Does anyone make a bellhousing to fit a Barra to a c4?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barra 4.0 to a c4 transmission?

- Thread starter 64 200 ranchero

- Start date

Awesome thanks

I found a bellhousing on eBay in California for a lot less money and free shipping.

Here it is:

http://www.ebay.com/itm/Quick-Time-SFI- ... qR&vxp=mtr

Hope this helps.

Here it is:

http://www.ebay.com/itm/Quick-Time-SFI- ... qR&vxp=mtr

Hope this helps.

Thanks, this will probably be a future build

I take it that you have a Barra engine.

Which one? What vehicle are you planning to install it in?

Have you figured out how to handle the engine management without the stock transmission?

A 157 tooth flexplate from a US 250 would work except the bolt holes are 7/16" and the crank is 10mm.

I've got an AU 4.0 engine and am dealing with some of the same problems you'll be dealing with.

Which one? What vehicle are you planning to install it in?

Have you figured out how to handle the engine management without the stock transmission?

A 157 tooth flexplate from a US 250 would work except the bolt holes are 7/16" and the crank is 10mm.

I've got an AU 4.0 engine and am dealing with some of the same problems you'll be dealing with.

I don't have one yet, but I did find one. I'm thinking about doing it, but I wanted to make sure that it can be done. I love my tri-power 200, but it requires a lot of attention. Thanks for the info. It looks like it is doable.

You may have clearance issues with the broad band manifold (BBM) to the left shock tower, and the front of the DOHC valve cover to the hood.

You may have to get the engine as low as possible to clear the hood, or make a scoop.

The Barra engine has an ECU that utilizes engine immobilizers called Smartlock and Smartshield. That's why you'll see some engine solds with the complete wiring harness, instrumentation (dash), transmission, and chassis computer; even the pedal assembly and gas tank. There are companies out there (in Australia) that can reflash the ECU to disable those features and change transmissions.

In order to install the AU 4.0 SOHC engine in my 65 Mustang, I'll have to shift the engine over to the right to clear the BBM to the shock tower.

The SOHC valve cover is not as pronounced as the DOHC, so I should be fine. The ECU for the AU can be reprogrammed with installation of a J3 Chip on the motherboard to bypass the immobilizers and change transmissions.

Good Luck. Keep us posted.

You may have to get the engine as low as possible to clear the hood, or make a scoop.

The Barra engine has an ECU that utilizes engine immobilizers called Smartlock and Smartshield. That's why you'll see some engine solds with the complete wiring harness, instrumentation (dash), transmission, and chassis computer; even the pedal assembly and gas tank. There are companies out there (in Australia) that can reflash the ECU to disable those features and change transmissions.

In order to install the AU 4.0 SOHC engine in my 65 Mustang, I'll have to shift the engine over to the right to clear the BBM to the shock tower.

The SOHC valve cover is not as pronounced as the DOHC, so I should be fine. The ECU for the AU can be reprogrammed with installation of a J3 Chip on the motherboard to bypass the immobilizers and change transmissions.

Good Luck. Keep us posted.

gravelrash

Well-known member

the Quicktime bellhousing is actually the pick of the bellhousings.

Thom the Aussie

New member

Regarding your flexplate issue I know the Aussie 5.0 flexplates fit 4.0 but you have to get a neutral balanced one, I have a few here I check the tooth count if you'd like

Thom the Aussie

New member

Also torque power do bellhousings to suit barra to c4 but if you were interested in a manual you could use an au bellhousing to suit t5 if you wanted a cable clutch or if you want a hydraulic clutch the ba t5 setup will do, earlier 4.0 bellhoungs fit the block but do not bolt up to the sump whereas au sohc and barra will interchange with each other

Have you seen this Barra on ebay?

https://www.ebay.com/itm/Ford-4-0L-24V- ... 29&vxp=mtr

US Customs is the major issue.

Rick

https://www.ebay.com/itm/Ford-4-0L-24V- ... 29&vxp=mtr

US Customs is the major issue.

Rick

rwbrooks50":2jl0mt92 said:Have you seen this Barra on ebay?

https://www.ebay.com/itm/Ford-4-0L-24V- ... 29&vxp=mtr

US Customs is the major issue.

Rick

I've looked at this engine before on eBay. Originally the seller was importing the engine into Washington state but US Customs would not let it into the country so the seller sent it to British Columbia. If you check the auction description the seller states:

The engine is in Surrey, BC and can be collected from a warehouse with fork lift on hand. I can also arrange shipping anywhere in Canada at your cost. If you are in the USA you would need to email a # and I will call to discuss.

There are other auctions for Barra engines. Here is one:

https://www.ebay.com/itm/Ford-turbo-bar ... 0011.m1850

The seller for this auction states:

USA Customers, due to EPA Import Rules this engine is not available to import.

My guess is that the EPA is cracking down on importing engines, as it does vehicles, for emissions.

If this is the case, the engine would have to be built prior to a certain year to be imported.

If the Barra engine is not already in the US, you will have to wait until the EPA anniversary year.

I'm at a crossroads. Should I further build my nitrous 200 tri-power by installing an msd programmable 7 or stop and start working on something else. I have found a complete intech for pretty cheap. I'm wondering if these might help to stuff it in my 60 ranchero. http://musclegarage.com.au/index.php?ro ... uct_id=249

I'm willing to do some cutting and to move the radiator underneath the car if needed.

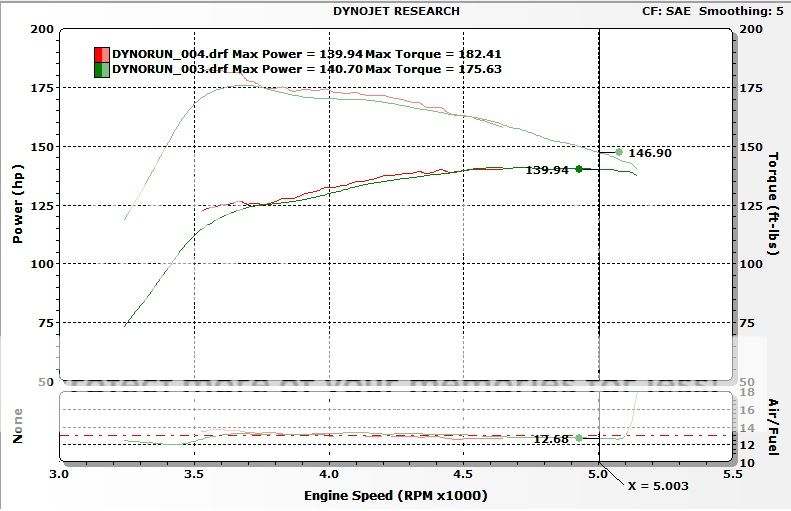

I know intech 4.0 falcons make about 220hp stock. Is that to the wheels or crank? How much power can the stock internals handle? I would use my nitrous setup on it.

Is there a way that I can have new holes drilled into the intech flexplate to use my stall converter?

I'm willing to do some cutting and to move the radiator underneath the car if needed.

I know intech 4.0 falcons make about 220hp stock. Is that to the wheels or crank? How much power can the stock internals handle? I would use my nitrous setup on it.

Is there a way that I can have new holes drilled into the intech flexplate to use my stall converter?

viewtopic.php?f=75&t=78578

You need some Tunnel Vision...

Talk to Peter from Huges Performance. He supplies the aftermarket parts.His Fairlane runs a SOHC Intech.

Since the OHC and cross flow both have the same intake port configuration with even 4.08" center spacings, you can follow Mike1157 and put on a BMW S52 ITB,

They come in 3.545" centers, but you can split and mount them at 4.08" easily.

and if you want to run electronic throttle, there are new safegaurds.

Pete62SOHC":2268pizh said:Not necessarily relevant to my own build, but this is too cool not to share. This '65 Mustang belongs to a customer of mine in Australia. This car is fitted with a Ford Intech AU engine (same platform I'm building). The engine is a max-effort build, featuring such custom items as a billet crankshaft and custom dry sump oiling system. The turbo is a Precision Gen 2 Pro Mod 88mm model, and the engine runs on methanol. It's currently equipped with a Hughes Performance Powerglide transmission and a 9-inch rear axle featuring a 3.60 ratio. This car just recently got finished, and so far has managed to put 1,250 horsepower to the rear wheels as well as run a 7.85 E.T. at 176 MPH!

Ben Pisconeri 65 Mustang.1.jpg

Ben Pisconeri 65 Mustang.2.jpg

You need some Tunnel Vision...

Talk to Peter from Huges Performance. He supplies the aftermarket parts.His Fairlane runs a SOHC Intech.

Since the OHC and cross flow both have the same intake port configuration with even 4.08" center spacings, you can follow Mike1157 and put on a BMW S52 ITB,

They come in 3.545" centers, but you can split and mount them at 4.08" easily.

and if you want to run electronic throttle, there are new safegaurds.

gravelrash":miexcg90 said:the Quicktime bellhousing is actually the pick of the bellhousings.

Peter uses this to hook up the GM auto to the 4.0 liter.

Pete62SOHC":miexcg90 said:QuickTime bellhousing arrived today. This bell fits both the Intech AU and Barra families of engines, and adapts to a Reid Racing bolt pattern. This bell allows the use of a Powerglide or TH400 equipped with a Reid Racing transmission case, or a 4L60E with Hughes adapter featuring a Reid bolt pattern.

AU QT bell.1.jpg

AU QT bell.2.jpg

But, you know, the 4.9 big six can fit too.

The radiator can go in the back of the pickup deck, like the Gila Monsters old aftercoolers. The Werlts your Oyster...

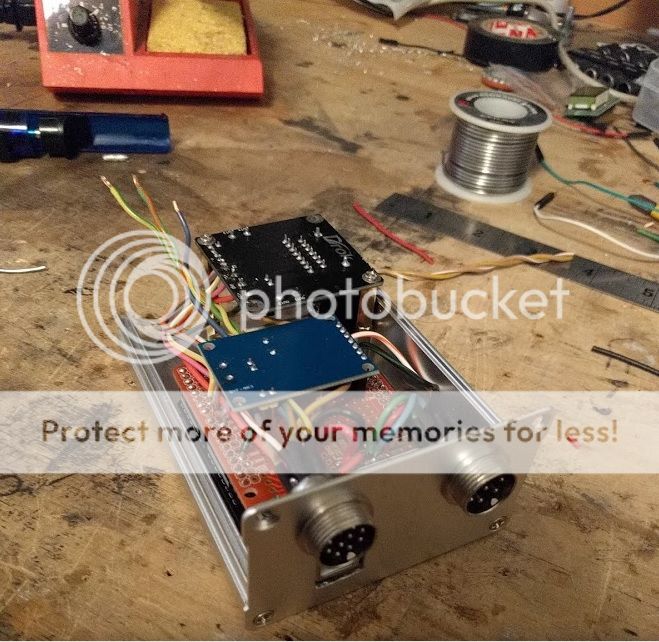

On the electronic throttle, this from JP on FEP and Stangnet

https://youtu.be/KVogEmmQZTs

EFi is much safer than servo control of a carb throttle blade.

BMW , Ford, Toyota and GM have worked through the safety protocols, and when NASA was asked to inspect the code for the Lexus 125 mph throttle jamb-on fatilies, it wasn't the coding that was an issue, the Electronic throttle has safegaurds these days.

In 1985, the BMW M5 had a throttle jamb on at Mibrook (MIRA, England), and the whole industry got into sorting out how to do electronic throttles better.

I'd like to tell everyone that it was you who first got me into exploring electronic throttle, Josh.

viewtopic.php?f=1&t=67077&p=515913#p515913

On the Turnigy Servo Tester

64 200 ranchero":miexcg90 said:i bought this type of servo setup, i think i can adapt it somehow http://www.youtube.com/watch?v=KSmRWhTQ ... re=related

xctasy":miexcg90 said:I'm all for innovation, but a word of caution.

I personally wouldn't ever use Servotronic accelerator cable actuation even for secondaries unless it is a factory set up. Too many issues over the recent Toyota/Lexus failsafe Nipondenso and American made equivalent electronic throttles have gone under the bridge. BMW's M5 first used a fully electronic set-up in 1986, and there were a spate of over centre throttle jambs at MIRA in the UK (by Wheels Magazine, at 145 mph in a 3.5 liter Bemmer), and documented failures elseware...this on a West German TUV approved set up, the great grannies of all conservative legislators.

When Ford made fly by wire standard on Explorers and Falcons in 2003, and on Toyota diesels in 2002, I realised that creating a vacum secondardary or fly by wire system was possible to take load of the accelerator pedal.

Use prudent judgement, but I wouldn't want to ever aid and abbet working with any servo system like that unless its got an armload of SAE degree engineers to help me out. You can pick up a smashed remote control plane when a servo fails, but there would need to be some subsidary failsafe measures before I'd ever use one of those on my tripower.

Now you have given me more to think about. A 300 would definitely be a way easier swap and I wouldn't have to deal with all the computer junk. I could probably do the ls head swap, but maybe go a step further and get a set of performance heads to combine. My new goal is to keep up with the Japanese inlines. I don't think that my little 200 can do it.

I don't wanna stop anyone making a bold step Ford. The offers Rocklord has made, don't be afraid to take it.

Stock Ford Intechs are 205 to 235 hp net at the flywheel, and they are sweet yet punchy engines with a lot of character. The Barra's add another 30 hp before turboing. 265 hp is a lot of fun. With modifications such as turboes, this old iron block with an OHC conversion is way stronger than any Nissan or Toyota six. I deeply respect all aspects of engineering Bill Dix and his team infused into this engine in 1987; the design then got uprated by Ford Broadmedows Australia, with consultancy help from Aston Martin Tickford, who were involved via consulting work, with Jaguar. Ford USA and Jac Naser, Ford Australia's three year boss on a fast track to Dearborn, they made the XR6 and XR8 hardcore performance cars that also handled, braked and cruised the cement oval tracks of You Yangs. In terms of dollars per mph, 145 mph and low 15 second quarters were exceptional. It only grew when the XR6 level of power was handed to the base cars in the late 90's. The growth in weight was answered with more power via the twin cam head and at the same time, a turbo. The engine was finially making more than the best 1983-1987 AIT and Mike Vine 255 to 350 hp 4.1 x-flow turbos. Ford Australia had deliberately kept out of the performance in line six cylinder market in the Australian and New Zealand because the economics were not favourable, and the Japanese Mazda concern was going to be where to real economies of scale were. Ford in 1990 had Aston Martin, Jaguar, the Rotary engine, Mazda and from 1982 to 1990, Ford Australia was number one, and with a brace of 164 and 186 hp sixes that did 16.3 to as little as 15.5 seconds to cross the standing 1/4 mile, who needed 255 to 350 hp turbo cars

Don't say no to an Intech if your hearts set on it. Othets will come and want to do the same thing. Dearborns whiz kid who made the XR6 happen was Edsel Ford II. He and Jac Naser knew exactly what they were doing when the XR6 and XR8 hit town in late 1991. They might have a funny acent, but the whole idea of a blQQdy good big inch OHC was very much a De Lorean style high tech Pontiac 230 idea, and the public loved them

The backup electronic systems are American, but much development was from Tickford and Prodrive developed, under contract to Ford Australia. The huge backup comes from extensive sales, huge use in oval track racing, and a need to whoop 5 liter V8 ass. Its stablemate was for many years the EFi 5 liter US import E7 GT40 headed Cleveland made ohv iron V8. It was therefore benchmarked to petform ad well as the best 5.0's.

Stock Ford Intechs are 205 to 235 hp net at the flywheel, and they are sweet yet punchy engines with a lot of character. The Barra's add another 30 hp before turboing. 265 hp is a lot of fun. With modifications such as turboes, this old iron block with an OHC conversion is way stronger than any Nissan or Toyota six. I deeply respect all aspects of engineering Bill Dix and his team infused into this engine in 1987; the design then got uprated by Ford Broadmedows Australia, with consultancy help from Aston Martin Tickford, who were involved via consulting work, with Jaguar. Ford USA and Jac Naser, Ford Australia's three year boss on a fast track to Dearborn, they made the XR6 and XR8 hardcore performance cars that also handled, braked and cruised the cement oval tracks of You Yangs. In terms of dollars per mph, 145 mph and low 15 second quarters were exceptional. It only grew when the XR6 level of power was handed to the base cars in the late 90's. The growth in weight was answered with more power via the twin cam head and at the same time, a turbo. The engine was finially making more than the best 1983-1987 AIT and Mike Vine 255 to 350 hp 4.1 x-flow turbos. Ford Australia had deliberately kept out of the performance in line six cylinder market in the Australian and New Zealand because the economics were not favourable, and the Japanese Mazda concern was going to be where to real economies of scale were. Ford in 1990 had Aston Martin, Jaguar, the Rotary engine, Mazda and from 1982 to 1990, Ford Australia was number one, and with a brace of 164 and 186 hp sixes that did 16.3 to as little as 15.5 seconds to cross the standing 1/4 mile, who needed 255 to 350 hp turbo cars

Don't say no to an Intech if your hearts set on it. Othets will come and want to do the same thing. Dearborns whiz kid who made the XR6 happen was Edsel Ford II. He and Jac Naser knew exactly what they were doing when the XR6 and XR8 hit town in late 1991. They might have a funny acent, but the whole idea of a blQQdy good big inch OHC was very much a De Lorean style high tech Pontiac 230 idea, and the public loved them

The backup electronic systems are American, but much development was from Tickford and Prodrive developed, under contract to Ford Australia. The huge backup comes from extensive sales, huge use in oval track racing, and a need to whoop 5 liter V8 ass. Its stablemate was for many years the EFi 5 liter US import E7 GT40 headed Cleveland made ohv iron V8. It was therefore benchmarked to petform ad well as the best 5.0's.

For cross member update, I'm sure you've followed Bob the Builders 250 powered 62 Chero. User name 62Ranchero200

memberlist.php?mode=viewprofile&u=120315

He used angle iron to make new engine mounts, kept the front free of a cross member, but added a new cross member buttress on the floor with good results. His 62 has the earlier small ball joints.

There are loads of options, and good advice right here.

memberlist.php?mode=viewprofile&u=120315

He used angle iron to make new engine mounts, kept the front free of a cross member, but added a new cross member buttress on the floor with good results. His 62 has the earlier small ball joints.

There are loads of options, and good advice right here.

64 200 ranchero":g50ah0kc said:I know intech 4.0 falcons make about 220hp stock. Is that to the wheels or crank? How much power can the stock internals handle? I would use my nitrous setup on it.

Is there a way that I can have new holes drilled into the intech flexplate to use my stall converter?

i'm not up on the later ford motors - but I 'think' these two articles I scanned may help :

they are PDF's