Krogdahl heads, the DOHC 4v per clyinder XR6 Turbo engine, Duggan heads, 2V Falcon heads, first country to numerically port (CNC machine) cylinder heads...what is it with Aussies and there sicko fixation with cylinder head modifications?

Well, its not a new trend, and heres some history to prove that these boys have been at it a little longer than most Americans may realise...

Background:

Unlike the USA, few V8 engined cars were sold as a staple diet to Australians after World War II. The mainstay of Austrailan motoring was the venerable Side Plate Six....not Chevies stovebolt, but a mini Stove bolt hitting the 132.5 cubic inch mark ( 2. 171 liters) and disposing of a mighty 80 gross ponies from its six port head. From 1948 until its demise in 1963, the so-called GM Holden Grey was the only cheaply available game in town. Its strentghs were six cylinders, a detachable head and a huge factor of safety built into its steel crank and rods.

Its big black mark was a cylinder head which gave possesed the same kind of panche for intake and exhast flow as a camel passing through the eye of a needle. To say it was Bad was a complement.....

So cluey Aussies, far away form Detriots emerging power, were stuck with grinding up the stock head. Some were able to extract 130 hp with Triple 1.75" SU carbs and 12:1 compression, a hot 285 degree cam using the stock block. Others, brough up from motorcyling backgrounds, had other wild ideas.....making there own out of alloy stocks and dies!

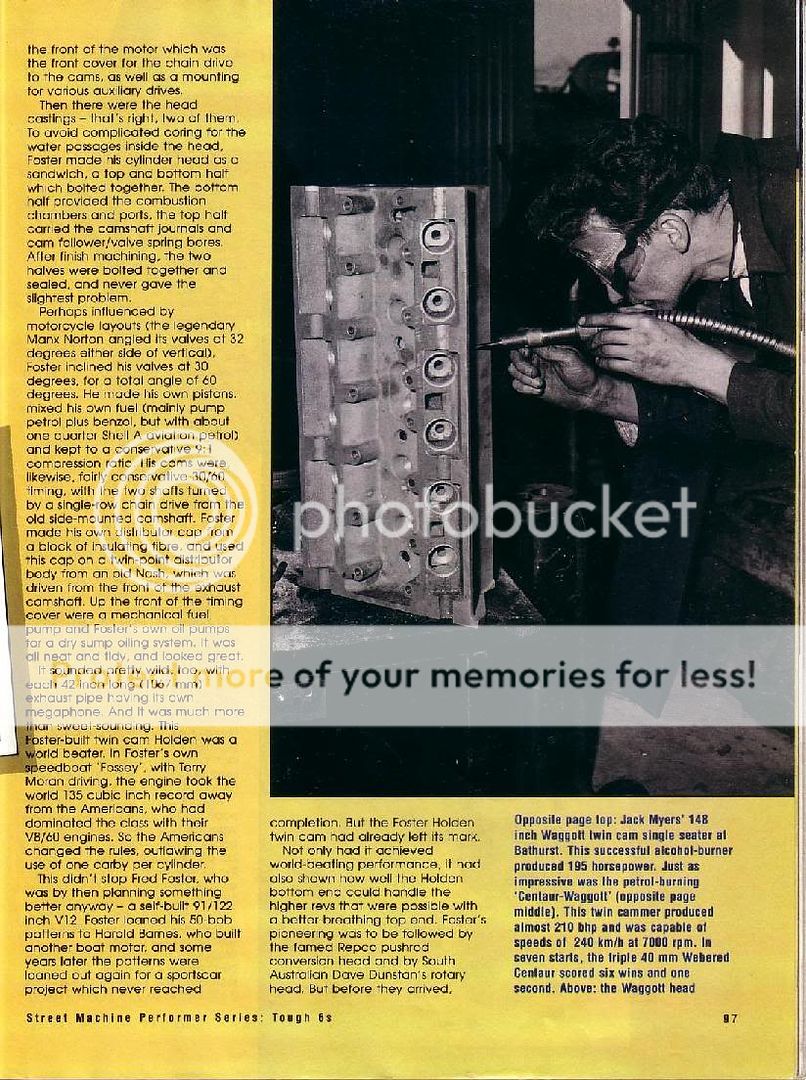

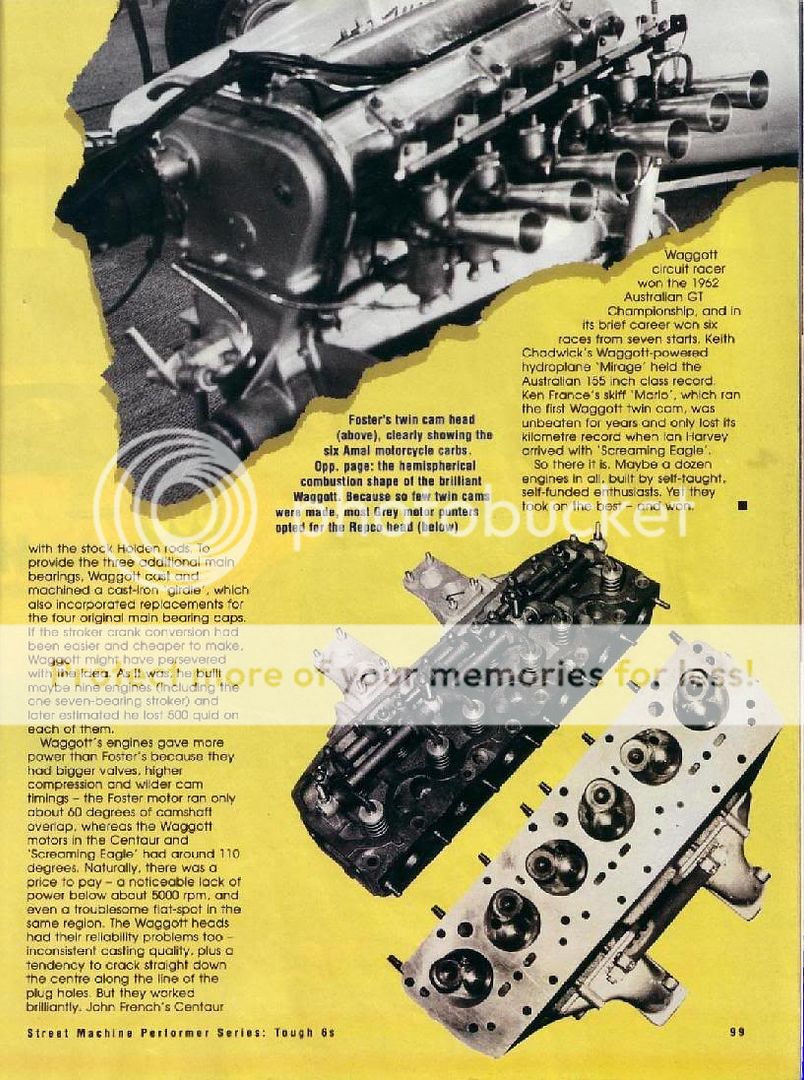

Example One: Late 1952. A self taught and fulltime metallurgical genius Fred Foster got the ball rolling with his six part alloy sandwich. It was a brilliantly simple design based on some $5 plans chalcked into his floor at Fosters factory. There were separte castings for each over head cam valve cover, another casting down the front of the engine which was the front cover for the chain drive to the cams, as well as mounting for various auxiliary drives. Then there were two head castings , modled of the Norton Manx valve layout, and this amounted to a 140 hp engine with just 155 cubes and a very mild set of twin camshafts running 270 degrees duration. With six carbs, the skiff 'Fossey', this little grunter took the American 135 cubic inch records from the V8/60 Flattie Ford V8'S.

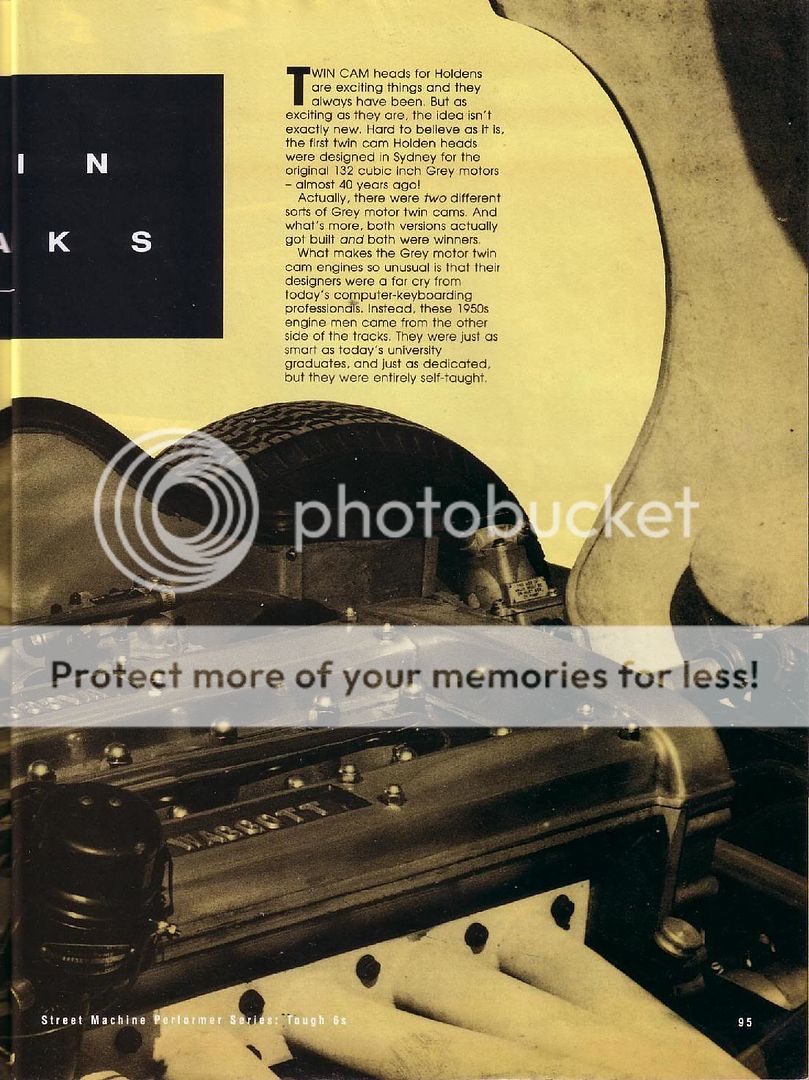

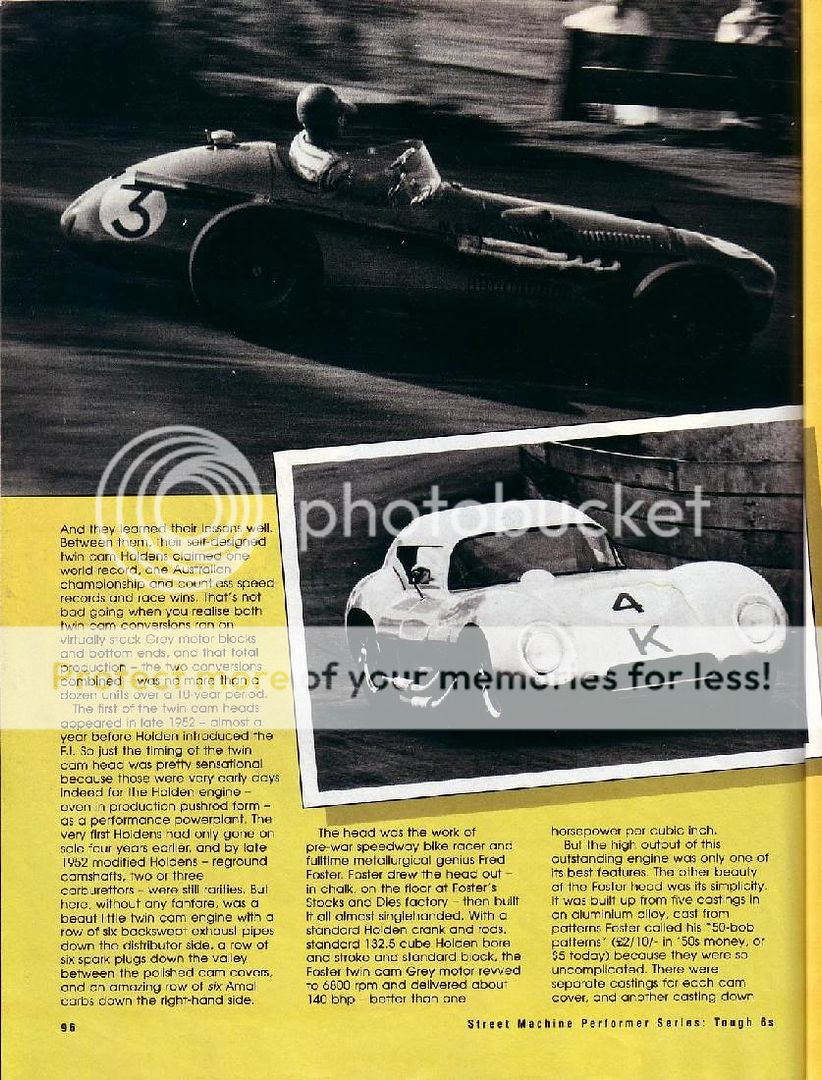

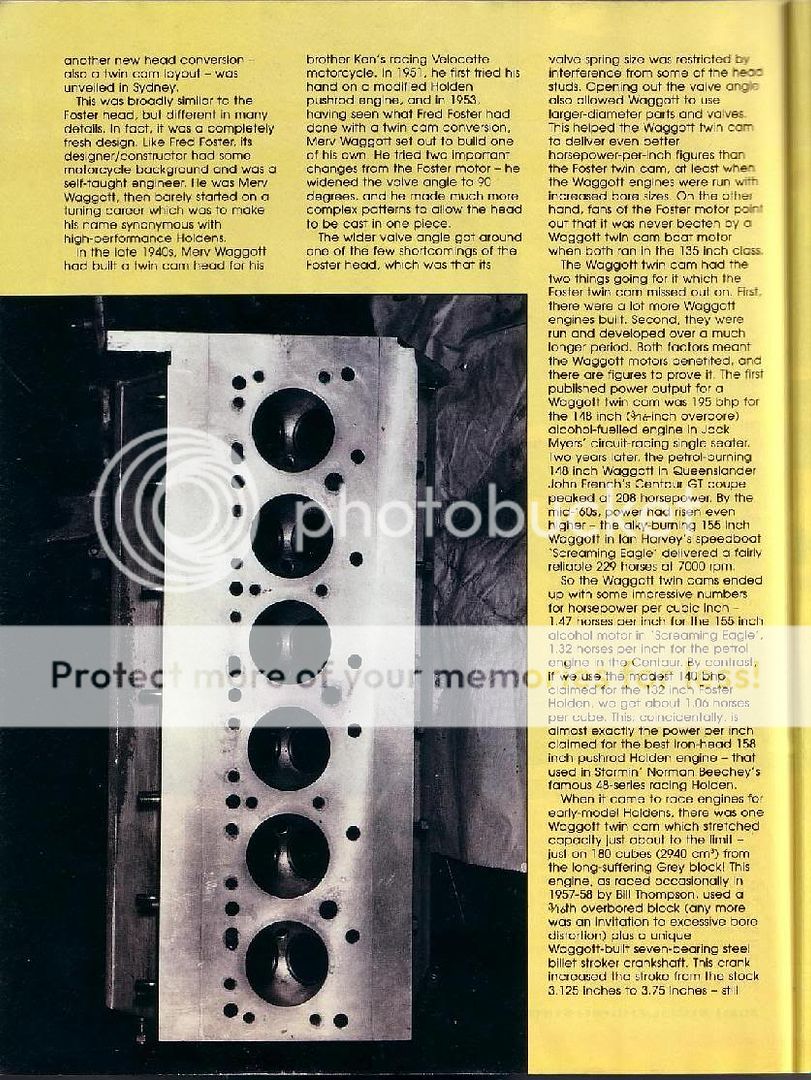

Example Two: 1953 to 1962. Very scarce, as only nine were minted, is the Merv Waggott-designed twin-cam head for the sideplate Holden. Sold only as a complete competition engine, where the Waggot-created alloy head was mounted on a strengthened, dry-sumped Holden block, this complex design racked up some outstanding successes. Chain driven camshafts operated on inverted bucket followers to open wide-angled valves, which worked in full hemispherical combustion chambers for maximum breathing efficiency. The head was a full 12-port crossflow, breathing through either triple double-choke sidedraft Webers, or six individual Amal motorcycle carbs. The Sydney-based engineering company made almost everything, from camshafts through pistons to oil pressure pumps and timing chain chest. On 40 DCOE Webers, power output was just 186 hp, although it rose dramatically to 202 hp when the carburettors were changed to the six Amals.

These engines ended up in hydroplanes mostly. The 155 cube alcohol engine in 'Screaming Eagle', where 229 hp came out a 7000 rpm inthe early 60's. Then there was also a wildly streached 180 cube six (2.94 liters) which was done via a 3.75 inch seven bearing conversion, a caged crank case, and a doweled block with a 500 thou plate to tie the thing together. It's unreported just how much power this had...but it was almost 36% bigger within the confines of the 132.5 cube stock block.

Well, its not a new trend, and heres some history to prove that these boys have been at it a little longer than most Americans may realise...

Background:

Unlike the USA, few V8 engined cars were sold as a staple diet to Australians after World War II. The mainstay of Austrailan motoring was the venerable Side Plate Six....not Chevies stovebolt, but a mini Stove bolt hitting the 132.5 cubic inch mark ( 2. 171 liters) and disposing of a mighty 80 gross ponies from its six port head. From 1948 until its demise in 1963, the so-called GM Holden Grey was the only cheaply available game in town. Its strentghs were six cylinders, a detachable head and a huge factor of safety built into its steel crank and rods.

Its big black mark was a cylinder head which gave possesed the same kind of panche for intake and exhast flow as a camel passing through the eye of a needle. To say it was Bad was a complement.....

So cluey Aussies, far away form Detriots emerging power, were stuck with grinding up the stock head. Some were able to extract 130 hp with Triple 1.75" SU carbs and 12:1 compression, a hot 285 degree cam using the stock block. Others, brough up from motorcyling backgrounds, had other wild ideas.....making there own out of alloy stocks and dies!

Example One: Late 1952. A self taught and fulltime metallurgical genius Fred Foster got the ball rolling with his six part alloy sandwich. It was a brilliantly simple design based on some $5 plans chalcked into his floor at Fosters factory. There were separte castings for each over head cam valve cover, another casting down the front of the engine which was the front cover for the chain drive to the cams, as well as mounting for various auxiliary drives. Then there were two head castings , modled of the Norton Manx valve layout, and this amounted to a 140 hp engine with just 155 cubes and a very mild set of twin camshafts running 270 degrees duration. With six carbs, the skiff 'Fossey', this little grunter took the American 135 cubic inch records from the V8/60 Flattie Ford V8'S.

Example Two: 1953 to 1962. Very scarce, as only nine were minted, is the Merv Waggott-designed twin-cam head for the sideplate Holden. Sold only as a complete competition engine, where the Waggot-created alloy head was mounted on a strengthened, dry-sumped Holden block, this complex design racked up some outstanding successes. Chain driven camshafts operated on inverted bucket followers to open wide-angled valves, which worked in full hemispherical combustion chambers for maximum breathing efficiency. The head was a full 12-port crossflow, breathing through either triple double-choke sidedraft Webers, or six individual Amal motorcycle carbs. The Sydney-based engineering company made almost everything, from camshafts through pistons to oil pressure pumps and timing chain chest. On 40 DCOE Webers, power output was just 186 hp, although it rose dramatically to 202 hp when the carburettors were changed to the six Amals.

These engines ended up in hydroplanes mostly. The 155 cube alcohol engine in 'Screaming Eagle', where 229 hp came out a 7000 rpm inthe early 60's. Then there was also a wildly streached 180 cube six (2.94 liters) which was done via a 3.75 inch seven bearing conversion, a caged crank case, and a doweled block with a 500 thou plate to tie the thing together. It's unreported just how much power this had...but it was almost 36% bigger within the confines of the 132.5 cube stock block.