Okay, here is my "uber pwnage" combination. Its based on an idea I floated in 2002 with an X-flow head, but it'll be better with the D8 or Classic Inline head as its non cross flow, and allows space for a killer blower.I discussed in I'm Gonna Blow my Budget post in the hardcore formum many moons ago.

Grab a 250 block and grimnd up two custom 250 cranks. Both should be stock 250 US cranks which are offset grind it to 1.676" jounal diameter, and index the stroke to 3.46". Then reweld the crank up to 2.126", and cut the crank back to a 15 thou fillet radius. Add 6.21" Ford 300/4.9 forged rods, and have the gudgeon/little ends replaced with the Chevy 0.927" bush.

I used used old TRW 305 V8 /229 V6 forged pistons (there were three part numbers to choose from, and they are around if you know where to look), or perhaps the KB 101 22 cc, KB 145, 12 cc, (Keith Black / Silvolite hypereutectic) , 22cc to down to 12.1 cc. The deck is 1.561 now quoted but there used to be a 1.531" deck version used to be available. They can be skimed to suit the 250 block, at 1.561, they will hit the squench area unless you run a 60 thou gasket

Here it is compared to a 258 Jeep piston

Then run a D8 iron head with three Holley 4412 carbs using a welded adaptor like the Falcon Six Handbook suggests, duplicated three times.

Use all there Falcon Six handbook tricks on airflow management, and go for the bigger SI valves Classic inline supply.

Then create a bleed back carb system like David Vizard suggested on page 167 of Reworking Fords SOHC engine. That uses a good mechanical fuel pump to deliver fuel to the carbs, and no float bowls, but a special standpipe made of bunday tube . Fuel surge is eliminated by fuel cell foam, a requirement for stock fuel tanks in most racing classes. The foam is piut into the float bowl, and the stand pipe sucks the bowl dry. You can runa car on a 45 degree angle using this combination. The float bowl is sucked dry by a Facet or Carter electric fuel pump, and float level is controlled by a Holley main jet of varying size controlling the incomming fuel. No injection, no calibration issues, just simple math to make it work

Take each carb, and hone out the 1.375" venturi to anything bigger than 1.4375" using a woodern broom handle mounted on a power drill, and 3m fine grit sand paper. Hand linish the correct venturi taper, and block off the power valve using a stock Holley PV eliminator kit. Calibrate it like three DCOE 42 Webers, and get a cam which has power at 5500rpm, revs to 6000 rpm, and is about 290 degrees, 225 degrees at 50 thou, and has a lift of about 510 at the valve with 1.75:1 FE roller rockers.

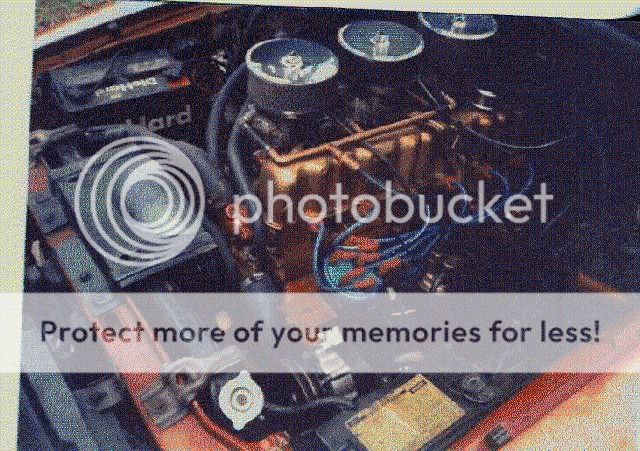

Care of Jack Collins years old triple 1-bbl 250 he helped make. Its got had made triple adaptor, handwelded dual out iron header. The general look of the engine will be like this, but you'll have to help find potential owners for some custom Fox headers that Mike has been looking at for some time

Your power should get to 300 hp at 5500 rpm, and about 300 lb-ft at 3200 rpm. Set CR to 8.6:1, a perfect 0 deck engine with a 200 thou trench in the piston which should be great for spark travel. Use a waste spark igintion system from a Ford Explorer 4.0.

From

http://falconperformance.sundog.net/compcalculator.asp

Input Values:

Number Of Cylinders 6

Bore Diameter [inches] 3.736

Stroke Length [inches] 3.46

Combustion Chamber Volume [cubic centimeters] 62

Head Gasket Compressed Thickness [inches] 25 thou

Head Gasket Bore Diameter [inches] 3.81"

Piston To Deck Clearance [inches] 0.002"

Select Piston Type Dished

Dish/Valve Relief/Dome Volume [positive cubic centimeters] 12.1cc

Volumetric Efficiency: 85%

RPM: 5500

Results: (Based on single carb, log head, no cam mods, no indpendent runner tuning )

Displacement, [cubic inches] 228

Displacement, [liters] 3.7

Static compression ratio 8.9:1

Cubic Feet per Minute required @ 5500 rpm, [cfm] 309

Estimated Horsepower @ 5500 rpm

Assumes altitude of sealevel, barometric pressure of 14.696 and 60° air supply to carburator 172

Independent runners, wild cam, the right carb size and jetting, there is better than a 50% boost in this kind of optimisation

Once you've got that running with a close ratio rip shifted T5 gearbox and a 3.45:1 diff, you can then bolt a nice big 284 cid per revolution 4/71 blower on the side. I've got a Wade 208 cid per revolution blower which will do the same thing.

The engine should then see 500 hp at 5500rpm, and 500 lb-ft with 13 pounds boost and no intercooler.

This was my original design concept for my X-flow 228 cube engine in the early Naughtees. I'd like to think I'll do it once I've got my other projects finished.