Ive read/looked at this tech article many times, and I've been wondering what do these mods to the flywheel/flex plate look like?

thanks in advance,

-ron

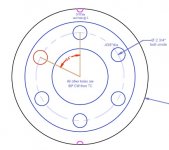

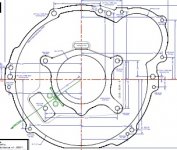

If I used parts (flywheel/flexplate) for a 250 instead of a SBF, would I still need to rebalance?[url=http://www.fordsix.com/V8Bell.php:3rv7r8r5 said:Adapt a V8 Bellhousing[/url]":3rv7r8r5]6. The V8 flexplate needs attention too. Have your machinist drill new crank holes onto the V8 flexplate using the I6 enforcer ring or the I6 flexplate as a template. The counterweight needs to be removed. Then re-balance the flexplate to zero imbalance.

thanks in advance,

-ron