62Ranchero200

Famous Member

Greetings Ford Six Fans,

Background: '62 Ranchero, '74 250, early 300 forged rods, custom forged pistons, CI aluminum head with 55 cc chambers, Clay Smith 274/274/108 hydraulic cam, 1.6:1 adjustable rockers, Holley "500 CFM" 2-V carb with custom Quick Fuel metering block, CI headers, true duals with FlowMaster Series 10's, DS II with custom mechanical advance, MSD 6-AL, E-core coil, T-5, 8" 3.80 Trac Loc.

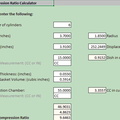

Over the holiday break I plan to warm up the 250 a bit - have a Clay Smith 280/280/108 hydraulic cam (the largest hydraulic cam Clay Smith makes for the small six) and a Holley 4-V carb I want to try. Am also considering milling the head to raise compression. Currently, the 250 is at .005 deck height, the pistons have a 15 cc dish, SCR has been estimated at 9.5:1 and DCR at a bit below 8:1.

The 250 build was five years ago, and the Ranchero has been driven 9,000 miles since then. This weekend I ran a compression test on the 250: cold, but all spark plugs out and throttle wide open. The results were:

1 - 160 psi

2 - 170

3 - 170

4 - 170

5 - 165

6 - 165

It looks like the outboard cylinder rings are wearing a bit more than the inboard cylinders, probably due to leaner mixture and/or higher temps on the outboard cylinders. Note: I checked the valve train and adjusted the valves just before this, so I know that all of the rocker arms are undamaged, all of the pushrods are straight, and oil is getting all the way to #1 rocker arm. The engine has never been overheated, run with low oil pressure, or overrevved (the MSD 6-AL has a built-in rev limited, set at 5,500 RPM).

In my area (Houston, TX), 92 octane is widely available and 93 octane is occasionally available (Exxon gas stations only, as far as I know).

Would it be safe to mill the head while it is off for the cam swap? Enough to raise the compression half a point? A whole point? I have been told that the aluminum head allows slightly higher CRs than an iron head would.

Thanks,

Bob the Builder

Background: '62 Ranchero, '74 250, early 300 forged rods, custom forged pistons, CI aluminum head with 55 cc chambers, Clay Smith 274/274/108 hydraulic cam, 1.6:1 adjustable rockers, Holley "500 CFM" 2-V carb with custom Quick Fuel metering block, CI headers, true duals with FlowMaster Series 10's, DS II with custom mechanical advance, MSD 6-AL, E-core coil, T-5, 8" 3.80 Trac Loc.

Over the holiday break I plan to warm up the 250 a bit - have a Clay Smith 280/280/108 hydraulic cam (the largest hydraulic cam Clay Smith makes for the small six) and a Holley 4-V carb I want to try. Am also considering milling the head to raise compression. Currently, the 250 is at .005 deck height, the pistons have a 15 cc dish, SCR has been estimated at 9.5:1 and DCR at a bit below 8:1.

The 250 build was five years ago, and the Ranchero has been driven 9,000 miles since then. This weekend I ran a compression test on the 250: cold, but all spark plugs out and throttle wide open. The results were:

1 - 160 psi

2 - 170

3 - 170

4 - 170

5 - 165

6 - 165

It looks like the outboard cylinder rings are wearing a bit more than the inboard cylinders, probably due to leaner mixture and/or higher temps on the outboard cylinders. Note: I checked the valve train and adjusted the valves just before this, so I know that all of the rocker arms are undamaged, all of the pushrods are straight, and oil is getting all the way to #1 rocker arm. The engine has never been overheated, run with low oil pressure, or overrevved (the MSD 6-AL has a built-in rev limited, set at 5,500 RPM).

In my area (Houston, TX), 92 octane is widely available and 93 octane is occasionally available (Exxon gas stations only, as far as I know).

Would it be safe to mill the head while it is off for the cam swap? Enough to raise the compression half a point? A whole point? I have been told that the aluminum head allows slightly higher CRs than an iron head would.

Thanks,

Bob the Builder

Edited with some additional info.

Edited with some additional info.