62Ranchero200

Famous Member

Greetings Ford Six Fans,

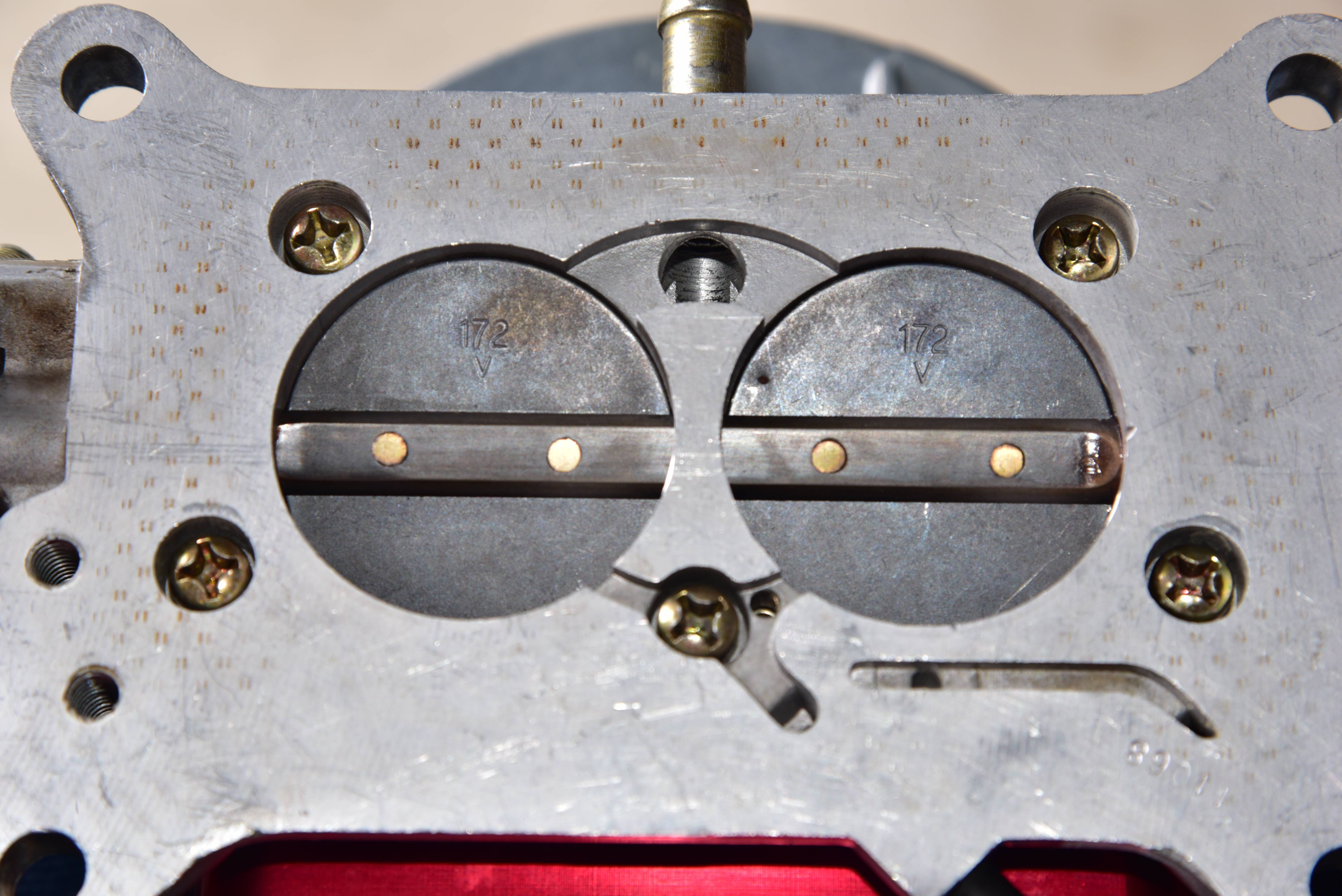

My COVID-19 project is a cam upgrade (from a Clay Smith 274H to a Clay Smith 280H, their largest hydraulic cam), milling the aluminum cylinder head for more compression, mild porting, and possibly carburetion upgrades.

Had the chance to visit the head today at the machine shop and discovered the following:

I CC'd the cylinder head at 55 cc; the machine shop found the same. My goal was to mill the head down to a 47 cc chamber for one additional point of compression; the machine shop milled .056 off of the head to get to the 47 cc chamber.

The intake valves were lapped; lapping was not sufficient for the exhaust valves because the values are apparently not perfectly concentric with the seats, so the valves/seats were reground.

Some mild porting was done, mostly removing small "steps" that existed around the valve seats.

My new Clay Smith 280H cam will have .512 lift with my 1.6:1 rockers; according to the machine shop, the springs will take up to .600 lift before coil bind, but I found out today that maximum lift before the retainer hits the valve seal is about .525. So, the machine shop is removing about .100 from the valve guides. This should open up the future possibility of .550-.575 lift, although the single springs may not handle that much lift correctly (I don't currently have any plans to go beyond the 280H cam).

The valve guides should be cut and I should be able to pick up the head early next week.

Thanks

Bob

My COVID-19 project is a cam upgrade (from a Clay Smith 274H to a Clay Smith 280H, their largest hydraulic cam), milling the aluminum cylinder head for more compression, mild porting, and possibly carburetion upgrades.

Had the chance to visit the head today at the machine shop and discovered the following:

I CC'd the cylinder head at 55 cc; the machine shop found the same. My goal was to mill the head down to a 47 cc chamber for one additional point of compression; the machine shop milled .056 off of the head to get to the 47 cc chamber.

The intake valves were lapped; lapping was not sufficient for the exhaust valves because the values are apparently not perfectly concentric with the seats, so the valves/seats were reground.

Some mild porting was done, mostly removing small "steps" that existed around the valve seats.

My new Clay Smith 280H cam will have .512 lift with my 1.6:1 rockers; according to the machine shop, the springs will take up to .600 lift before coil bind, but I found out today that maximum lift before the retainer hits the valve seal is about .525. So, the machine shop is removing about .100 from the valve guides. This should open up the future possibility of .550-.575 lift, although the single springs may not handle that much lift correctly (I don't currently have any plans to go beyond the 280H cam).

The valve guides should be cut and I should be able to pick up the head early next week.

Thanks

Bob