This is the email back.

As to the turbocharger match we discussed, I’ve done a simple match using the BorgWarner MatchBot, and below is the link to the first match:

http://www.turbos.borgwarner.com/go/FOPKVI

http://www.turbos.borgwarner.com/go/FOPKVI

When you view this match, there are a few things to consider, and keep in mind that this is just a first-shot match, so I’ll point out a few things with some simple screen snips:

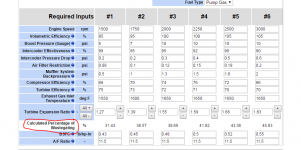

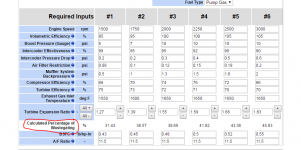

First, the most basic engine and requirement information, including your RPM range:

I also set indicated turbo boost pressure between 5 and 10psi with a ramp-up from 1500-2000RPM, which, given your engine displacement, I think is very possible.

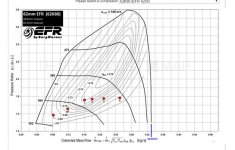

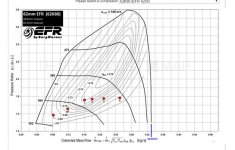

Just these simple inputs spat out a compressor match for the EFR6258:

Frankly, it doesn’t get much better than this; all six plot points are within the map envelope, and, at your peak boost, you’re not only well into very efficient map islands, you’re also well within the peak flow of the compressor, and also, and most importantly, you’re well below the peak speed lines. This is a VERY safe compressor match.

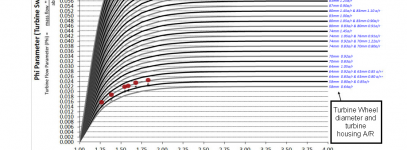

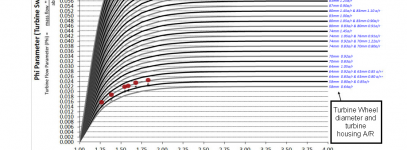

Next is the turbine map, and that did require some manipulation of the wastegate flow percentages, which we’ll discuss further below:

Again, this is a very good match, with the manipulation to the wastegate percentages being surprisingly not as bad as I expected, and, again, this still all falls within the safe operating speed of the turbocharger.

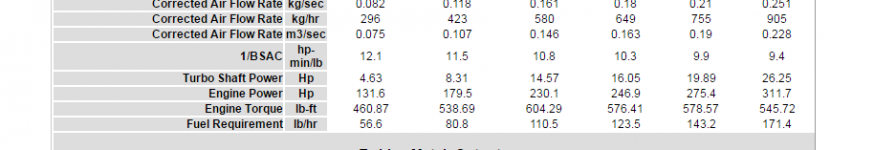

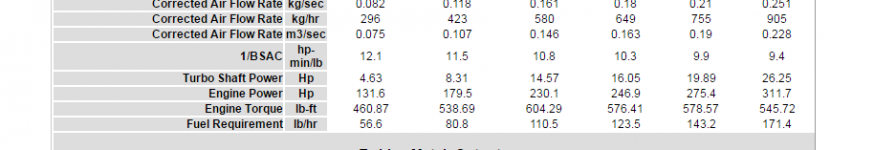

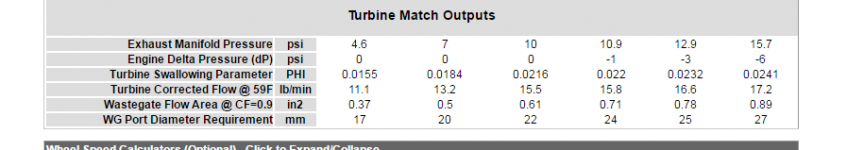

A bit about the calculated outputs here:

I’m not completely sure where you needed to be for total HP, but I know torque was important, and, assuming you can match those fuel delivery requirements and the engine can handle that relatively low boost, you’ll have plenty of usable torque from 1500rpm onward; that’s diesel-level torque right there. It would seem that 200lb/hr fuel injectors would be a good match, and the good news is that those are cheap and easy to locate.

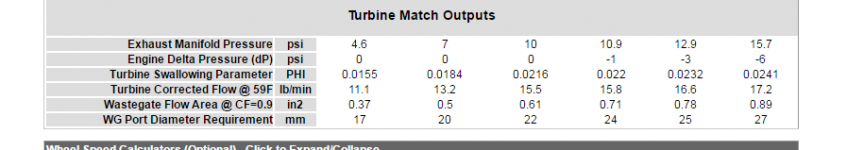

Okay, so far, so good. But we’re not done, because we still have to work on that wastegate percentage change:

Above is the good news; the EFR B1 family, which includes the EFR6258, uses a 31mm WG port, split into two actual passages, so you have the physical materials to handle the flow. The key is going to be to program or set your boost control curve to match the duty cycle of the BCSV (the wastegate solenoid) to the operation of the valve, so that you can maintain fairly high percentages of wastegating to keep that turbine speed down, and to reduce backpressure to make the power you need.

Here’s what I found with regard to that required percentage:

This is the tricky part; the EFR B1 “G” housing (the twin-scroll) has wastegate flow capability of around 40-45% maximum, which is quite high, but it’s right there at the limit of what we’ll be asking for, with that 3000RPM line asking for just over 45%. Can it do it? Yes, I believe it can, but this is where the turbine speed sensor, and, of course, careful control of the wastegate, will ensure that you don’t overspeed the unit.

For what it’s worth, “If” we raise the boost pressure to 12psi at 3000RPM, the wastegate percentage drops immediately to 37.76%. This may be an easy way to not only overcome that possible issue, but, as well, to drive up power, as that also pumps peak HP to 336. Something to consider, for sure.

So, this tells us that you had already done a pretty good job of matching the unit. Good for you.

That takes us to the bad news; the pricing. Below, I’ve quoted the unit, along with companion items you may find useful or necessary:

Complete turbocharger, with “Low Pressure” wastegate canister, and iron bearing housing: $1683.40. As I mentioned, due to the configuration of this unit, we would need to assemble it here, but I just checked, and every component is in stock, so lead time would be very short; 1-2 days maximum.

Turbine outlet v-flange: $34.96 (machined stainless; designed for a 3” downpipe design)

Turbine outlet v-clamp: $55.20 (for the above)

Oil drain flange for your choice of -10 (5/8” i.d.) push-on oil cooler hose, or -10AN hose assembly: $27.70.

Water-port connection fittings for -6AN hose assemblies: $3.01 each (2 required).

All of these materials are in stock.

The oil supply connection fitting is included with the turbo, as a -4AN line. You would need a corresponding oil supply line from a full-flow, filtered oil supply. If you can supply a total length for that line, we can also supply that complete line, and we can also do the same for the oil drain hose, whether you require push-on hose or an AN-style assembly. Ditto for the water lines. All of that said, this is material that I’m sure you can source locally if you have a good hose-and-fitting store nearby.

The remaining connection points for the turbo are fairly simple; the turbine inlet is the T4, twin-scroll (we can supply a flange if your manifold builder has any trouble finding one), and the compressor inlet is a simple 3” hose connection, and the outlet is a 2” connection. When you select an air filter, just use the information above for an airflow requirement, and I would suggest adding about 33% additional flow.

Well what do you ya think pmuller?