sixty-2-tonfalcon":3navb2cf said:

Youre leaning out @5500, especially with the rate of air coming in, and the lack of fuel the 1bbl can keep for the fuel ratio to keep up with the demand of the engine.

No, the A/F ratio meter was showing it was OK,

It just feels like it runs out of air flow ability, that's all.

Runs clean and smooth and just pulls along at that RPM (RPM's are increasing slightly, but not very fast....).

It's acting like the cam or carb is way too small or something, the power just stops right there.

sixty-2-tonfalcon":3navb2cf said:

Guides and seals are fried, rings are worn out.

Got that right.

If you let it idle for 30 seconds there is a huge cloud of blue smoke when you give it gas!

I don't think the rings can't "Handle" boost, other engines can without problems. They are just really worn. Maybe some piston damage, too.

Here is an idea, let me toss it out there.....

I am thinking of building my new engine,

all fresh,

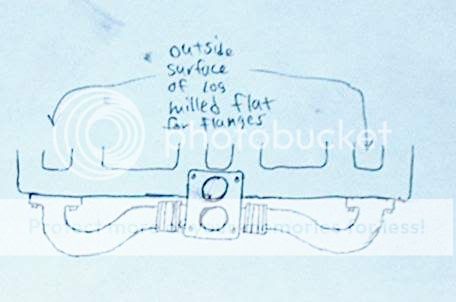

but stock head, stock cam, etc. and same exhaust log and 1 bbl carb.

I mean, I STARTED with a 150,000 mile engine to begin with!!

Wouldn't a FRESH engine have more power with the same combo???

I think I am going to try that!