Looking for some assistance regarding the lower clutch rod release lever and spring.

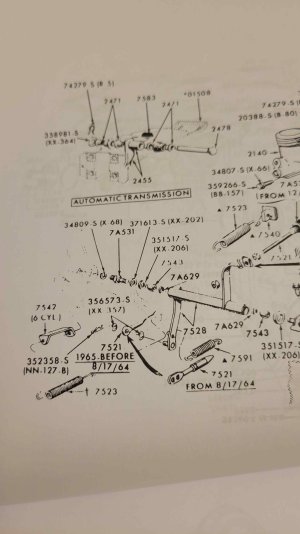

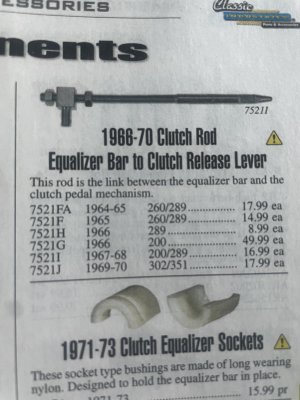

I have a 1964.5 Mustang with a 200ci engine, 3-speed manual transmission. The original engine was swapped out prior to me owning it with a 1968 200ci from a Falcon (if I'm reading my codes correctly). In either case, I don't have the lower clutch rod release lever and spring and would like to purchase a new one. I may have found the correct release lever, but I'm not 100% sure as both the ones I've found on NPD or CJ Pony show it's for the V8 and they don't mention anything about the I6. Furthermore, I'm confused about the spring as the Ford manual exploded view of the clutch shows that prior to 8/17/64 one end of the spring attaches to the clutch fork, but I can't tell where the other end of the spring connects.

The clutch is 9" with the flat flywheel. As they say, a picture is worth a 1,000 words, so I've included some photos to highlight what I'm referring to. My Z bar has one post for the clutch release lever, but that's all - no holes for the spring. The distance from the Z-bar post to the clutch fork is about 6" when the clutch is in the neutral position and approximately 5" if the clutch were engaged.

Any help clarifying the correct parts and spring mounting locations would be extremely appreciated. Photos would be great if you have those to.

Thanks in advance!

I have a 1964.5 Mustang with a 200ci engine, 3-speed manual transmission. The original engine was swapped out prior to me owning it with a 1968 200ci from a Falcon (if I'm reading my codes correctly). In either case, I don't have the lower clutch rod release lever and spring and would like to purchase a new one. I may have found the correct release lever, but I'm not 100% sure as both the ones I've found on NPD or CJ Pony show it's for the V8 and they don't mention anything about the I6. Furthermore, I'm confused about the spring as the Ford manual exploded view of the clutch shows that prior to 8/17/64 one end of the spring attaches to the clutch fork, but I can't tell where the other end of the spring connects.

The clutch is 9" with the flat flywheel. As they say, a picture is worth a 1,000 words, so I've included some photos to highlight what I'm referring to. My Z bar has one post for the clutch release lever, but that's all - no holes for the spring. The distance from the Z-bar post to the clutch fork is about 6" when the clutch is in the neutral position and approximately 5" if the clutch were engaged.

Any help clarifying the correct parts and spring mounting locations would be extremely appreciated. Photos would be great if you have those to.

Thanks in advance!

..

..