As for the 4 main 200’s they were made during the mid year of the 1963 year models. This was also around the USA special roll out of the 1963 1/2 Ford models that were built as part of Ford's, “Total Performance Program", this was in about February 1963.

These 200 4 main engines are ID'd as a T code in the Vin number. These first 200’s to the best of my knowledge were mostly only installed in the Ford Fairlane's or Mercury Medior's in the special 1963 1/2 year Models Ford rolled out here in the USA. But it's also possible a few would of also been installed in some of the Higher Trim Level 1963 1/2 Falcons and Comets IE like a Futura or S22's. They were also used throughout the 1964 model year production of those Falcons and Comets until the end of the 1964 Models I have also seen some recent examples of these Falcons. They have a Block Design Number of C4DE-6015-A

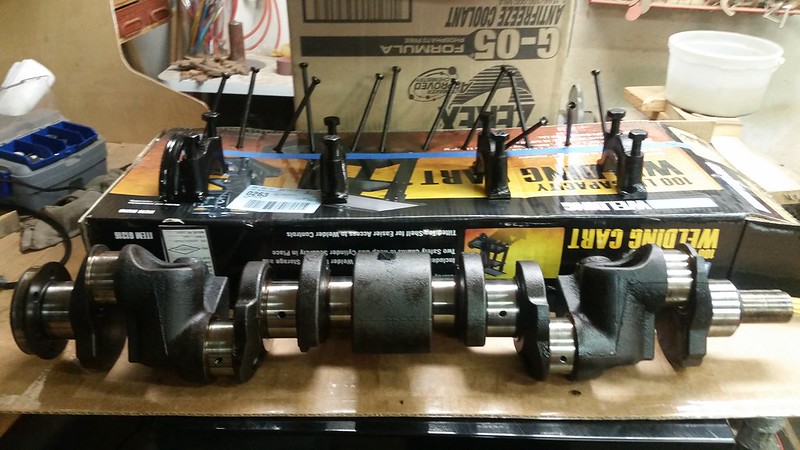

Basically these early 200’s were a only a short 1 & 1/2 year run before Ford started building the improved 7 main 200 blocks for use in the new 1965 Year Models such as the 1964 1/2 Mustang models (that were early production of the 1965's), happening about in February 1964. Externally the 4 main 200’s are not that hard to distinguish from a 170 engine, one sure way though is that like all the other 200 Six's they will also have 5 Freeze Plugs on the their exhaust side of the block. Another way for all of the 1960 to 1965 Ford and Mercury Small Six's though this may not be as as accurate is by their Valve Cover and Air Cleaner Paint Color that is only if they were apart for a rebuild or were repainted in a different Color. Edited

thank you gb500 for those pictures of the early 200 4 main block showing much of its details, like the 5 freeze plugs that sure clears up some of their mystery!

thank you gb500 for those pictures of the early 200 4 main block showing much of its details, like the 5 freeze plugs that sure clears up some of their mystery!