You can, but it doesn't ever work well enough to create a reliable low vacuum curve. They are very slow to provide advance when the engine is accelerated under load. Where the centrifugal weights of a conventional distributor immediatly swing out as the rpm is increased, the vacuum diaphragm in the LoadoMatic reacts

slowly to the weak signal that is applied to it from the carburetor's Spark Control Valve (SCV)

It's unreliable, and when it needs a lot of initial advance fast for economy, or torque and power during acceleration, it drops the ball. Every time. The result is a loss of low end pulling power and then, a loss of speed to do any task (ie, a loss of power).

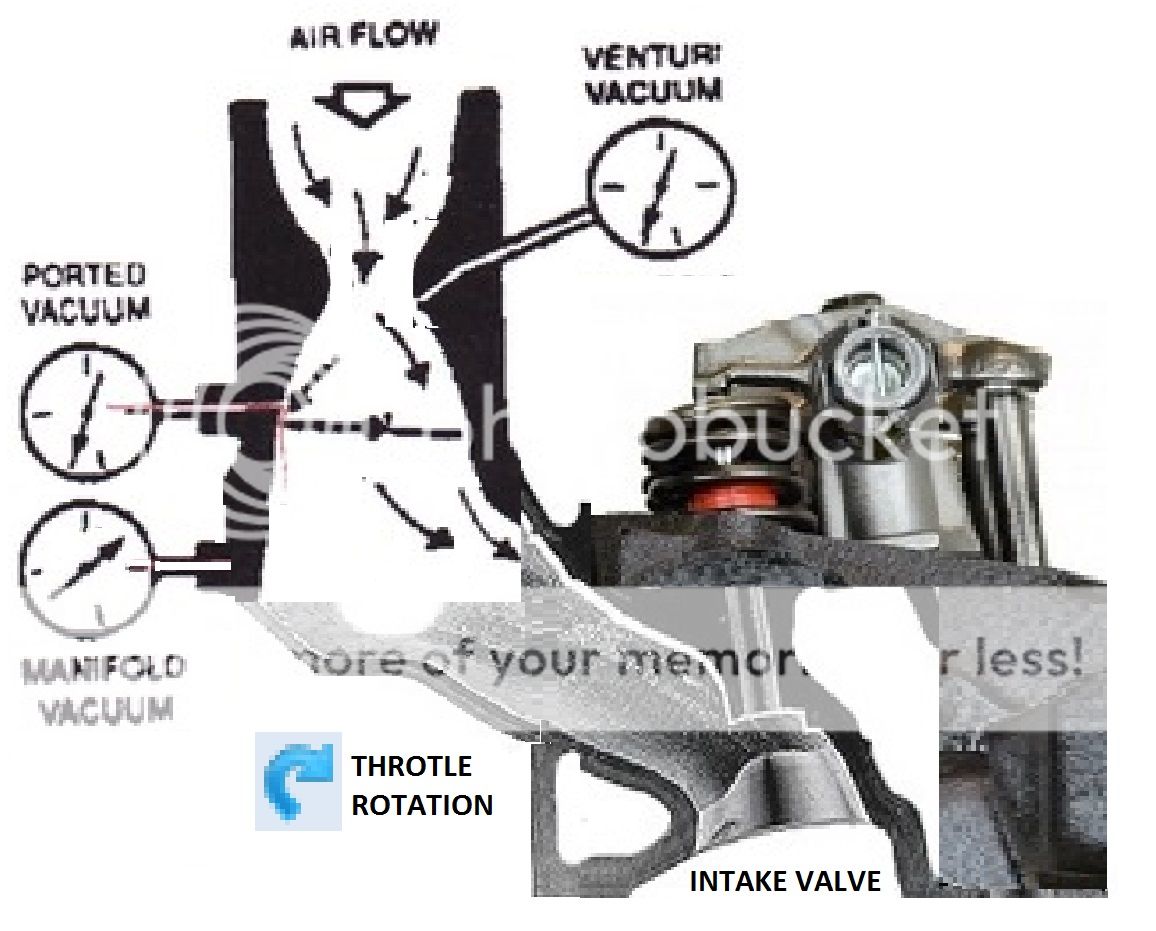

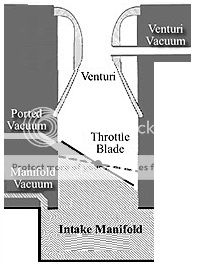

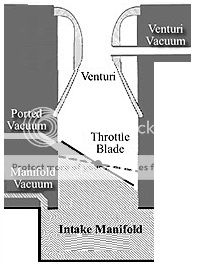

Potentially, there are three vacuum sources ultimately on any carb.

Loadomatic port has two drillings inside, one to the venturi (Velocity/Speed based Spark vacuum SCV port) )and then one down into base area (MANIFOLD VACUUM).

It outputs to the distributor an interplay vacuum between manifold and speed venturi vacuum. The quirky reverse Power Valve funtions as a when the vacuum drops, the valve starts to shut. It was designed not to hurt the vacuum window wipers, and the transfer port (T) is too small, and zig zags over a labyrinth which cannot allow the volume of air needed to calibrate it for a proper performance engine.

There is a T channel on top, above the T port (Transfer Port).

Fords rationale was that side valve 135's, 221s, 239's or 337's, all 239-312 Y blocks and log head 144/170/200 sixes were basically just low rpm sluggers, and Loadomatic works fine with that scenario. Great with vacuum wipers too. But any time you carb, cam or exhaust it up, it cannot cope at all.

Plug the outer SCV port and you can forget about it without further work. This will not affect carburetor operation. It'll still suffer, and loose torque, power and will ping.

You'll never make a Loadomatic work the way a normal vac advance distributor like the California 1966-1968 Autolite or 1974 to 1983 Duraspark does.

http://m571.com/yblock/loadomatic.htm

How does a Load O Matic Distributor Work?":1sobc8q5 said:

As the engine rpm increases, the vacuum signal of the venturi will be passed across the top of the "T" channel to the distributor. Generally, this vacuum signal will be from 0 to about 6" of vacuum, and this will provide from 11* to 17* of advance AT THE DISTRIBUTOR. (Remember, you have to double distributor degrees for crank degrees.)

The exact amounts of vacuum and advance degrees will vary between engine applications, but this will get you in the ballpark.

When the manifold vacuum rises above 6" or 7", the spark control valve will open. At this point, the vacuum that is in the manifold will be applied to the top "T" channel from the spark control valve chamber. It MUST be at or above the vacuum level that is needed to open the spark control valve, so it is more than will be coming from the venturi signal at any RPM.

Therefore, at the opening point of the spark control valve, the signal that is applied to the distributor to control the advance will pass from the venturi signal to the manifold signal.

Putting this in terms of the engine, when the engine revs up, the advance is increased because the venturi vacuum is increased. So, advance increases as the speed of the engine increases.

But, if the engine load is light, the engine needs even more advance for better fuel economy (read the first part of the Load O Matic description to understand why). When the manifold vacuum gets high enough, the spark control valve opens and control of distributor advance passes to the stronger manifold vacuum signal, for even more advance.

If you've followed my attempt at explaining the Load O Matic to this point, you are probably thinking to yourself: "This can't be right, because the manifold vacuum will bleed out thru the orifice going to the venturi, instead of operating the distributor advance canister. Tthis doesn't happen, but if you have thought this, you have come upon the reason that the Load O Matic gives lousy performance:

The reason that manifold vacuum doesn't bleed off into the venturi is because the venturi orifice is very small. This restriction keeps the greatest part of the vacuum signal applied to the distributor advance unit, even though a slight amount of bleed off does occur.

But, in order to limit the bleed off, the venturi orifice is too small to allow enough air to move in the "T" cross passage quickly. So, an abrupt change in rpm will increase the vacuum in the venturi, but the orifice restriction in the distributor passage (needed to keep the manifold vacuum signal from bleeding off) will not pass very much air from the distributor vacuum canister, which keeps the Load O Matic from giving advance to the engine as quickly as it needs it.

The result is that soggy acceleration that Load O Matics are noted (notorious?) for.

viewtopic.php?f=99&t=76821

wsa111":1sobc8q5 said:

Read this link I put in our tech forum.

viewtopic.php?f=99&t=76821

This converts the loadamatic to ported vacuum. It eliminates the venturi vacuum from the DS11.

I can modify yours for $50.00. Bill