I have this 220 six with the Duraspark II and a card one distributer. The carb is an aftermarket Autolite knockoff. I am drawing vacuum off the intake manifold port. Set the timing dead on 12 degrees b t c. When I attach vacuum line it jumps up about 10 degree or 22 b t d c. Idles fairly well but stalls on acceleration. Hooked up vacuum gauge. Reads about 12” but then drops on acceleration. See video. Do I need to recurve? Cardone rep. says timing shouldadvance maybe 5 degrees when I put vacuum on and may be 15 degrees at 2,000 rpm. Ideas? In process of plugging three ports.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six Duraspark conversion with some headache

- Thread starter adobejoe

- Start date

This relates to all small sixes

Sorry but this is pretty much normal behavior drawing advance off the manifold vacuum. There is high manifold vacuum (advance) at idle, low manifold vacuum (advance) at heavy throttle, the opposite of what that distributor needs/ gets from ported vacuum. Unfortunately with that SCV carb you don’t have ported vacuum available without modifications. I know some people say they run manifold vacuum advance just fine on their engine but there is a reason Ford ran SCV carbs with loadamatic distributors and non-SCV carbs with mechanical/ported vacuum advance distributors, mixing those parts together usually creates problems like this. I’m not sure if your “Autolite knockoff” carb will respond to the SCV mods documented on this site like OEM, but it’s worth a shot in my opinion to try and convert it to ported vacuum and use that port.

PSIG

Famous Member

Your issues could be a combination of effects, from idle mixture tuning, accel circuit tuning, timing and timing change rate (some vac advance canisters are slower and cause bucking or stalling). Also check your distributor advance moving parts are lightly lubricated, and the felt oiling wick in the top-center of the shaft gets several drops of engine oil in it (standard maintenance item  ) in-case friction is slowing it down. The rotor should spring one way, and solidly snap back when released. Use a hand-vac pump to check for vac canister operation, and that it holds vacuum without leaks. Today, "new" does not mean "good".

) in-case friction is slowing it down. The rotor should spring one way, and solidly snap back when released. Use a hand-vac pump to check for vac canister operation, and that it holds vacuum without leaks. Today, "new" does not mean "good".

Assuming all that made insufficient change; if it were me (and it used to run "fine"), I'd re-tune the idle mix and warm idle rpm, drop the base timing to ±6°BTC (no vac), then reconnect vac and test for effects of idle, accel, and low-speeds. Do NOT run high speed or loads while testing idle and accel - the distributor curves are not ready for that.

If you find improvement, you can do more testing to find the sweet spot. Once you know the combo it likes, configure your distributor to apply those numbers (ask if you don't know how). Let us know how you proceed.

Assuming all that made insufficient change; if it were me (and it used to run "fine"), I'd re-tune the idle mix and warm idle rpm, drop the base timing to ±6°BTC (no vac), then reconnect vac and test for effects of idle, accel, and low-speeds. Do NOT run high speed or loads while testing idle and accel - the distributor curves are not ready for that.

If you find improvement, you can do more testing to find the sweet spot. Once you know the combo it likes, configure your distributor to apply those numbers (ask if you don't know how). Let us know how you proceed.

Adobejoe, you have several problems.

First is the advance curve of your remanufactured DS11 & the amount of vacuum advance.

Second a stock engine should run with ported vacuum.

Third you have a SCV carburtor so you can't run ported advance.

I need to recurve your DS11 & convert you SCV carb so you can run ported vacuum.

Or you can purchase one of my DS11's.

Contact me. billythedistributorman@live.com Provide your phone number & the best time to call. Bill wsa111

First is the advance curve of your remanufactured DS11 & the amount of vacuum advance.

Second a stock engine should run with ported vacuum.

Third you have a SCV carburtor so you can't run ported advance.

I need to recurve your DS11 & convert you SCV carb so you can run ported vacuum.

Or you can purchase one of my DS11's.

Contact me. billythedistributorman@live.com Provide your phone number & the best time to call. Bill wsa111

Last edited:

PSIG

Famous Member

I watched your video, and it looks mostly "normal" for idle vacuum advance timing (±10° vac advance at ±12"Hg), but two things jump-out that are worth looking into before too many assumptions are made. First is only 12"Hg at idle.  Idle vacuum should be more than that, for a stock-ish engine of this type. Second, revving will see vacuum drop like a rock initially, but should recover to high vac holding higher rpm. Yours does not appear to.

Idle vacuum should be more than that, for a stock-ish engine of this type. Second, revving will see vacuum drop like a rock initially, but should recover to high vac holding higher rpm. Yours does not appear to.

One approach to checking this is to disconnect the vacuum canister, and repeat the exercise, re-setting idle rpm and do your revving as before. If the engine has greater idle vac, and vac recovers well during light rev-and-hold - you have a vac canister issue. If the symptoms are relatively maintained (continuing low vac at idle and poor vac recovery after initial throttle), then you have a mechanical advance, carb tuning, exhaust, or timing mark issue.

As you (and we) have no idea what Cardone did to it before you got it, we can side-step the possible mechanical issues by setting the timing at max advance, instead of curb idle advance. Max advance is a known and controllable value, of perhaps 36° all-in. If we rev (no vac) to the point all advance is in, and set timing to 36°, then we can let it idle-down and see what Cardone did with the timing curve. This importantly maintains high-speed and high-load timing for engine safety, and the remainder of the timing curve - no matter what the less-dangerous low-load is doing.

This importantly maintains high-speed and high-load timing for engine safety, and the remainder of the timing curve - no matter what the less-dangerous low-load is doing.

I'm not trying to make work for you, but the issue needs solving in any case, and this is one way to approach it without added expense. Note that engine idle timing was historically always very advanced (maximum brake torque timing) until (mostly) emissions pushed the factories to ported vac. It should be capable of great operation on manifold or ported vac, if everything else is as it should be.

Even today, many engines that are not under emissions requirements use manifold vacuum for advance, for efficient and effective timing control. That's a nice way of saying that those claiming only manifold or only ported vac is OK, are misinformed. They are two different approaches for different reasons and goals. While your new distributor was originally set-up for ported vac, it can run well either way, when set-up and operating properly. Your SCV/LOM carb is currently forcing you to only manifold vac, but either the distributor or the carb can be modified for good function, and both will need some tuning. Which path do you wish to travel?

They are two different approaches for different reasons and goals. While your new distributor was originally set-up for ported vac, it can run well either way, when set-up and operating properly. Your SCV/LOM carb is currently forcing you to only manifold vac, but either the distributor or the carb can be modified for good function, and both will need some tuning. Which path do you wish to travel?

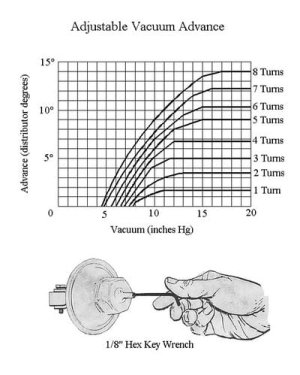

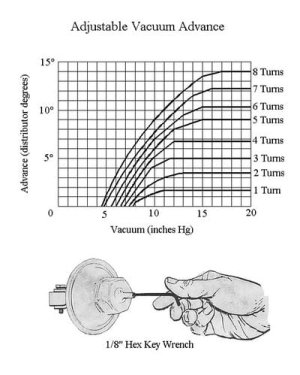

Below is an example vacuum advance chart for a generic adjustable vacuum canister (many curves and ranges available), to show some of the effects available at 12"Hg idle vacuum. With a typical Ford I6 10-20° max vacuum advance, most of it would be applied at 12"Hg. Not sure where the Cardone tech got 5°, but then again, we don't know how it was set-up by them.

One approach to checking this is to disconnect the vacuum canister, and repeat the exercise, re-setting idle rpm and do your revving as before. If the engine has greater idle vac, and vac recovers well during light rev-and-hold - you have a vac canister issue. If the symptoms are relatively maintained (continuing low vac at idle and poor vac recovery after initial throttle), then you have a mechanical advance, carb tuning, exhaust, or timing mark issue.

As you (and we) have no idea what Cardone did to it before you got it, we can side-step the possible mechanical issues by setting the timing at max advance, instead of curb idle advance. Max advance is a known and controllable value, of perhaps 36° all-in. If we rev (no vac) to the point all advance is in, and set timing to 36°, then we can let it idle-down and see what Cardone did with the timing curve.

I'm not trying to make work for you, but the issue needs solving in any case, and this is one way to approach it without added expense. Note that engine idle timing was historically always very advanced (maximum brake torque timing) until (mostly) emissions pushed the factories to ported vac. It should be capable of great operation on manifold or ported vac, if everything else is as it should be.

Even today, many engines that are not under emissions requirements use manifold vacuum for advance, for efficient and effective timing control. That's a nice way of saying that those claiming only manifold or only ported vac is OK, are misinformed.

Below is an example vacuum advance chart for a generic adjustable vacuum canister (many curves and ranges available), to show some of the effects available at 12"Hg idle vacuum. With a typical Ford I6 10-20° max vacuum advance, most of it would be applied at 12"Hg. Not sure where the Cardone tech got 5°, but then again, we don't know how it was set-up by them.

PSIG

Famous Member

Agreed. My graphic was to demonstrate typical vac advance function, and how most of the advance will likely be applied even at 12"Hg idle, making the Cardone statement confusing. For reader awareness - most vac advance canisters are adjustable, some with hex wrenches, some with springs and spacers, a few not at all. Those with a "hex" snout (like @wsa111's image), or thinner version of a hex (Ford type below), are typically adjustable in some way.You vacuum advance may not be adjustable.

Show us a photo of your vacuum advance canister.

Is it shiny or is one half one finish & the other half a different finish?

https://fordsix.com/threads/135-00-...or-a-stock-or-slightly-modified-engine.85478/ This is not adjustable.

Is it shiny or is one half one finish & the other half a different finish?

https://fordsix.com/threads/135-00-...or-a-stock-or-slightly-modified-engine.85478/ This is not adjustable.

My vacuum gage was not calibrated to zero. I readjusted zero set point Now it track spot on 17” at idle. See video. I tried timing light with vac line off and sealed. Spot on 12 d b t d c. I wanted to see the mechanical advance of distributer. It is electronic, no points, and connected to a Duraspark 2. As I wrapped out rpm’s it only advanced 2-3 degrees. II wonder if distributer defective? Surely it should advance more on the mechanical part? When I reattach vacuum line even at 1000 rpm’s it advanced about ten degrees.

View attachment IMG_6891.MOV

View attachment IMG_6891.MOV

Switched vacuum to take off venturi (port?). Point more in throat of carb. I guess that is “port”. Maybe someone can verify? At idle vacuum is zero” as opposed to 17” when taken off manifold. When wrapped out (WOT) it would only go up to maybe 8 inches. BUT seems to idle better and took it on spin and seems much smoother even up around 2,500 rpm. So i will check it with timing light tonight. This seems a marked improvement. See video

Attachments

Ran timing light. Most advanced is maybe 3-4 deg above set at 12 deg so maybe 15-16 degree advance at 2500 rpm. I am wondering this CARDONE is a dud? Why is it this lame? Surely one should expect better. “PSIG”you out there. Anyone know how to adjust the mechanical advance or maybe I return to manufacturer? Ideas?

Attachments

That's way off. The mechanical side should advance in the 25* neighborhood by 3000 rpm. your 17" idle vacuum is good, and no vacuum on the ported vacuum at idle is correct. The vacuum advance is doing it's job. At this point, the centrifugal advance needs to be addressed. With the cap off, take hold of the rotor and attempt to twist it in the direction it rotates when running. The tip should give modest resistance and move at least 1/2". If it's way stiff or moves less, this confirms the centrifugal advance has a malfunction.Ran timing light. Most advanced is maybe 3-4 deg above set at 12 deg so maybe 15-16 degree advance at 2500 rpm. I am wondering this CARDONE is a dud? Why is it this lame? Surely one should expect better. “PSIG”you out there. Anyone know how to adjust the mechanical advance or maybe I return to manufacturer? Ideas?

I need to finish the JimG carb modification,,,,drill out a new vacuum port slightly above the existing which I seal ( the one shown in blue). That way I get some vacuum advance but not the excessive 10 deg taking off the intake manifold.

Delete SCV on 1100 Autolite for Ported Vacuum

Here are the instructions to delete the SCV on a Autolite 1100 & convert the vacuum port to ported vacuum. You need a #36 drill bit to drill a shallow hole to just the depth of the 6-32" brass set screw. You will use 3 of these set screws. Tap only the orifices circled in red there are...

TrickSix

Famous Member

Cardone = car done, it's right there in the name! From the limited spec sheets I have seen the single vacuum canister versions of these usually have a more aggressive advance curve than the double vacuum cans. If you're patient enough to search a little while you can usually find them cheaper than this too. My car runs great with a similar stock distributor on manifold vacuum and a capped vacuum port SCV 1100. It will take me a few more years to get enough miles on it to worry about changing the points. You've spent enough time on your new-fangled electronic gadget to change some points several times over! But I'm a Luddite pneumatic dust distribution device, sometimes new ways work, and I'm not a fair judge for them...Ideas?

https://www.ebay.com/itm/2850356283...uid=yPAA4oA3Qxu&widget_ver=artemis&media=COPY

Frank, thanks on input. The distributer seems to rotate barely 1/2 inch, maybe less. I need to complete the Jim G mod so I can get some vacuum through that upper port. It is a little unclear where exactly that hole needs to be drilled into the carb throat. Is it the same access the vacuum Attaches? See picture. Maybe where the needle nose pliars point? I have three of these Autolite carbs, all with that scv valve. So if I butcher one it not the end of the world., but I would like to get it right. I also just not to excited about taking vacuum off the manifold. I am getting zero vacuum through the port at top pic two. Unless I have some other vacuum leak, adapter plate or gaskets, I am a bit baffled why no vacuum as shown. Was thanks for link. Trick Six. Noted. Gotta say, guys, I was strongly suggested to do this by BUBBA who I am sad to hear has passed. I ordered and paid for a distributer last august from a company Pxxxxxx Dxxxxxx. By February they still had not started so what would you do? Wsa111 I am sure you know what you are doing. Question; how many inches should that gauge show at say, 2000 rpm?

Attachments

Looking at JimG mod and notes helps. Looks like I need to remove the brass plug/seal at needle nose, then drill another hole, paper clip diameter? Slightly above old hole and seal existing hole with job weld. Then find another seal/plug. Also seal Venturi hole at current vacuum. Then that creates that internal passage. I need to start getting some useable vacuum, starting at idle, before I can figure out this mechanical issue on the distributer. Bottom line, I want to get so idles about 600 rpm with timing at 12 dbtdc and wraps out to say 2500 rpm at timing 35 dbtdc. That should give me power and economy on this rebuilt six.

So I drilled out the small brass plug and discovered that when it was originally inserted (pushed) it appeared to block the passage up into the scv cavity and also to the top channel where the carb half splits no wonder no vacuum. See pic there is very little room to drill a second hole into throat of carb where paper clip shows but I can try. Will try sealing with in weld instead of set screws as JimG outline. Then test with hand vac gage to make sure I have good ported vacuum route. I have a pin gage set and can drill whatever size new hole into throat. Start small I guess and see how it behaves.

Attachments

Similar threads

- Replies

- 50

- Views

- 17K

- Replies

- 17

- Views

- 5K

A

- Replies

- 3

- Views

- 1K

A