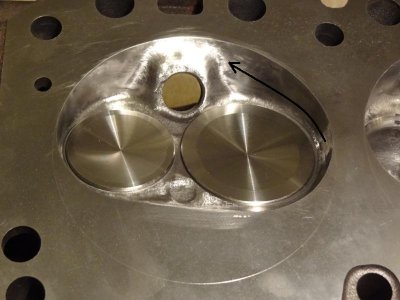

No particular reason, the head is off the block right now for bigger intake valves and I thought I could try to improve my quench distance.

Tighter quench means more compression and I was wondering if the combination could run safely on 91. Gas prices are only going up, so I would prefer using the 91 over the 94...

Tighter quench means more compression and I was wondering if the combination could run safely on 91. Gas prices are only going up, so I would prefer using the 91 over the 94...