edgewood bronco

Well-known member

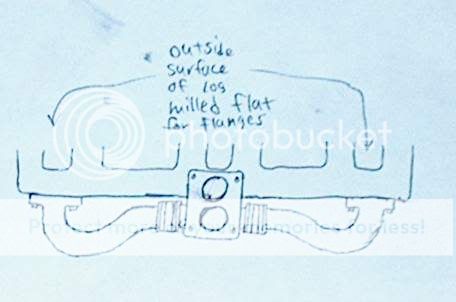

I've started porting a head for my bronco! So far, I'm eight hours in. About 30 minutes of that was straightening the burr when I dropped the drill and bent it 5 minutes in to my day... Ugh...

I've basically worn out a carbide burr (eastwood part no. 11951). My forearms are sore, I've got a stiff neck, and I'm absolutely filthy - I look like a raccoon from the dust rings on my face due to goggles and a respirator - but what fun to open up one of these heads and imagine how much better it's going to breathe. So far, I've just done the inside passages - not the combustion chamber, trying to smooth things out and get rid of some of the restrictions as best as I can.

I've got a question concerning the combustion chamber side:

How much do I take out from the wall on the deepest part of the combustion chamber? Obviously, more clearance between the open valve and the wall will help it will breathe better, but it also reduces compression ratio. Can anybody with experience in this area offer some advice?

Also, What kind of burrs and other abrasives do you recommend? I'm fairly pleased with the above - mentioned burr, but was wondering if others had other suggestions and sources.

Thanks!

I've basically worn out a carbide burr (eastwood part no. 11951). My forearms are sore, I've got a stiff neck, and I'm absolutely filthy - I look like a raccoon from the dust rings on my face due to goggles and a respirator - but what fun to open up one of these heads and imagine how much better it's going to breathe. So far, I've just done the inside passages - not the combustion chamber, trying to smooth things out and get rid of some of the restrictions as best as I can.

I've got a question concerning the combustion chamber side:

How much do I take out from the wall on the deepest part of the combustion chamber? Obviously, more clearance between the open valve and the wall will help it will breathe better, but it also reduces compression ratio. Can anybody with experience in this area offer some advice?

Also, What kind of burrs and other abrasives do you recommend? I'm fairly pleased with the above - mentioned burr, but was wondering if others had other suggestions and sources.

Thanks!