I have a 69 mustang with a 6-200. Looking for input here.

I am looking for input on a build. Hot street some autocross just fun. No stop and go traffic.

I already have a Clifford long tube 3 into 1 x2 header.

I am looking to get a large log head. Bigger valves, ported, new seals and springs, hardened seats.

Next was new pistons and a fresh bore.

My questions start here. For better flow and fuel delivery 3X1 or a 2v conversion?

Compression range to shoot for?

I want a rough and rowdy cam and exhaust note. Not the slow chop like a v8 but more of a higher rpm idle

Would a 6 into one header be better vs my 3 into one x2 header.

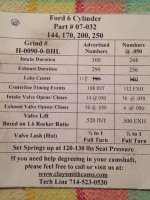

And in another build on the turbo page a member is running this cam and it sounds great but wasn’t working for a boosted application. How about for NA?

I am looking for input on a build. Hot street some autocross just fun. No stop and go traffic.

I already have a Clifford long tube 3 into 1 x2 header.

I am looking to get a large log head. Bigger valves, ported, new seals and springs, hardened seats.

Next was new pistons and a fresh bore.

My questions start here. For better flow and fuel delivery 3X1 or a 2v conversion?

Compression range to shoot for?

I want a rough and rowdy cam and exhaust note. Not the slow chop like a v8 but more of a higher rpm idle

Would a 6 into one header be better vs my 3 into one x2 header.

And in another build on the turbo page a member is running this cam and it sounds great but wasn’t working for a boosted application. How about for NA?