Hey, thank you for the tips.

Unfortunately I can't get my hands on a later head, haven't found one in the past 18 months I was looking for it.

I decided to try my best on the small log head, I already did a kind of 2V conversion for my weber 32/36 and I found that someone before me already put hardened seats for both exhaust and intake in it. So I keep the stock valve sizes and the original camshaft, but I am in contact with rocker arms unlimited to get the 1.65 roller rockers. I have a pacemaker long tube header to a single 2.5" outlet with a flowmaster 50series muffler.

For the carburetor I fabricated an adapter plate that will be welded onto the stock air filter housing with a snorkel I got from a 351 air filter. I will route that to the right wheel well as cold air intake. For the ignition I tried to get a DUI unit but had to wait almost a year, so I got a progression ignition instead (so I can play with the advance a little easier). Hopefully all that will wake up the engine a little more...

I already purchased the yellaterra roller rockers with pushrod/lifter kit (when the plan was to change the cam) that I have no use for now. If anyone is interested I will give them away for really cheap. I also have an ACP maxcore 3 row radiator brand new that I don't need because I installed a champion one to clear the stock waterpump fan, if anyone has use for it.

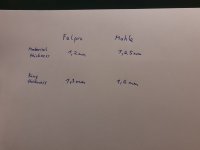

Regarding the gasket: Unfortunately I didn't have the steel shim gasket on the block, there was a felpro on it. I cc'd the combustion chamber and measured 55cc, so the head hadn't been milled when rebuild. That must be why I have so low compression and I hope to change that with the mahle gasket and shaving a few hundrets off the head to get hopefully near the 9.5:1 compression ratio (with stock 7cc measured dished pistons).

So thank you for your help, as soon as I get the gasket I will post some numbers and pictures!