Tune it.

The 1946 Holley and YFA Carter were swapped between the 200 and 250 in the 1977/1978 Mavericks and 1975-1980 Granadas.

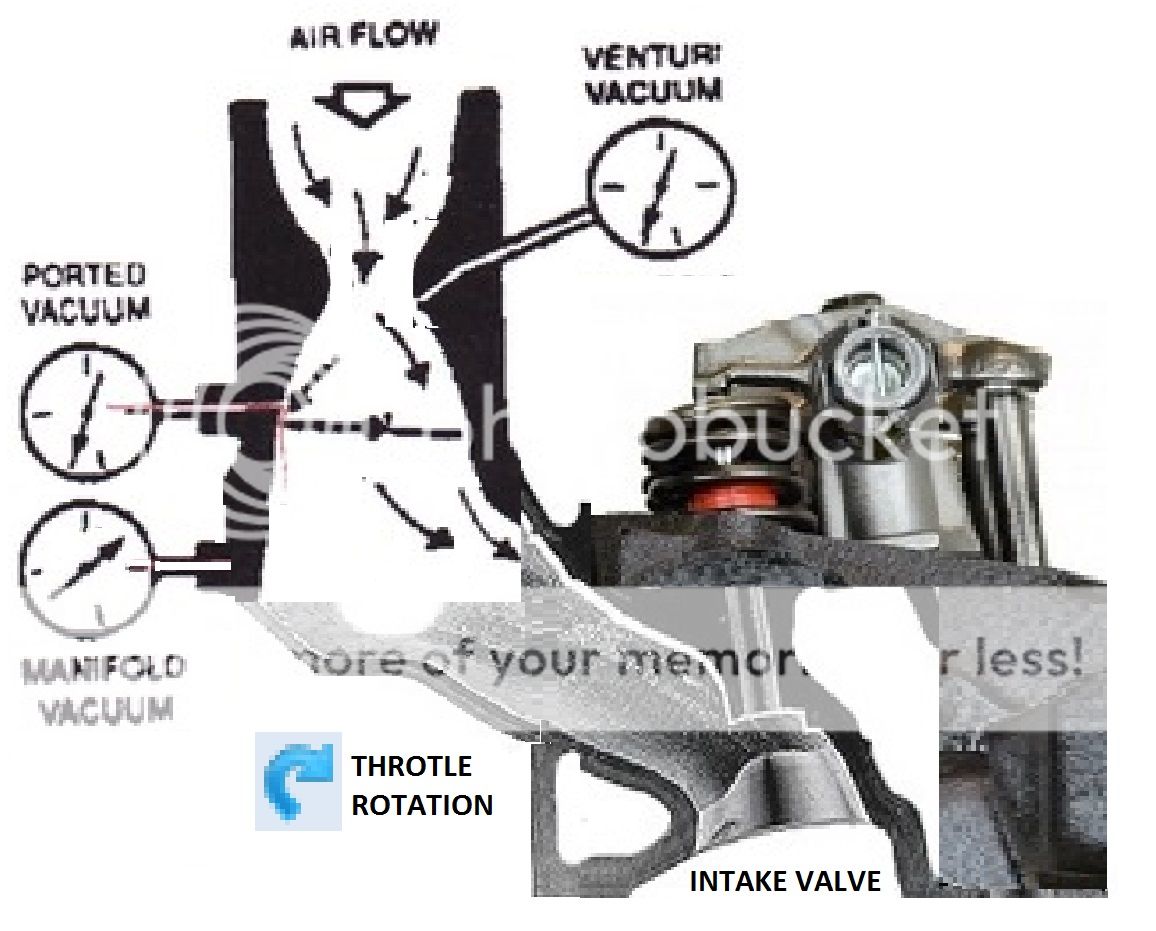

Each of those two 1-bbls had a 1.3125" venturi. Along with other modifications, the 1966 240 Big Six 1.29" venturi Autolite 1101 carb Ak Miller used in his 1967 Hopped up Horse Mustang took rear wheel horspower from 65 to over 100 hp. Every good hp engine had the bigger venturi carb.

Personally, based on the figures, the bigger 1-bbl Ford carbs are more hp. Swapping carbs is not the first thing to do if the one that is there is good enough.

65 rwhp is 82 hp flywheel net hp,

100 or 105 rwhp is 126 to 133 flywheel net hp. In net hp increase at the flywheel, thats 44 to 51 hp.

http://www.allfordmustangs.com/forums/a ... page-4.pdf

"Horsing Around With The Mustang Six"

This article is a reprint from Hot Rod Magazine by Ak Miller from a 1968 Ford Tech bulletin (Thanks Doug!)

http://www.cometcentral.com/tech/hm6/index.html

"Horsing Around With The Mustang Six Part II"

This article is a reprint from Hot Rod Magazine by Ak Miller Part 2 of the above article

http://www.cometcentral.com/tech/h2/index.html

The relatively straightforward and inexpensive modifications up to this point added 35 (rear wheel) horsepower to the Mustang six banger. Ak got still another 25 horsepower with additional modifications, some of which were not so common

I've never had any problems with any of Fords emissions era 3.3's...they were fully debugged by 1980 to 1983.

Its a dark ages, medieval ignorance that previals, in opposition to the published facts, and numerouss stoshes on the internet don't alter the facts.

No other book is as usefull as The Falcon 6 Performance Handbook. Even though it has a 1976 to 1983 frontal labotomy.

CZLN6":3sl5nv2n said:

To All interested:

X has been making a case for the Late model Holley #1946. We have mentioned it the handbook but have not recommended it for several reasons. They are that the 1946 requires a few to many links to vacuum switches and thermal switches and other links to function properly. Most moders want something that can be bolted on an go. The 1946 is not user friendly to the shade tree tuner. That is why we keep our recommends to early Holleys, Autolites and Carter YFs and RBS.

IF you are capable of navigating the labyrinth of support structures for a 1946, like X is, have at it.

Hey Kissangle, have we scared you away? Overwhelmed you? Let us know how you are doing.

Adios, David

The Home page shows that the advice and details drops off at the 1976 to 1983 era. The book would have to be another 100 pages longer to get those systems nailed.

There is no 1976 to 1983 info on 3.3 and 4.1 sixes.

http://www.falcon6handbook.com/facts.html

All the net readings from 1972 o 1976 were down on the 1978 to 1983 3.3 engines.

The 1976 to 1983 info you need is this. The evidence is in Fords EPA mandadted power and torque figures.

Increased torque at lower rpm, and higher compression, and power was 3 times out 4 times better than the 72-76 3.3, with 1972's 3.3 T code the only exception.

xctasy":3sl5nv2n said:

hotroady":3sl5nv2n said:

"As for the exhaust, I am skeptical of the benefits of X's adaptation of the cat exhaust manifold. I'm curious if anyone has ever done it and more curious about how well it worked"

I agree with David. The X cat may be a handy place to mount a turbo, but would kill bottom end torque for street driven 200. 41/4 in outlet would allow more volume of gas, but it slows the exiting velocity of the exhaust gas. I'd use 68 exhaust manifold, or go to a tuned header.

Be sceptical, that is

always good. But up to 9.5 extra horsepower and 6 lb-ft extra torque of evidence

is evidence enough.

The header is 4-1/4", but not fully into the exhaust header pipe; its annular area is just cousioned boundary layer, so its very efficent. Probably why the torque peak magnitude is rasied, and the peak rpm sometimes dropped. Its torque and power is improved throughout the rev range, even with the cam channge they made.

Mistake ridden, there could be 12.5 hp and 7 lb-ft extra if anyone is silly enough not to crosscheck the 4speed SROD Mercury Capri 3.3 RS Hatch article on page 64 to 66 in Motor Trend March 1981.

I'm sure it did a 19.08 second quarter mile at 71 mph and a 90 mph top speed. I had my 1981 Hatch to 95 mph with ease. On that car with a 0.46 drag factor, 20.8 sq ft frontal area, and 190 section tires, that acceleration rate and terminal trap speed speed requires 87 hp at least to move a 2640 pound car with two testers and a full tank of gas, and only 67 hp to make 90 mph, and 78 to make 95 mph and just 90 flywheel hp to make 100 mph.

Feed in 3055 pounds and 87hp into the

http://www.wallaceracing.com/et-hp-mph.php program.

is 19.07 seconds and MPH of 70.86 MPH.

If we accept that the 97.5 hp at 4000 and 161 lb-ft 1400 rpm is Jim MacQueen's eye sight error while perhaps proof reading under a Helmick Covered Bridge ,

( along with the Holley VV 2-bbl carb -it was a Holley 1-bbl 1946C

and a Ford mistake, the 2.49 final drive ratio -it was a 3.08:1 axle with 0.81 overdrive 4th on the last SROD's before the T4 got subbed in later in 1981 with the 2.47 axle)

in this March 1981 Motor Trend article

http://www.ascmclarencoupe.com/Literatu ... 1981_2.jpg

then the real Detalis were ex SAE and from

http://vb.foureyedpride.com/showthread. ... comparison

Info depends on where you look. The Mustang site mustangattitude.com for T and B codes.

Has 87HP for 1982

http://mustangattitude.com/cgi-bin/...show=All&view=engine&optn=B-code&comm=&page=1

, and 94 hp for 1981

http://mustangattitude.com/mustang/engine_allhp.shtml

http://www.foxtbirdcougarforums.com/showthread.php?32233-Ford-Fox-Engine-Reference-Guide

The engine code is the 5th digit of the VIN on pre-81 models

The engine code is the 8th digit of the VIN on 81-up models

1979-79 Mustang

200 CI (3.3L) 1bbl I6

Vin code: T

compression: 8.5:1

horsepower: 85hp @ 3600rpm

torque: 154 lbs-ft @ 1600rpm

Availability: 1978-79

1980-88 Cougar

200 CI (3.3L) 1bbl I6

Vin code: B, T

compression: 8.6:1

horsepower: 91hp @ 3800rpm

torque: 160 lbs-ft @ 1600rpm

Availability: 1980-82

1981-82 Granada

200 CI (3.3L) 1bbl I6

Vin code: B, T

compression: 8.5:1

horsepower: 88hp @ 3800rpm

torque: 154 lbs-ft @ 1400rpm

Availability: 1981-82

1983-86 LTD

200 CI (3.3L) 1bbl I6

Vin code: X

compression: 8.5:1

horsepower: 92hp @ 3800rpm

torque: 156 lbs-ft @ 1400rpm

Availability: 1983

1983-86 Marquis

200 CI (3.3L) 1bbl I6

Vin code: X

compression: 8.5:1

horsepower: 92hp @ 3800rpm

torque: 156 lbs-ft @ 1400rpm

Availability: 1983

94.5 hp was the rated amount for a 1980 B-code manual, but it varied from 87 to 94.5 nominal 1980 thru to 1983, with any number of ratings between 87 and 94.5.

Torque was the same or up to 6 lb-ft more, at less rpm, depending on year.

In addition, Ford at some stage had to detox the engine for manual gearboxes, while some areas didn't have that option. Even when Ford retarded and played with the camshaft, the result was still more power and more torque with this exhaust in an era where there was now a mandatory air pump, and secondary AIR in CA models. The 1980 B code model had 9.5 hp extra over the 1979. Then it varied according to other changes in 1981, 1982, and 1983, but always more than 85 hp by 3 to 7 hospower. Rated torque was often up despite the variances.

Those 93 extra systems are listed here....took me 5 years to complie that from about Seven other Ford Fox, Truck In line Six and Ford Service Technician experts

viewtopic.php?f=1&t=75674&p=591463#p591463

Post #11 by xctasy » Mon Jun 12, 2017

To the late Dennis Hot 6t Falcon and his brother David CZLN6

This is the all encompassing Thermactor/ IMCO and pre Port EFI list formed from 5 years work on the photo's and descriptions from consultation with four other websites, and a lot of very good, very helpfull people. For our EFI Big Six guys, these terms help, although they don't include TFi, PIP, SPOUT, and the details which most owners have quickly learned from the modern Injection world, and its much easier than the 1978 to 1983 3.3 small six and 1978 to 1980 4.1 small six era.

That's because

A. no one understands the 1976 to 1983 emissions parts.

B. There is an evil, ill thinkin' Dumb A$$ campaign to rip off the 13 to 93 parts that consitute the 1976 to 1983 US EPA and Federal Emissions gear, and

C. the truth is, any removal of anything won't liberate one hp. Not one. An engine is a combination of matching parts.

The reason the 1976 to 1983 engines made 85 to 94.5 hp was

1. Cam Lift,

2. Valve lift,

3. Cylinder head air flow at the valve (it doesn't hurt power if the cam is optimized, but added air flow generally adds power, although there are expections).

The engine fell flat at 3500 rpm because you've got six pistons being fed through one 1-11/16" (1.6875") log intake.

Other in service factors then degreade the orginal 85 hp.

4. Fuel system delivery via a clean system with good clean fuel tank and pickup, good fuel pump, and clean fuel lines is required to be up to spec.

Static Pressure: 5 to 7 psi

Volume: Minimum 0.23 liters (1 pint) in 20 seconds

Eccentric total lift: 0.290-0.310 inches

Some of the sending units have filter socks on their sumps, they clog. The threads on the carb at the filter are known to strip and leak with constant loosening and tightening

Murky Fuel lines and tanks, tank and line varnish and vac lines that aren't vac lines anymore, hardened or blocked to distibutor fittings

5. Exhaust flow (the backpressure must be measured with a 1/8" BSP fuel pressure gauge, and must be less than 4 psi at 4500 rpm)

You do that by braising in 1/8" fuel pressure fitting in the exhaust by oxy acetaline. Or a narrow or wide band HEGO sensor with the same size as a spark plug, and get an adaptor and check it for backpressue the same time.

and

6. tailoring the Ignition advance curve (checked against stock specs, with the hookups as per the 1976 to 1983 Emissions tuning label), but mapped and checked.

wsa111 is a good contact on this bord to have it revamped

viewtopic.php?f=34&t=76480&p=588846#p588846 )

You need to list the following mapped out like

1bad6t did

As FalconSixDelivery from this company said

its nice to have a grocery list, but unless its calibrated and tested with the right vac arrangement for your planned application...., your just guessing....

viewtopic.php?f=1&t=72349&p=555788#p555788

cr_bobcat":3sl5nv2n said:

So I've finally gotten around to mapping the timing events of this .....distributor. This morning I just measured with the vacuum can connected. Tomorrow morning I will measure with it disconnected and the hose plugged. I started at about 700 RPM as this was about as low as I could drop it and keep the engine running reliably.

RPM Timing

----------------

700 16

800 16

900 16

1000 16

1250 20

1500 25

1750 34

2000 39

2250 42

2500 45

2750 47

3000 50

I have an timing light with a built in tach and advance adjustment. Obviously all measurements here are approximate.

This seems a bit aggressive to me but obviously I don't know for sure what this profile should look like otherwise I wouldn't be here. I'm pretty sure my curve is off but that's based off of a gut feeling that I feel like there's more power to be had with my current setup. She just feels a little mushy. Am I right in my assumption here or are things looking ok? Do I need to take some more measurments with vacuum connected?

Pertinent info: idle currently set at 1000, Holley 1940 carb, stock exhaust, unknown cam (let's assume stock), C4, unknown rear-end (again, let's just assume stock)

I still plan to measure how much vacuum I have but haven't gotten that far yet. I've got a guage but I just haven't taken the time to do it. I should just do that tomorrow when I plan to disconnect the can and check to see how much mechanical advance I'm actually looking at.

7. The stock single row timing chain is loose, and is retarding the cam postion and influencing spark scatter. The cam lobes won't even be making 370 thou lift, and might be worn, and the lifter preload, if not set right, will be loosing hp.

On a 1963 pre -emissions 200, or a 1983 3.3, the out of spec exhaust, ignition and cam timing have the same result...power loss.

The 1-bbl Holley 1946 and YFA Carter were Fords weapons of choice for the Fox and F 150, respectively.

Fox 3.3 made 85 hp in 1978, then 91 hp in 1980, then dropped back to 87 hp till 1983. It was quoted as 94.5 hp in some other write ups. The old 120, 115 and 110 hp gross ratings were about 82 hp net, so the 1978 to 1983 3.3's were 12.5 hp more powerfull than the 1963 to 1977 200's.

F150 made 114 to 123 hp from 1972 to 1986, with a carb the same size as the Holley 1946...they are interchangable, and the Holley jetted 1946 makes more power than the YFA if you swap the 61 jet out for a bigger jet.

The reason it made 85, 87 and 91 hp was the cam lift, the stock cam has 256° duration. 0.368" lift and 28° overlap."

Lets compare the other Maliase Era 1978 to 1983 V6's and overseas in line Six Falcon engines.

The 1979 and later 1983 2.8 2-BBL V6 made 18 to 23 hp more than the 3.3 (

109 and then 114 hp), easily enough to bring back the power balance in favour of a proper 3.3. It was withdrawn between 1980 and 1982, then came back for the Ranger, Bronco II and Aerostar Van with another 5 hp.

In Australia that year, 1981, a 3.3 liter engine made

114 hp, the cam was the same duration as the US 3.3, the carb a 1-bbl and it had a more restrictive exhaust.

The Aussie 3.3 made more power by

1. extra cam lift via 1.73:1 rockers and

2. 145 cfm of intake flow at 435 thou vlave lift in the head, and

3. a detonation reistant 9.15:1 compression head on 97 octane gas.

The 79-83 V6 made the extra power via

1. 276 degree cam duration and

2. a V8 spec 1.14 " 2-BBL carburator.

It did that with less than a 8.7:1 compression ratio, 87 octane gas.

Its heads flowed 110 cfm at 400 thou lift, about the same as the 3.3 D8 and E0/E1 heads. So it had a lot of ability to rev from 3500 to 5800 rpm, but it was the cam and carb that made the extra 18-23 hp, not the cylinder head flow or any compression bump up.

Emission control only required a lower compression ratio to meet the 50000 mile durablity test, and avoid breaking the cast iron con rods.

Adding 1 ratio of compression gives you 3 extra horspower.

http://www.bgsoflex.com/crchange.html":3sl5nv2n said:

Bowling's Compression Ratio -> HP Calculator

Computation Results:

Engine Horsepower (peak) is 85

Old Compression Ratio is 8.35

New Compression Ratio is 9.35

Computation Results:

Computed New Engine HP is 88, a 3 percent change

So how do you close the difference between the 109 and 114 hp engines verses the US 3.3, and make more torque?

Cam lift, valve lift, clean up of the valve pockets and backcutting the intakes, a bigger jet, and in your case, understanding how the Air Fuel ratio works

Best advice?

Wide band O2 sensors which give you air fuel ratios are just fine if you have the time and money, but auto engineers went to CO2 readings many years ago to simplify it, and the black CO to AIR fuel ratio in terchange is the easiest system to tune a jet to if the cars under load.

These are the is the graphs...

Toyotas later graph

Black line for CO on the right axis

Crytons graph is the blue line for CO

At 15.1 to 13:1, CO % via the sniffer test is VERY accurate as it drops like a fly in the frost....

Soooo

You could jet up from the stock 61 1946 Holley jet, check your fuel air under 25 mph load at an I/M test station, and stop up jetting when you get to a % CO under load of about 2%, which is a about 13.8 parts or air to one of fuel. 14.7 or 15.1 (..75 to 0.60% CO) is too lean under load for our cars. 4.5 to 5% CO is ideal wide open throttle 12.5:1 one.

This is how we tuned our old propane vehciles in the 80'S for safety, although that was done by allen key and screw, not jet change

Modern ways aren't always the easiest. Every garage has access to tuning gear, rather than pay for individual equipment, you use the I/.M stuff

Right Now.

Right Now.