Baxsie

Well-known member

Yes, as far as I can tell, the PIP signal from the module is a pass-through of the hall-effect sensor. So the largest function of the module is to close the big hole in the side of the distributor. Also, as far as I can tell, the hall-effect sensor in the Holley and the Ford are identical - at least the molded plastic is identical.I am reading this as, the module serving as a passive interface. It will have no duty as an ignition control module anymore?

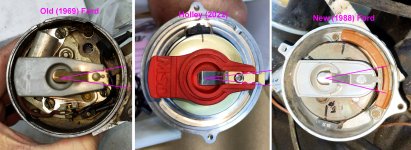

So it appears that Holley basically copied Ford's vane and sensor design (not that there is anything wrong with that).

Yes it will be a passive interface and the Sniper 1100 takes on the ignition timing duty.

It can still be used as a TFI ignition coil driver but then you are back to the heat issue that caused Ford to move the unit remote from the distributor.

Ah, that explains why the module has a big aluminum plate as its back, which mates with thermal paste to the distributor housing. I put it back the same way with some thermal paste I had on hand. I do not know what they were thinking, trying to cool electronics by thermally coupling them to a hot motor

I did not mention above, but I used some high temp RTV to secure the black plastic hall-effect sensor assembly to the shaft so it is completely immobilized. The Ford design has an arm to lock it in place, but it still could wiggle slightly. Not anymore.

I will say that the Ford distributor has amazing mechanical design. Oil passages inside the shaft, even a special washer with an oil passage. There is a spiral track on the outside of the shaft to manage oil distribution, pure end-stage mechanical design evolution.

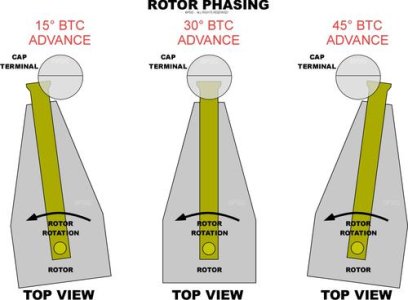

Another -- possibly minor -- thing about the Ford design is that the rotor has a wide arc at its tip. This design should allow the rotor to be close to the points in the cap for a longer period, allowing more freedom for the ECU to change the spark timing. The Holley rotor has a narrow tip.

I will be away from testing this distributor for a bit, I need to make a throttle cable, get the throttle body mounted, finish the fuel lines, and do all the wiring. Plus I'll be away for a few days so it may be a while before I update. I'll post progress on all that other stuff over on the My 1969 F100 Big Block Six 240 Holley Sniper EFI Train Wreck Project thread.

Last edited: