I have a 95 4.9 so we may find out!1990 through 1996 4.9 EFI

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

300ci 4.9l engine swap from a 95 to a 63 Econoline. Some injection related questions.....

- Thread starter Walken100

- Start date

This applies to 300ci engines only

philford

Famous Member

volvos of the 80's , which I just have more experiece with , have a prepump in the tank and a main pump under the car, under the driver's seat.

if the tank pump goes bad, then the car ruins fine until it reaches about half full then she has issues. it wont run at all without the main piump.

I guess the right way would be to use something close to the OEM setup with the pre pump in the tank and yea you need a return line for FI. But it is likely possible to cheat and pull fuel from the bottom.

I think the reasoning is a rubber line can go rotten and leak the whole tank so it was revised for safety reasons. and both would use quite good quality materials for fuel lines. I dont know but I suspect that it was a later safety requirement. maybe mid 85 or so. ?

I have a early 85 porshe 944 it takes fuel from the bottom , that has no in tanlk pump. but it does have an opening for the fuel level sender. and that may be the entry for the retiurn line. Mine leaked its whole tank ( dangerous) rotten hose !

944's made after mid 85 have a plastic tank and a pre-pump. with a plastic tank you have no rust issues. but fitting a different tank could be another issue. the fuel pressure in that is only about 35 but the pump looks the same as the one I got for my ford. a voilvo is higher and also a similar pump

remember a pump does not make pressure, it creates flow. restriction to flow creates pressure, that is set by the fuel pressure regulator and excess fuel free flows back to the tank. so the pump poressure doesnt; set eh fuel rail ressure, the pressure reulator does that,, the pump need sot be adequate for the required presure and flow rate but its not in control of the pressure.

in near the pump is a check valve. it tries ot keep the fuel rail charged with pressure for your next startup. if it leaks back slightly probably not a huge issue. except:

- to check if injectors are not shutting off the system shoudl maintain its pressure, so during that fuel pressure check a leaky check valve looks similar to a leaking injector as fuel pressure won't maintain.

so id clean or replace that if its not with the pump itself to avoid that confusion. there is a fittin near the rear of the engine on the passenger side, its a shrauder valve ( tire valve) but if you unscrew that its just ppe threads, best to use a proper guage but I did try a pressure guage for a compressor and I dpont htink it s a lot different, the right setup has a purge line to purge air .. I dont think it matter much if there is air in there as the guage is sensing pressure, I dont thinkit cres if thats air or fluid. I di get a proper guage and it comes wiht handy fittings. on the porsche or my volvos you need to install a Tee fitting and connect where the fuel line from the pump enters the fuel rail, because ford put a noce fitting you dont need to break the fuel line, which is nicer

I suppose if you are crafty , one could take a bung and the hole it threads into from a 45 gallon drum and use that?

Ha that's 55 in the US ;-)

I replaced a in tank pump in a volvo 240 last summer, the pump was about an inch too long so I just took the whole works and bent it over so it sits on a slant.

either way, the pickup probably has a plastic screen, best renewed. thye may rot, I htink the junk alcohol gas erodes the plastic I found the sameo with the windshild squirter bottle screen, and it also has alcohol,

a carb engine probably has a bit smaller line as with injection its sucking and flowing quite a bit more more fuel than it uses. so larger line is required.

if you are running flat out up a hill you shouldnt see a fuel pressure drop, if you do that could mean restriction.

vacuum from the manifold controls the fuel pressure, as the throttle opens the manifold pressure drops and I believe the system senses that and amps up the fuel pressure, thats what the line ot the pressure regulator does.. If im off on that please correct me. im evidently not always right ;-) for some reason I tend to thinnk of flat out as bing higher vacuum but i dont think that is correct. if you take your foot off the gas and are engine braking that would be higher manifold pressure I believe, so then it needs less fuel

I also think the ECU is firing twice per revolution and changing the open time ( it would be in microseconds) so the fuel rail sees two spurts, this is not timed to the engine timing per cylinder. I think it fiires 3 and then the other three and alternates but again i could stand corrected.

the ECU is looking at the o2 sensor after warmup and thats governing things and as well thqt sensor in the front right of the manifold, its sensing the manifold pressure ( negative pressure)

how the whole sytem works is otherwise a little mysterious to me. the ECU also knows when its warmed up by a temp sensor, there is one just above the waterpump, I htink that one..

there is another temp sensor for the temp guage in the dash.

I replaced my thermostat, that housing was cheap so I ordered one I was glad I did it was usable but quite corroded. some seem ot be suggesting the new thermostats are not accurate so you could b=oil it on the stove with a thermomenter and see when it actually does open.

whan I throw my van in revers it can someties stall, I believe the ECU also knows when you are in reverse, why It needs that Im not sure but I think there is some connection..and others could clarify or correct me on that one.

I looked atht eh ECU in my 88 van. on the circuoit board I could see a slight stain under the electrolytic capacitors, you can clip the leads about 1/ 16 or so above the board and pull the cap off leaving little stubs then wind the new cap leads around a pin to make a shape like a spring then solder and crimp.. if you wan to open it further youll break the heat putty to access the solder side of the board.. in my case i accidentally clipped the corner off a transistor and oredered rebuilt one but if you feel up to it you could likely just rreplace those 3 or so capacitors. they were rated for 16 working volts, note the polarity and take pics, and the value in microfarads. dont put them backwards. it matters, the line on the cap identifies the negative lead.

an electrolytic cap that has leaked its internal oil , its probably PCB's ,, its a physical sign the cap has crapped out, they could also be bulged out what I noted was looking at the board beneath each cap and look close for a stain or maybe a bit lighter color due to the fluiid..

if you do clip them as I suggested wear glasses the things can squirt in yout eye and whatever it is Id be cautious of that.

you can probably check them in place with an ESR meter.

I;d just just replace, they are only a buck or so . careful of any static shock to the ECU I'll normally ground myself with a wrist strap if I touch a board, if you happen to dischage static it can blow a microchip or E-prom. or whatever those little parts with all the tiny legs are called ;-)

Since you are doing a lot of switching stuff around it might be a bad time to try to repair and ECU as you dont need more confusion or several reasons for a no start all at once.. opening it and getting a visual might be ok.

I may stand corrected on a few things here so just speak up if I've gone off track. and said stuff thats incorrect.

if the tank pump goes bad, then the car ruins fine until it reaches about half full then she has issues. it wont run at all without the main piump.

I guess the right way would be to use something close to the OEM setup with the pre pump in the tank and yea you need a return line for FI. But it is likely possible to cheat and pull fuel from the bottom.

I think the reasoning is a rubber line can go rotten and leak the whole tank so it was revised for safety reasons. and both would use quite good quality materials for fuel lines. I dont know but I suspect that it was a later safety requirement. maybe mid 85 or so. ?

I have a early 85 porshe 944 it takes fuel from the bottom , that has no in tanlk pump. but it does have an opening for the fuel level sender. and that may be the entry for the retiurn line. Mine leaked its whole tank ( dangerous) rotten hose !

944's made after mid 85 have a plastic tank and a pre-pump. with a plastic tank you have no rust issues. but fitting a different tank could be another issue. the fuel pressure in that is only about 35 but the pump looks the same as the one I got for my ford. a voilvo is higher and also a similar pump

remember a pump does not make pressure, it creates flow. restriction to flow creates pressure, that is set by the fuel pressure regulator and excess fuel free flows back to the tank. so the pump poressure doesnt; set eh fuel rail ressure, the pressure reulator does that,, the pump need sot be adequate for the required presure and flow rate but its not in control of the pressure.

in near the pump is a check valve. it tries ot keep the fuel rail charged with pressure for your next startup. if it leaks back slightly probably not a huge issue. except:

- to check if injectors are not shutting off the system shoudl maintain its pressure, so during that fuel pressure check a leaky check valve looks similar to a leaking injector as fuel pressure won't maintain.

so id clean or replace that if its not with the pump itself to avoid that confusion. there is a fittin near the rear of the engine on the passenger side, its a shrauder valve ( tire valve) but if you unscrew that its just ppe threads, best to use a proper guage but I did try a pressure guage for a compressor and I dpont htink it s a lot different, the right setup has a purge line to purge air .. I dont think it matter much if there is air in there as the guage is sensing pressure, I dont thinkit cres if thats air or fluid. I di get a proper guage and it comes wiht handy fittings. on the porsche or my volvos you need to install a Tee fitting and connect where the fuel line from the pump enters the fuel rail, because ford put a noce fitting you dont need to break the fuel line, which is nicer

I suppose if you are crafty , one could take a bung and the hole it threads into from a 45 gallon drum and use that?

Ha that's 55 in the US ;-)

I replaced a in tank pump in a volvo 240 last summer, the pump was about an inch too long so I just took the whole works and bent it over so it sits on a slant.

either way, the pickup probably has a plastic screen, best renewed. thye may rot, I htink the junk alcohol gas erodes the plastic I found the sameo with the windshild squirter bottle screen, and it also has alcohol,

a carb engine probably has a bit smaller line as with injection its sucking and flowing quite a bit more more fuel than it uses. so larger line is required.

if you are running flat out up a hill you shouldnt see a fuel pressure drop, if you do that could mean restriction.

vacuum from the manifold controls the fuel pressure, as the throttle opens the manifold pressure drops and I believe the system senses that and amps up the fuel pressure, thats what the line ot the pressure regulator does.. If im off on that please correct me. im evidently not always right ;-) for some reason I tend to thinnk of flat out as bing higher vacuum but i dont think that is correct. if you take your foot off the gas and are engine braking that would be higher manifold pressure I believe, so then it needs less fuel

I also think the ECU is firing twice per revolution and changing the open time ( it would be in microseconds) so the fuel rail sees two spurts, this is not timed to the engine timing per cylinder. I think it fiires 3 and then the other three and alternates but again i could stand corrected.

the ECU is looking at the o2 sensor after warmup and thats governing things and as well thqt sensor in the front right of the manifold, its sensing the manifold pressure ( negative pressure)

how the whole sytem works is otherwise a little mysterious to me. the ECU also knows when its warmed up by a temp sensor, there is one just above the waterpump, I htink that one..

there is another temp sensor for the temp guage in the dash.

I replaced my thermostat, that housing was cheap so I ordered one I was glad I did it was usable but quite corroded. some seem ot be suggesting the new thermostats are not accurate so you could b=oil it on the stove with a thermomenter and see when it actually does open.

whan I throw my van in revers it can someties stall, I believe the ECU also knows when you are in reverse, why It needs that Im not sure but I think there is some connection..and others could clarify or correct me on that one.

I looked atht eh ECU in my 88 van. on the circuoit board I could see a slight stain under the electrolytic capacitors, you can clip the leads about 1/ 16 or so above the board and pull the cap off leaving little stubs then wind the new cap leads around a pin to make a shape like a spring then solder and crimp.. if you wan to open it further youll break the heat putty to access the solder side of the board.. in my case i accidentally clipped the corner off a transistor and oredered rebuilt one but if you feel up to it you could likely just rreplace those 3 or so capacitors. they were rated for 16 working volts, note the polarity and take pics, and the value in microfarads. dont put them backwards. it matters, the line on the cap identifies the negative lead.

an electrolytic cap that has leaked its internal oil , its probably PCB's ,, its a physical sign the cap has crapped out, they could also be bulged out what I noted was looking at the board beneath each cap and look close for a stain or maybe a bit lighter color due to the fluiid..

if you do clip them as I suggested wear glasses the things can squirt in yout eye and whatever it is Id be cautious of that.

you can probably check them in place with an ESR meter.

I;d just just replace, they are only a buck or so . careful of any static shock to the ECU I'll normally ground myself with a wrist strap if I touch a board, if you happen to dischage static it can blow a microchip or E-prom. or whatever those little parts with all the tiny legs are called ;-)

Since you are doing a lot of switching stuff around it might be a bad time to try to repair and ECU as you dont need more confusion or several reasons for a no start all at once.. opening it and getting a visual might be ok.

I may stand corrected on a few things here so just speak up if I've gone off track. and said stuff thats incorrect.

Last edited:

Only one pump and it's in the tank. I'll likely use an aftermarket early mustang tank that will accept a submerged pump. I don't feel like cutting up a tank to add baffles etc for injection service.something close to the OEM setup with the pre pump

I can get weld bungs for about $3. There are lots of items avail to modify the tank and the system I just don't want to try to add baffles.bung and the hole it threads into from a 45 gallon drum

Regarding your comments on how the injection works, I have a bunch of learning to do. I've done it before on a Throttle body GM and it wasn't too bad. But I had the programming done for me. We had a "no start" caused by not having the stock steering column in place. New chip fixed it. The ford is different and I plan on doing the programming through a quarter horse add on board and a lap top. I'm feeling pretty comfortable that I'll get through it and have some fun doing it. I'll check back to your comments once I've learned a bit more.

Thank you!

philford

Famous Member

just keep in mind im not necessarily that smart or an experienced ford guy, I just ttried to reiterate some stuff that Ive been working to understand better.. there are people in here with a wealth of ford L6 experienceOnly one pump and it's in the tank. I'll likely use an aftermarket early mustang tank that will accept a submerged pump. I don't feel like cutting up a tank to add baffles etc for injection service.

I can get weld bungs for about $3. There are lots of items avail to modify the tank and the system I just don't want to try to add baffles.

Regarding your comments on how the injection works, I have a bunch of learning to do. I've done it before on a Throttle body GM and it wasn't too bad. But I had the programming done for me. We had a "no start" caused by not having the stock steering column in place. New chip fixed it. The ford is different and I plan on doing the programming through a quarter horse add on board and a lap top. I'm feeling pretty comfortable that I'll get through it and have some fun doing it. I'll check back to your comments once I've learned a bit more.

Thank you!

In case someone reviews this in the future I'll add some items as I find them. Today it was wire looms. Nice pieces in the van for organizing wires in the next van. Also the windshield washer tank and pump. And now I'm wondering if it could be used for water injection in the future...

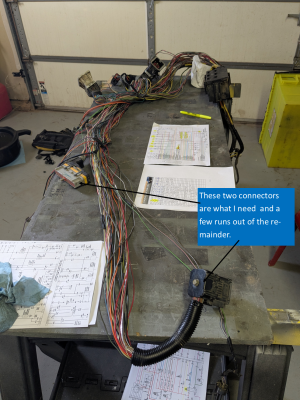

I'm not going to lie. A $600 aftermarket wiring harness is looking better and better.....What you are looking at doesn't include another 10' or so of misc wiring harness legs and god knows how much that is still buried in engine tunnel.

Still need to figure out how to separate out what I actually need. I suspect that the van harness, like everything else on the van is more complicated than on a truck or a car. But damn the routing couldn't be more obnoxious. Any shortcuts would be appreciated.

And it looks like the cruise control talks to the cpu. Should I keep it? A little weird on a gasser but I like the price.

Oh yea, any one need a 170 and a 3 speed.

Thanks in advance

Bart

Still need to figure out how to separate out what I actually need. I suspect that the van harness, like everything else on the van is more complicated than on a truck or a car. But damn the routing couldn't be more obnoxious. Any shortcuts would be appreciated.

And it looks like the cruise control talks to the cpu. Should I keep it? A little weird on a gasser but I like the price.

Oh yea, any one need a 170 and a 3 speed.

Thanks in advance

Bart

Ok, you opened the door and I didn't want to clutter your original post. Any links to good primers on how to separate out what you need from a wiring harness? I've printed out your efi swap page and I'm going to use the list to try and trace wiring.If anyone has any questions don't hesitate to post back and I'll try to respond as soon as possible although I don't frequent here often.

Thanks in advance.

Bart

Viperwolf1

New member

Thank youHere are my references from when I installed a 300 into an early Bronco.

This is a simple in-tank pump performance upgrade. https://www.highflowfuel.com/fuel-pump-assembly-performance-qfs-a27hv-qfs. They have a cheaper 255lph version as well. The 340lph I linked is ready for e85 so is a more durable unit.

I have also bought the matching cheap autozone pump assemblies and replaced the pump inside with a high flow unit.

I have also bought the matching cheap autozone pump assemblies and replaced the pump inside with a high flow unit.

Last edited:

Great timing. I've been looking at pumps and tanks. ThanksThis is a simple in-tank pump performance upgrade.

Help.....

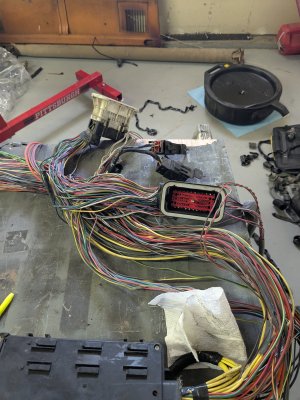

I'm not lost but I'm looking for a better place to start. I have most of the injector harness separated out (it was easy as it was somewhat separate from the factory main harness). What I have to to next is separate out the ecu wiring and a few other components from the main harness. Turns out that on a van the main harness is a 20' bundle of wires with multiple branches. Much more involved than any guideline I'm following and on top of it I cannot find a chart with accurate color coding for the 95 van.

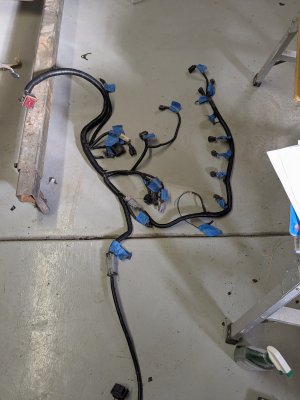

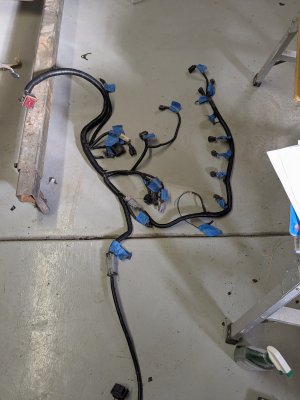

This first picture is the harness legs for most of the sensors and the injectors. Relatively clean. I just need to strip out vacuum controls.

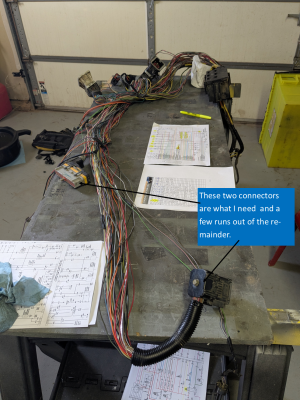

The 2nd picture is the nightmare.

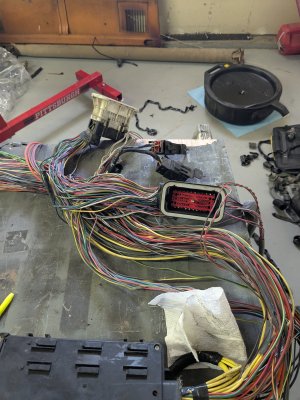

This is a closer look at what I need to sort through....

Anyone have a clue if there are any large chunks I can remove before I start stripping out the few things I need to keep?

Thanks in advance

Bart

I'm not lost but I'm looking for a better place to start. I have most of the injector harness separated out (it was easy as it was somewhat separate from the factory main harness). What I have to to next is separate out the ecu wiring and a few other components from the main harness. Turns out that on a van the main harness is a 20' bundle of wires with multiple branches. Much more involved than any guideline I'm following and on top of it I cannot find a chart with accurate color coding for the 95 van.

This first picture is the harness legs for most of the sensors and the injectors. Relatively clean. I just need to strip out vacuum controls.

The 2nd picture is the nightmare.

This is a closer look at what I need to sort through....

Anyone have a clue if there are any large chunks I can remove before I start stripping out the few things I need to keep?

Thanks in advance

Bart

Just a heads up, your docs are getting me through this! Thank youHere are my references from when I installed a 300 into an early Bronco.

If you are going back with the factory ECU, (with tune of course)I would keep everything intact as it won't have any effect other than it bothers you. Simply being as you may want to revisit a removed component later; and it is of little to no hinderance

There are a couple extra things I'm gonna keep but I need to lose some of the engine compartment harness. It's 15'+ of wire bundle 1.5" in diameter. It's freaking hugeIf you are going back with the factory ECU, (with tune of course)I would keep everything intact as it won't have any effect other than it bothers you. Simply being as you may want to revisit a removed component later; and it is of little to no hinderance

Last edited:

I've edited my intro. Bottom line is that I advise against using the harness from a 95/96, especially a van. The harness is substantially different from basically all of the walk throughs I found. I believe it can be done and I'm continuing to pursue it but what a mess!

They're almost all different in my frustrated efforts to find a simple way to return my '90 to EFI. It's been carb for over a decade, never been as good as factory EFI. I've gotten several harness- '91, '93, '89- were not the same.I've edited my intro. Bottom line is that I advise against using the harness from a 95/96, especially a van. The harness is substantially different from basically all of the walk throughs I found. I believe it can be done and I'm continuing to pursue it but what a mess!

Similar threads

All Small Six

Generator to 1G Alternator Conversion

- Replies

- 18

- Views

- 409

- Replies

- 8

- Views

- 464

All Small Six

I have a few questions about the 250ci

- Replies

- 8

- Views

- 2K

- Replies

- 16

- Views

- 8K