Georg Wilhelm Friedrich Hegel":v5ydj0hb said:

The only thing we learn from history is that we learn nothing from history

62Cometman":v5ydj0hb said:

As always X i appreciate your honesty and info, though i don't fully agree with you its nice to see a varying perspective, if i knew anyone in the area that would take on the project of chopping off the log intake and welding a plate on in its place i would jump on the opportunity and i feel most of my issue would become second thought, such isn't the case here in my little slice of the country.

Log removal is NOT required. Anytime you have the carbs situated at the feeding zone, all you need is enough fuel. Air flow is assured when its not bending through seven 90 degree bends.

Don't get me wrong...I love

67straightsix's (and

Fast64Ranchero,

JTTurbo, Big

Al the Hackmiester, who's tool of choice was also the Sawzall).

You know what? On just 200 cubes, I'll bet 67straightsix's engine will be a shoe in in at 400 flywheel hp.

Man, that's an engine!

But Logectomy is not needed

at all when you move to the Offenhauser method of fuel delivery. The elimination of the bends to the cylinders, that's its sole advantage, and on all Ak Millers early creations before he was forced to turbo charge and propane everything to meet California emissions, all his early efforts were multiple carb weld on or bolt on adaptors, and he'd go right up to rwhp figures of, oh, I don't know, 115 hp with Twin SU's, 125 with four Kehins, and well over that with his best Offenhauser bolt on creatings, culminating in the Mavi GT 250 CUBIC , his last Tri Power concept car, and that was a stout sub 15 second car with just forged Jahns pistons, a 480 lift, 280 degree at lash cam, and he took care of the block short fall via the custom pistons. So that cheap, effictive technology makes a lot more horsepower than a flow bench would indicate.

FordSedanDelivery copied Ak Millers 250 build, and got 14.39's at 99 mph.

I think its all about being a Ford Six disciple, and following the text book US I6 engines that ACTUALLY worked.

I still have trouble understanding how anyone can bolt a 200 Ford Autolite 1100 or 240 Ford Autolite 1101 center carb and two tiny 85 hp Holley 1904 144 carbs, and

suddenly get 14 second quarter mile passes from such tiny little carbs with so little carb venturi area. That goes all against everything I know about port injection and Independent runner carbs.

You know what? I don't know sh!+!

But thats the lesson of all those 60's to early 70's Tri Power Ford sixes. The log head wasn't as much of a dog if both the 2V 250 head and Tri Power produced the same results.

I

do shake my head a little bit given how much advanced engineering existed in 1960 to make just 156 hp at the flywheel from 156 cubes.

Its not about agreeing, its about benchmarking something that will work for you, that you can do, where you are. Genius is about copying something that works, and not telling anyone about it.

There is no one here whos done a Round Body Barra or Ecoboost. Its probably easier to book yourself on a proposed space travle or Moon Mission than to do the specific engineering work required to get them to run in an unsuited frame that never took those engines. I have seen an EA CFi 3.9 liter engine in an early Falcon, and it fitted okay. There is an Aussie Speed 4-bbl that makes sapce to fit the Barra engine, but its a basically way bigger than a 4.9 EFI truck engine, with less capacity, 4.08" bore spacings instead of 4.48, 9.22"deck rather than 9.8, worse conrod ratios, undersquare, and weighes the same as an Iron 4.9 Carb 1-bbl engine.

I've seen a few 300 Ford round bodies...its just some

PowerBand style 250 firewall hammer work, and then talk to

Frenchtown Flyer about what sort of carbs you'd like to run.

But I do want to encourage! :mrgreen:

To make 200 rwhp, with a T5, that would just need a lowly 170 with simple induction up grades and a turbo. 253 hp is the magical value to make 200 rwhp with a 5 speed and an 8" inch axle.

It seams the things Ford USA rushed into and did fastest, lasted longest.

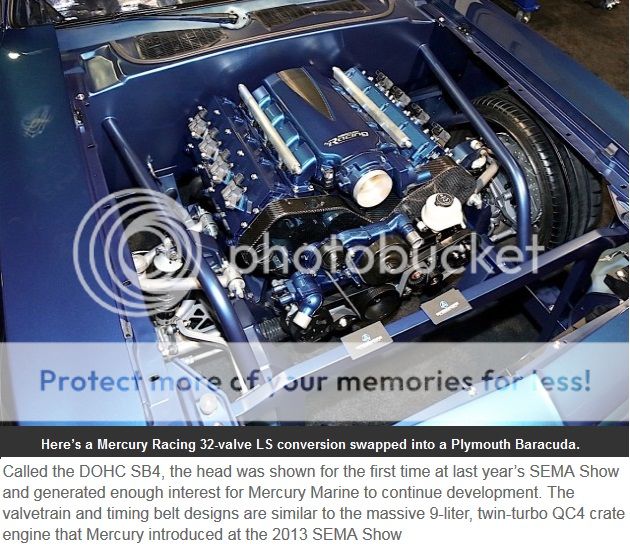

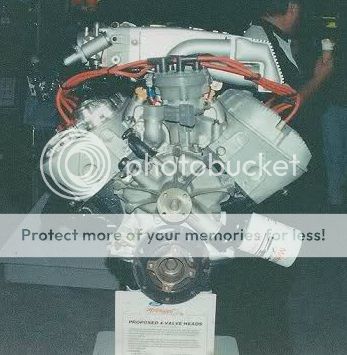

If you want horsepower, get this...and a turbo. You don't need no 4 cyl engine or DOHC Barra...

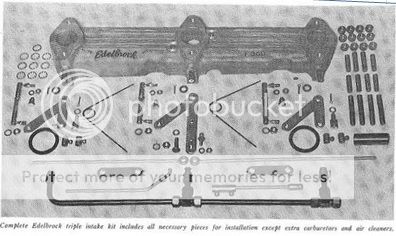

If you want to "out do" yourself, three Holley 94's or Stromberg 97 2-bbls with opened out holes.

Three NOS Offenhauser 223 Ford or 235 Chevy 2 bolt 1-bbl 2-5/8" to 3 bolt carb adaptors slotted for three Stromberg 97's.

You would be better off making your own short 1/4" plate alloy adaptors and using countersunck cap screws, and then opening each outer hole up to 1.5" via a better iron tube like soldmy66's. All this stuff is around, and buying it is cheap. Modifiying it to work, even cheaper.

http://www.ebay.ca/itm/NOS-Offenhauser- ... yB&vxp=mtr

http://www.ebay.ca/itm/NOS-Offenhauser- ... yB&vxp=mtr

Its looking more an more like half Ak Millers Glasspar G2 special 1960 V8 engine.

viewtopic.php?f=1&t=76330

xctasy":v5ydj0hb said:

....

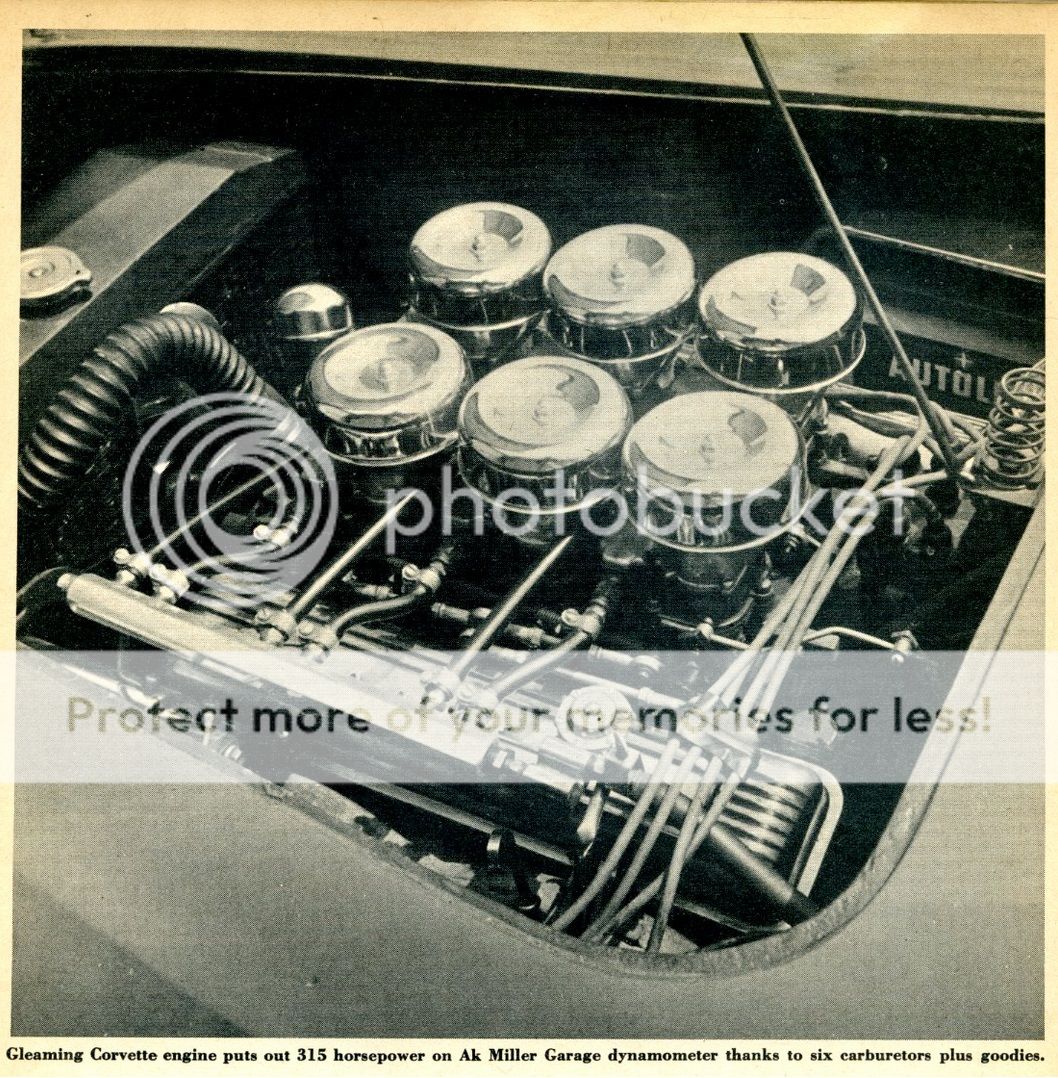

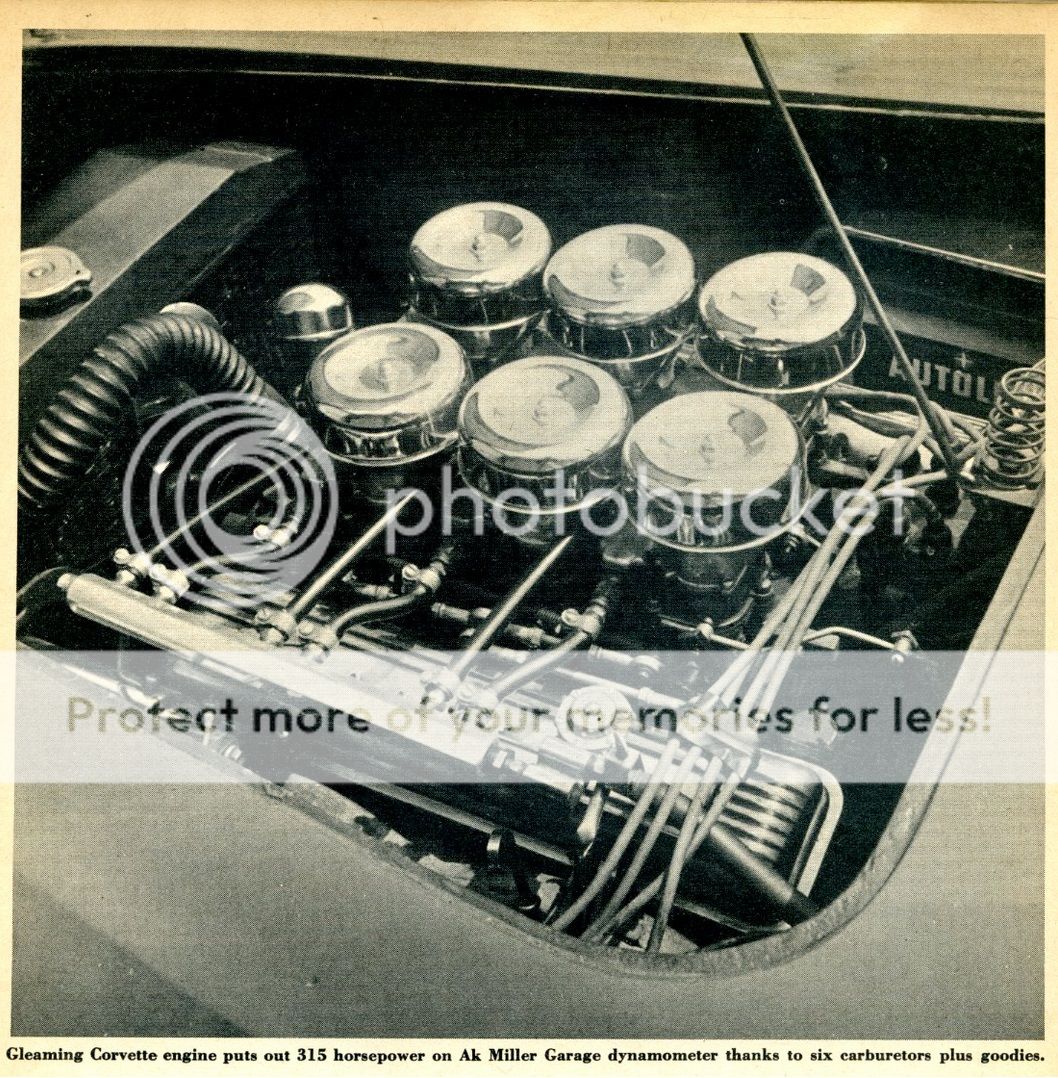

I'm an Ak Miller advocate, he started out on the crazy Glasspar G2 Special with a "352" stroker 283 Chevy with 4" bores, 3.5" stroker crank, and six Deuce Stromberg 97's for 315 flywheel horspower net

That's

Twelve 23.8 mm venturis of 15/16ths, or 8.28 sq inches of carb venturi area on a 352 cube engine.

42 cubes of engine for every square inch of carb. He made 972 cfm at 1.5'Hg work within the confines of the low hood. 162 cfm of Stromberg 97 2-bbl, six times. 229 cfm at 3" Hg each.

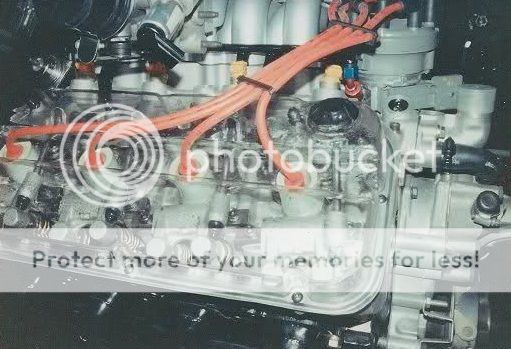

Miller was a six cylinder kind of guy generally, but was a total V8 die hard in terms of aspiration, and although his Four Keihin 37 mm carb 1967 Mustang fit up yielded

158 flywheel hp from just a mildly cammed and headered 200 six, it was actually a Port on Port on the outer carbs (feeding cylinders 1 and 6 via an offset 1-1/2" pipe, and One venturi per 2 cylinders feeding 2, 3, 4, 5). That's why it had some issues with a flat spot off idle.

Lets see. 352/2= 176 cubic inches

315/2= 157.5 hp.

Add a 9 pound turbo boost ratio of 9+14.7/14.7 or 1.61, and you have a 253 hp potential engine right away, Dr Bombay.

That will be able to almost match a naturally aspirated 1961 280 HP net 45DCOE Weber 170 Falcon from Australia.

viewtopic.php?f=1&t=76629

xctasy":v5ydj0hb said:

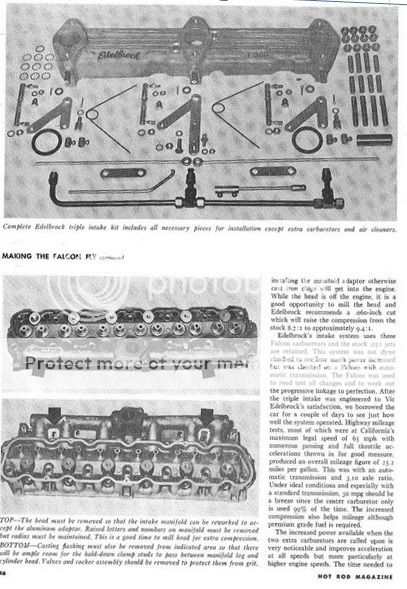

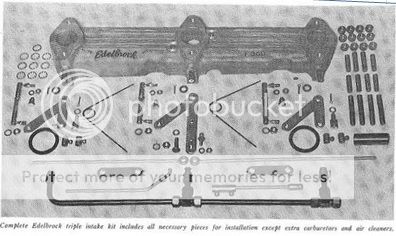

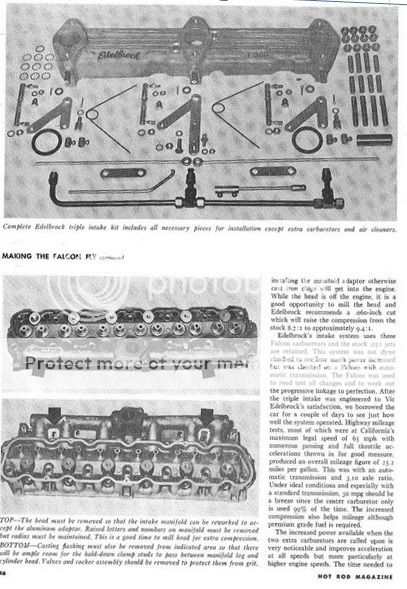

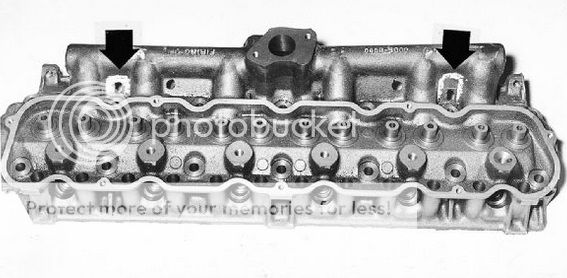

Confirmation of the 170 back to 144 differences is the 5017 Offehauser and its running mate for the first few years, the old Edelbrock F360 aluminum adaptor.

They both "sit down" and "hug up" on a 144 because its a skinnier "dawg turd". The very slightly bigger 170 intake runner variances were created by ovaling out the heads log section. The 5205 therefore rides up a little more, but nothing an O ring seal replaced with Devcon/JB Weld cant fix.

Care of Hot Rodding the 144 Ford 6 page 46

This enlargement care of

http://image.mustangandfords.com/f/3552 ... _heads.jpg

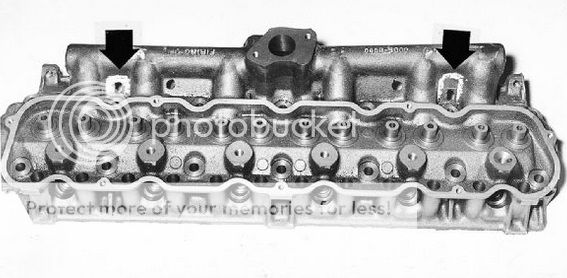

At first glance, Ford light-duty six heads all look the same. This is a '60 144ci cylinder-head casting-a C0OE. Casting numbers and dates are important for identification. The earlier heads have smaller valves and chambers. Valve and chamber size increased with increasing displacement.

The stock 170 C0

DE6090 head was trim externally, but fatter than the 144 C0-C3

OE

In this article, the stoked out Paxton blown Tri-power 144 is my pick of delectable engines. Two other articles, May 1961 1960 "Stroker" 144 Comete with blower with 2-bbl Holley 94 2-bbl w/ mounting plate, blower hat and belt tensioner, special distributor & fuel pump/pressure regulator, JE 1.436" compression pistons with the longer than factory 170/200 4.715" rods, (the earlier 144 4.855" rods), 12 thou deck register, 170 valves...

They were doing it all back in 60 to 61!

The 2V 250 Falcon used the Stromberg WW 2-bbl carb like the one used in this artocle from Jalopy Journal

https://www.jalopyjournal.com/forum/thr ... it.625962/

Page 102 missing sadly.

July 1960, Hot Rod had an article "Supercharging the Compacts"

Remember, the Pumpkin Seed was making 156 hp net per 156 cubic inches in 1960, and 187 hp net on Alchol with its Mechancial Fuel injection. A two-way average of 205.949 mph at Bonneville.

https://www.hemmings.com/blog/2017/04/0 ... l-of-fame/

That's just a Vern Hule, Stroppe Brothers Falcon 144 bored out, same as the 8500 rpm rev limit Hydroplane racer engines; (accomplished by sawing off the stock integrated intake manifold and installing a custom adapter plate) and a set of very long headers.

Best stock rear wheel horsepower for a so called 170 was 47 in 1961, 18 less rear wheel hp than the 65 hp or so Ak Miller made on his 115 hp gross 1967 Mustang engine before the tuning process started.

The knowledge base in 1960 was further ahead than the current US knowledge base....compact little I6's were making more hp per cube.

All this talk about other engine swaps.. all good, but the Pizza base you have can take it all.

280 hp proves it!

, Im honestly just shooting for the mid 200s and anything more than that would be a plus.

, Im honestly just shooting for the mid 200s and anything more than that would be a plus.