Question for the community:

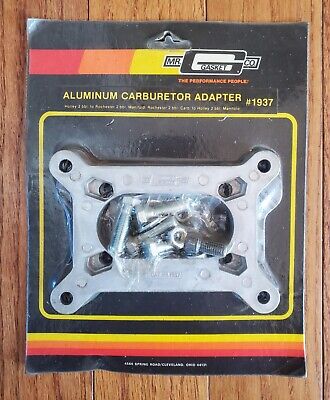

Wondering if you have a rec for an adaptor that would fit the Holley 350 to a '66 200 i6 stock engine? Also wondering if you’ve got an air filter rec that would avoid clearance issues, as well as a throttle linkage kit that’d work for this.

Any thoughts are welcome!

Here are the options I've found. Am I on the right track?

www.vintageinlines.com

www.vintageinlines.com

Thanks!

Jack

Wondering if you have a rec for an adaptor that would fit the Holley 350 to a '66 200 i6 stock engine? Also wondering if you’ve got an air filter rec that would avoid clearance issues, as well as a throttle linkage kit that’d work for this.

Any thoughts are welcome!

Here are the options I've found. Am I on the right track?

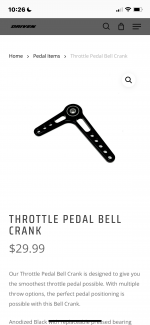

Autolite/Holley 1V-2V Adapter - Small Log | Vintage Inlines

This billet adaptor is used to install any Autolite, Holley, or MotorCraft 2V carb on a stock SMALL LOG cylinder head with a 1.5" carb bore. The adapter comes with a custom billet insert, which improves air flow and horse power, and two stainless steel Allen head cap screws for mounting (carb...

Thanks!

Jack