emission system hardware. There is a lot of stuff in it, but I will say this. Hot climate, or freezing cold down to 14 deg F, I can vouch for how good a start up and warm up phase a 1-BBL Ford car is with this stuff. Really excellent. As I've said elseware, you could crack of dawn start it up away from home in a freezing climate, and you could leave the car locked, and have coffee at Tom's Diner listing to Suzzie Vega on repeat for 10 minutes, come back, and the cars still running and warmed it. Just the way the systems hav to operate in the LA Basin 7 mile, 12 point emissions test.

The parts from a wrecked 1-bbl Rnager or F-truck or 2.3 Foxcar are all there, once at a car yard, the little green, blue, white red and green components get prized off with a flat head screw driver, and then you pay extra for each one of the about 35 parts that make up the full emissions package. In fact, there are, by my reconing, 93 or so parts in any normal 1980 to 1986 1-bbl carb car.

Emissions engines use

1. more fuel,

2. make less power,

and

therefore,

3. naturally make more heat.

It's the ignition advance strategy, not EFI pulse-width or light off of the cats, that fixes the first four minutes of sub 65 deg F ambient and sub 190 deg F water operation.

All that smog crap doesn't help acceleration or power during cold start, BUT it does help cold start performance, but in terms of setting of the "inside state" warm up, cutting peak advance in high gear, and running less advance at the plus 35 mph area while warming up, really wipes off about a minute of warm up time. That was the main reason people hated early emissions gear, the cars woulds overheat....

Emissions Junk?

Vacuum Motor assemblies have ratings.

Brown stripe will have a warmer temperature rating than the stone cold yellow stripe fitting based on what I've seen.

Snorkels will have vacuum motor controlled by the standard ACTS, so when hot air is called for all of the incoming air will be from the passenger side heat stove to the header.

(when Ford used headers like the 5.0 Mustang from 84.5 onwards, and the 90's 2.3/2.5 Ranger trucks, they used a clipped on pipe to the header.When updated, use this

or Stormin'Norman's hot air plenumb

Similar to the 1968-69 Firebird Exhaust Manifold Heat Shield

)

When cold air is called for, the flapper will open fully the snorkes will pull cold air from the radiator support (Big Foxes like the 80-82 Cougar xr7'S, Tbirds, F trucks), or about the battery area (all other Fox bodies, 75-80 Granadas, Monarchs, Versaillies)

Just like everything else...its got a temperature rating, one for the heat stove, and it depends on application. V8 dual snorkels have a different rating to other single snorkels.

Here is a near match to a Green TVS, a Red (but Pink looking to me) TVS, which won't have exactly the right leak pressure as per the 1985 Ford EVTM

The other CWM (TVS) colors for 3.3's are Blue and Green

For 4.9 Bix Sixes and other F-truck and E-Van vehicles, white and green

Ratings ex Ford Truck Enthusiasts, and FSP member Luke76

https://www.ford-trucks.com/forums/1157 ... ld-39.html

Note Well:

Bubba's yellow CWM numbers in last column are transposed (around the wrong way) according to Fords 1985 EVTM .

http://myzephyrs.com/vac_part_name.htm and everyone in parts list them as 9A995, or Air Cleaner TVS

See http://vb.foureyedpride.com/showthread. ... ost1819914

mrriggs":wx7k697n said:I realize this is an old thread but it keeps coming up in my searches to make heads or tails of the vacuum system.

I found this list of FORD vacuum delay valves which may be more relevant to our cars than the list previously linked to.

The list was found here, http://www.1bad6t.com/Maverick/repair/emission_controls_02.html

1bad6t...FordSix member.

Summary of all this....the 1946 Holley (stormin'Normans, my old Stang, everything 78-83 that was 3.3) and the YFA truck from 78-86, and Ranger from 83-88 ish, and Mustang/Capri from 83-86 ish, they all used the same emission system hardware. There is a lot of stuff in it, but I will say this. Hot climate, or freezing cold down to 14 deg F, I can vouch for how good a start up and warm up phase a 1-BBL Ford car is with this stuff. Really excellent. As I've said elseware, you could crack of dawn start it up away from home in a freezing climate, and you could leave the car locked, and have coffee at Tom's Diner listing to Suzzie Vega on repeat for 10 minutes, come back, and the cars still running and warmed it. Just the way the systems hav to operate in the LA Basin 7 mile, 12 point emissions test.

The parts from a wrecked 1-bbl Rnager or F-truck or 2.3 Foxcar are all there, once at a car yard, the little green, blue, white red and green components get prized off with a flat head screw driver, and then you pay extra for each one of the about 35 parts that make up the full emissions package. In fact, there are, by my reconing, 93 or so parts in any normal 1980 to 1986 1-bbl carb car.

Emissions engines use

1. more fuel,

2. make less power,

and

therefore,

3. naturally make more heat.

It's the ignition advance strategy, not EFI pulse-width or light off of the cats, that fixes the first four minutes of sub 65 deg F ambient and sub 190 deg F water operation.

All that smog crap doesn't help acceleration or power during cold start, BUT it does help cold start performance, but in terms of setting of the "inside state" warm up, cutting peak advance in high gear, and running less advance at the plus 35 mph area while warming up, really wipes off about a minute of warm up time. That was the main reason people hated early emissions gear, the cars woulds overheat....

Emissions Junk?

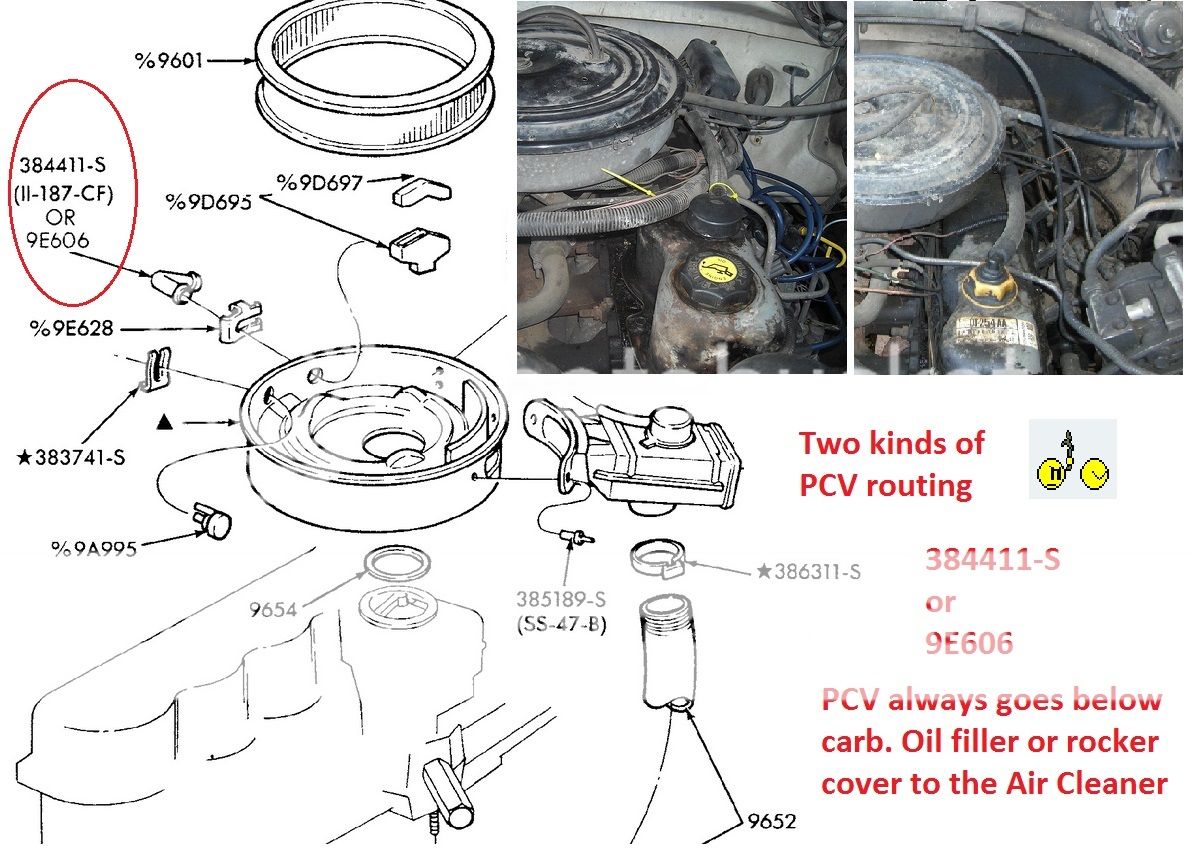

Before it was screwed with, your air cleaner was like this

Get the Fatory sys

GetthefactorySystem!

#13 by NumberDummy at 11-08-2014, 09:53 AM tried to list the PCV parts, but its for the Gomer Pyle hat, not the one you have....but it lists the parts

https://www.ford-trucks.com/forums/1341 ... ather.html

also, for everything, https://www.ford-trucks.com/forums/1139 ... ent-2.html

Inside, the other air cleaner has these parts.

ACL Bi Met in the top, two post type, probably same as 1982 -1983 3.8 Carb Essex V6 in the Fox body Fords.

Then the valve cover breather, now to the filler cap.

Yours won't have the green valve, it should have been born only the white item stamped TVS, I'm guessing.

White and Green Delay Valve to brown stripe BWD EC518 Vac Motor Assembly

2nd line down in this list

Get the Fatory sys

GetthefactorySystem!

#13 by NumberDummy at 11-08-2014, 09:53 AM tried to list the PCV parts, but its for the Gomer Pyle hat, not the one you have....but it lists the parts

https://www.ford-trucks.com/forums/1341 ... ather.html

also, for everything, https://www.ford-trucks.com/forums/1139 ... ent-2.html

Inside, the other air cleaner has these parts.

ACL Bi Met in the top, two post type, probably same as 1982 -1983 3.8 Carb Essex V6 in the Fox body Fords.

Then the valve cover breather, now to the filler cap.

Yours won't have the green valve, it should have been born only the white item stamped TVS, I'm guessing.

White and Green Delay Valve to brown stripe BWD EC518 Vac Motor Assembly

2nd line down in this list

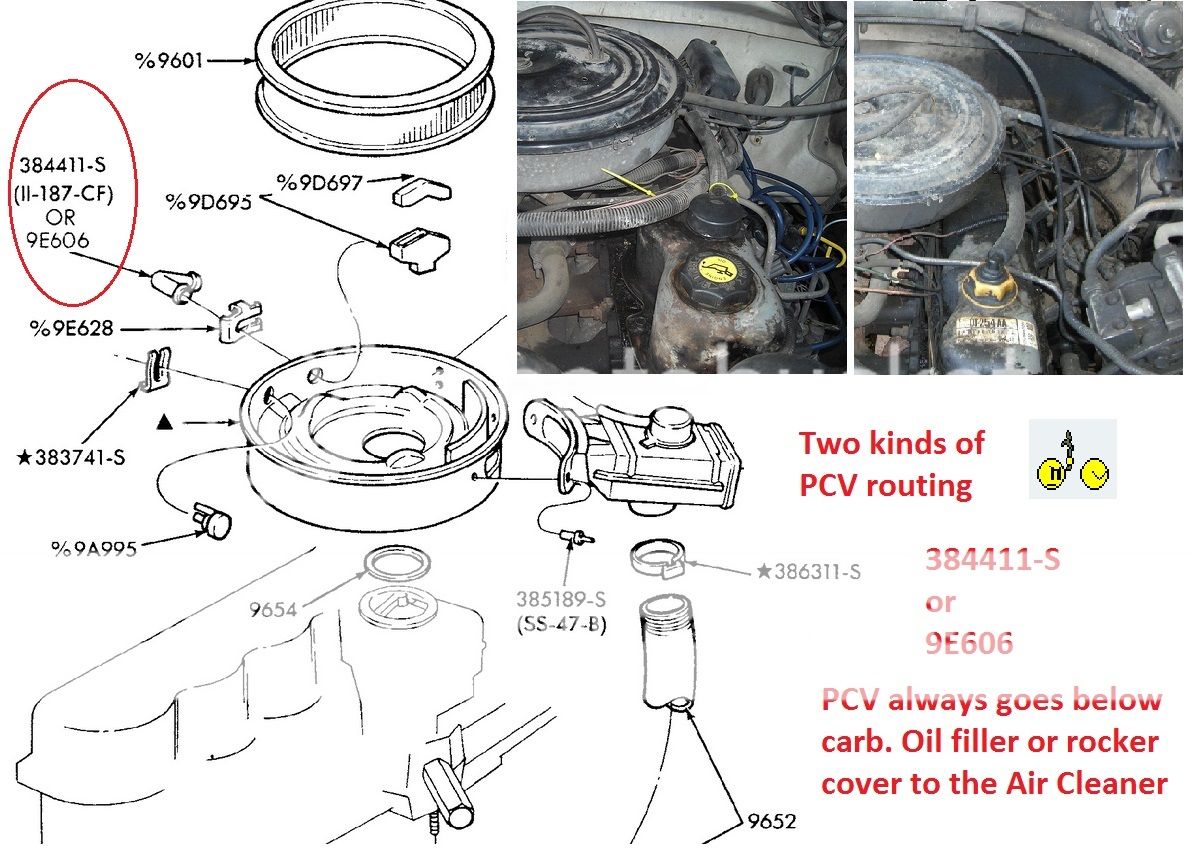

I'm trying to re-route the PCV valve to the air-cleaner using the filter that came with it. I know you're not supposed to get much vacuum from the PCV system, but I'm not seeing any. 0 in/Hg at any RPM.

It doesn't look like there's a grommet that goes with it, but there has to be something else I'm missing.

It doesn't look like there's a grommet that goes with it, but there has to be something else I'm missing.

Ford never liked to, but every year the VECI set ups changed. On the carb 4.9 liter 300 i6, Feedback carbs, or, on the 3.8 liter 231V6, going from 2-bbl carb to CFi, each new emission standard got a air cleaner new re-routing.

PCV to under the carb, rocker cover to air cleaner to "feed the machine". Don't work any other way.

Do it like this

:mrgreen:

:mrgreen:

PCV to under the carb, rocker cover to air cleaner to "feed the machine". Don't work any other way.

Do it like this

:mrgreen:

:mrgreen:

The last pic looks good, but seems backward?

The oil fill is at the back - harder to utilize (may B the a/c has to come off to add-a-qt?) but a nice short run to the a/c.

Where do the TWO lines frm the frnt PCV go? Another a/c location & a manifold nipp[le?

Mine is a '69 250 and not as complicated (yet).

Like to have a closed, filtered system...

The oil fill is at the back - harder to utilize (may B the a/c has to come off to add-a-qt?) but a nice short run to the a/c.

Where do the TWO lines frm the frnt PCV go? Another a/c location & a manifold nipp[le?

Mine is a '69 250 and not as complicated (yet).

Like to have a closed, filtered system...

Well, I'm dadgum tired of trying to adjust the accelerator pump by taking the top half off and fiddling with it only to find that I made it worse somehow. So, I picked up a spare carb that I'm going to mutilate so I don't have to remove the top to adjust it. Before I do this, any reason I should swap out this carb for the one I have on there now?

Click the pictures for big versions, long story short, 6554s and 75-1984, current carb is a 7115s and 75-2079

And yes, X, I do have a colortune on the way.

Click the pictures for big versions, long story short, 6554s and 75-1984, current carb is a 7115s and 75-2079

And yes, X, I do have a colortune on the way.

chad":5u9hbnvy said:The last pic looks good, but seems backward?

The oil fill is at the back - harder to utilize (may B the a/c has to come off to add-a-qt?) but a nice short run to the a/c.

Where do the TWO lines frm the frnt PCV go? Another a/c location & a manifold nipp[le?

Mine is a '69 250 and not as complicated (yet).

Like to have a closed, filtered system...

That's how all Granada onwards Factory 3.3's and 4.1's were arranged.

https://www.youtube.com/watch?v=H70V1xDGOMc

And all 3.3 Foxes

Stock......

Or modified.......

Asa":1tlh43z0 said:Well, I'm dadgum tired of trying to adjust the accelerator pump by taking the top half off and fiddling with it only to find that I made it worse somehow. So, I picked up a spare carb that I'm going to mutilate so I don't have to remove the top to adjust it. Before I do this, any reason I should swap out this carb for the one I have on there now?

Click the pictures for big versions, long story short, 6554s and 75-1984, current carb is a 7115s and 75-2079

And yes, X, I do have a colortune on the way.

A spare is good. A person really ought to make one change at a time. If it really is gallin' ya that much, you could do a two 1/8" drill hole modified top to adjust the accelertor pump, and seal it with some gromets. One hole to preload the pump arm, then another to turn the screw. If that's what you have to do to maintain sanity, all good, your call. The screw does have about 10 turns, and it raises the 2.625" long metering rod rod up and down in the jet as per Motzing and The Frenchtown Flyers discussions.

You'll have to make surethe PCV inflow is set up properly/correctly as a closed system before you can even start. pcv set up,

it is 45% of the idle, the ignition if properly set up, 35%, and the jetting, just 20%, since you can raise or lower the metring rod to compensate.

The standard metering rod taper is 50 thou, that is, the standard taper from the small to the large step is about .040 to .050" long depending on the jet size it was designed for.

The ignition has to be basline mapped and re-check and controlled, with both with vacuum hooked and vacuum unhooked (cr_bobcats post #7 » Fri Aug 15, 2014 ) readings taken....this way.

viewtopic.php?f=1&t=72349&p=555788#p555788

cr_bobcat":1tlh43z0 said:So I've finally gotten around to mapping the timing events of this new HEI style distributor. This morning I just measured with the vacuum can connected. Tomorrow morning I will measure with it disconnected and the hose plugged. I started at about 700 RPM as this was about as low as I could drop it and keep the engine running reliably.

RPM Timing

----------------

700 16

800 16

900 16

1000 16

1250 20

1500 25

1750 34

2000 39

2250 42

2500 45

2750 47

3000 50

I have an timing light with a built in tach and advance adjustment. Obviously all measurements here are approximate.

This seems a bit aggressive to me but obviously I don't know for sure what this profile should look like otherwise I wouldn't be here. I'm pretty sure my curve is off but that's based off of a gut feeling that I feel like there's more power to be had with my current setup. She just feels a little mushy. Am I right in my assumption here or are things looking ok? Do I need to take some more measurments with vacuum connected?

Pertinent info: idle currently set at 1000, Holley 1940 carb, stock exhaust, unknown cam (let's assume stock), C4, unknown rear-end (again, let's just assume stock)

I still plan to measure how much vacuum I have but haven't gotten that far yet. I've got a guage but I just haven't taken the time to do it. I should just do that tomorrow when I plan to disconnect the can and check to see how much mechanical advance I'm actually looking at.

My ancient $450 doller Sun Scope picks up all the ignition related faults, like crossfire and other faults, and air fuel ratio.

So your going to have to do it alone without that help.

Then adjust idle air fuel mixtures, and then find a way to define cruise and acceleration (wide open throttle) mixtures. Those last two are set by the metering rod and jet choices.

The baselines I gave you for jets are based on the jet to rod area from http://www.blackhawkengr.com/Black%20Ha ... ustom.html.

the "General Jet & Rod Table" http://www.blackhawkengr.com/General%20 ... Tables.pdf.

If you start with what was on the 7115s and 6554s with its basic jets, they will be very rich the way they came, the 75-1984 rod is way leaner as I guess its for a 240, and no doubt, will also have the 120-407 jet, the 107 thou one. With a 75-1984 rod and a 107 jet, it could work okay. TRY IT!.

It takes more time, but IMHO, the right way to go is lean, and then richen it off in steps by the main jet. So keep the 7115s metring rod, and adjust air fuel by 100 or 101 jet if you have to. Hopefully, what you have will work.

Recaping....from the graph....

Blue line is 10 up from the bottom, page 241. 75-2079, designed for a what may actually be a 240 with 107 jet. Exactly it for your 7115s.

#75-2175 or 75-2176 (Red lines underneath), are the normal limits for 70's 300 with 107 jet. Rich.

The 75-1984 rod is way leaner than your 75-2079, way too lean for a 98 jet, but might be okay with a 107 jet.

To repeat, the 75-2147, 101 and 75-1990, 101 jet, they will work well. Those metering rod/jets on 199-232 engines have a nice, lean cruise, a very rich idle, and a not very rich wide open throttle. They cope with PCV valves, they are tuned for them.

The rules are, if you can prove rich or lean by WOT plug readings, and idle by color tune, and mid range by loaded uphill 2nd gear 30-50 mph acceleration, you can then tailer the fuel curve.

So at the very most, you might want to look at either a 101 main jet later on if your mixtures with the PCV really are lean. Which I very much doubt.

Mike has a 75-1986, which, with your stock 98, richens the idle, and leans off the cruise, and keeps Wide Open throttle just the performance side of stoich.

See http://www.hotrod.com/articles/ctrp-040 ... rburetors/

The only issue with the Co curve for exhaust gas checking listed is that engines can run best in the leaner than 14.7:1 ratio to 16.1:1 ratio cruise and idle, and with a nice fat spark, modern testing equiment removes the ablity to do that.

That's because of the EPA and Federal Emission standards. You can go that lean if your fuel is well atmoised, and you've got a good exhaust system, and your enghine runs cool enough. Between 1978 to 1981, all non feedback YFA 4.9's were more economical than feedback carb 80's 4.9's with strict 14.7:1 readings. With oxygenated blends, those trucks are running 15.1:1 actually.

Asa":7j4t0m7r said:Well, I'm dadgum tired of trying to adjust the accelerator pump by taking the top half off and fiddling with it only to find that I made it worse somehow. So, I picked up a spare carb that I'm going to mutilate so I don't have to remove the top to adjust it. Before I do this, any reason I should swap out this carb for the one I have on there now?

Click the pictures for big versions, long story short, 6554s and 75-1984, current carb is a 7115s and 75-2079

And yes, X, I do have a colortune on the way.

Cool...I found a lot of other data.

https://www.ford-trucks.com/forums/1056 ... ation.html

Wrong info, but even a stopped clock is right twice a day!

The common 6300 YFA carb had a 75-1980 rod and a 101 thou jet.

Now 6300S, 6300SA, is an AMC Jeep 1973 232 or 258 1-bbl carb. Everyone says 101 main jet, confirmed.

So 75-1840, 75-2147, 75-1990 are AMC 232/258 batches as well as 199 .

So your 75-2079 and 75-1984 metering rods are indeed lean, and should also work fine with the 107 thou 120-407 jet if you want to.

I guess it was Fords intent to have fairly standard carbs between the 240 and 300.

I'm sure that 120-407 is the 240 standard jetting now. The leanest rods with the richest jet.

Recapping on all this...the YFA is simple, dead reliable if the rules are followed.

The rules are:

1. Any similar capacity, similar power OHV I6 will behave the same way.

2. Any 1-bbl carb is PCV sensitive, the YFA no different.

3. The factory ball sizes, check weights and metering rod settings for the carb number must be followed.

4. Chuck Riblett's BlackHawk blackhawkengr.com jet area and metering rod chart comparisons will give you exactly the right comparitive jet using the information from the 107 metering rods listed in Chart "YFA Carter Ford 200_240_250_300_rods"

http://i1215.photobucket.com/albums/cc5 ... 0_rods.jpg

and grumpy's garage.

http://garage.grumpysperformance.com/in ... carb.1820/

All the Metering Rod engineers do the jet and metering rod tables this way. Q Jet, Thermoquad, Carter etc.

https://www.ford-trucks.com/forums/1056 ... ation.html

Wrong info, but even a stopped clock is right twice a day!

The common 6300 YFA carb had a 75-1980 rod and a 101 thou jet.

Now 6300S, 6300SA, is an AMC Jeep 1973 232 or 258 1-bbl carb. Everyone says 101 main jet, confirmed.

So 75-1840, 75-2147, 75-1990 are AMC 232/258 batches as well as 199 .

So your 75-2079 and 75-1984 metering rods are indeed lean, and should also work fine with the 107 thou 120-407 jet if you want to.

I guess it was Fords intent to have fairly standard carbs between the 240 and 300.

I'm sure that 120-407 is the 240 standard jetting now. The leanest rods with the richest jet.

Recapping on all this...the YFA is simple, dead reliable if the rules are followed.

The rules are:

1. Any similar capacity, similar power OHV I6 will behave the same way.

2. Any 1-bbl carb is PCV sensitive, the YFA no different.

3. The factory ball sizes, check weights and metering rod settings for the carb number must be followed.

4. Chuck Riblett's BlackHawk blackhawkengr.com jet area and metering rod chart comparisons will give you exactly the right comparitive jet using the information from the 107 metering rods listed in Chart "YFA Carter Ford 200_240_250_300_rods"

http://i1215.photobucket.com/albums/cc5 ... 0_rods.jpg

and grumpy's garage.

http://garage.grumpysperformance.com/in ... carb.1820/

All the Metering Rod engineers do the jet and metering rod tables this way. Q Jet, Thermoquad, Carter etc.