You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

maximum rpms for a 200ci

- Thread starter Patrick66

- Start date

Correct me if I'm wrong, but I seriously doubt it. Maybe a little over 5 g's on a stock bottom end. 6 and change on a built bottom half. That being said, I'm sure someone here has done it or knows how to. I spin mine to about 5 once and in a while(more like every time I drive it), but usually redline it at about 4800 or so. Anything more than that isn't developing any more power and would probably tear up the engine.

I'm running a stock block except for the Clay Smith 264/274 cam and run it to 6,000 rpm and a little bit more quite offten  But remember with the supercharger and lower rear gears (3:80:1) I don't spend a lot of time above 5,000 rpm

But remember with the supercharger and lower rear gears (3:80:1) I don't spend a lot of time above 5,000 rpm

mine had seen about 6k a few times normally revved high 5's also with a stock bottom end

Nor I, and if we did, think I'd be inclined to paper over it...Bort62":1wtr9qwp said:I don't know if I have ever read about someone's bottom end letting go on this forum...

8)

I have heard old school Drag racers used to rev 200 I6 blocks to past 7000rpm's.

But they sure were not stock.

If you run forged rods, CI's billet harmonic balanceer, custom balanced, ARP main bolts, ARP rod bolts, forged pistons, and a head built for high rpm's then yes it can be done.

Even with that setup I would not run past 6500rpm's fro too long.

I have heard old school Drag racers used to rev 200 I6 blocks to past 7000rpm's.

But they sure were not stock.

If you run forged rods, CI's billet harmonic balanceer, custom balanced, ARP main bolts, ARP rod bolts, forged pistons, and a head built for high rpm's then yes it can be done.

Even with that setup I would not run past 6500rpm's fro too long.

Balanced, with a good harmonic damper, and with good rod bolts, the bottom end will sustain 7000. But you'll never get there.

The stock cam gives up at 4400. All done and out of breath.

The stock exhaust gives up at roughly that same level. No more capacity to move more gases.

The log head dies off at about 4800. restricted ports, little valves. No more capacity to breath.

The stock 1bbl carb can only flow enough air for about 4400. All done.

You want to go 7 grand? You have to do something to address all the above, starting with getting one of the new heads and a pretty stout cam to go with it.

The stock cam gives up at 4400. All done and out of breath.

The stock exhaust gives up at roughly that same level. No more capacity to move more gases.

The log head dies off at about 4800. restricted ports, little valves. No more capacity to breath.

The stock 1bbl carb can only flow enough air for about 4400. All done.

You want to go 7 grand? You have to do something to address all the above, starting with getting one of the new heads and a pretty stout cam to go with it.

Patrick66":2e7eou7r said:ive heard that a stock 200 will rev to 7k, is it true. what should i expect from my 200 once i get a late model head, port divider and headers, 3x1 or 2 barrel carb with a stock bottom end.

You should have no problem revving to :

PARTS ON THE ROAD MINUS @ 100 RPM....

The original 170 in the '63 would run out of steam at @ 3500RPM and slowly wind towards 4K with not much more than additional noise.

The Hi-compression @ 9.5:1 - Pursuit 170 engine with worked head ( big valves, veeate springs, divider, milled etc.), 2Bbl and long tube headers but stock bottom & cam revs quickly up to @4K- but wheezes out of power at @ 4500. Built for reasonable MPG as a driver - with some cayunes...

The 250 with 10:1, 3X1 carbs, long tube headers and 272 cam, balanced bottom, custom dampener, ARP fasteners etc. and electronic ignition winds quickly past 5500 still adding power. I've touched 6K with the tach blurry but I get afraid of the $$ winding up on the road after that.

My machinist calls it:

Horsepower per cubic dollar displacement...

Powerband 8)

Patrick66

Famous Member

MustangSix":ux8rfiui said:Balanced, with a good harmonic damper, and with good rod bolts, the bottom end will sustain 7000. But you'll never get there.

The stock cam gives up at 4400. All done and out of breath.

The stock exhaust gives up at roughly that same level. No more capacity to move more gases.

The log head dies off at about 4800. restricted ports, little valves. No more capacity to breath.

The stock 1bbl carb can only flow enough air for about 4400. All done.

You want to go 7 grand? You have to do something to address all the above, starting with getting one of the new heads and a pretty stout cam to go with it.

getting a better cam or maybe just 1.6:1 rockers

dual out headers with port divider and dual exhaust system

getting a later head with the larger valves, mild porting

getting 3 weber 34, or a holley 2 barrel

dont necessarily want to hit 7k, at least not often. probly wont want to hit 6k too often either, its good to know what this motor can take though. so how does a 250 rev with the longer stroke?

Patrick66

Famous Member

also if anybody has experience and knows where my torque and horsepower peaks should be around, let me know.

ill have a stock bottom end, DS 2 (probly with this mod http://fordsix.com/forum/viewtopic.php?t=30894), either a3x1 or a 2barrel, dual out headers, late model head, better valve springs, stock cam (for now) and somewhere around 9.0:1 compression, mild porting. msd blaster 2 coil,

ill have a stock bottom end, DS 2 (probly with this mod http://fordsix.com/forum/viewtopic.php?t=30894), either a3x1 or a 2barrel, dual out headers, late model head, better valve springs, stock cam (for now) and somewhere around 9.0:1 compression, mild porting. msd blaster 2 coil,

Inline6Merc

Well-known member

I ran some virtual dyno runs and this is what i came up with:

1. 2barrel 500cfm, dual out headers, late model head, better valve springs, stock cam (for now) and somewhere around 9.0:1 compression, mild porting. DS II, msd blaster 2 coil,

172hp @ 4500rpms

209ft·lbf @ 3500 rpms

if you add a Classic Inlines cam like say 264 grind you get:

191hp @ 5000rpms

224 @ 3500 rpms

Hope that helps.

curtis

1. 2barrel 500cfm, dual out headers, late model head, better valve springs, stock cam (for now) and somewhere around 9.0:1 compression, mild porting. DS II, msd blaster 2 coil,

172hp @ 4500rpms

209ft·lbf @ 3500 rpms

if you add a Classic Inlines cam like say 264 grind you get:

191hp @ 5000rpms

224 @ 3500 rpms

Hope that helps.

curtis

Inline6Merc":enf8aya0 said:I ran some virtual dyno runs and this is what i came up with:

1. 2barrel 500cfm, dual out headers, late model head, better valve springs, stock cam (for now) and somewhere around 9.0:1 compression, mild porting. DS II, msd blaster 2 coil,

172hp @ 4500rpms

209ft·lbf @ 3500 rpms

if you add a Classic Inlines cam like say 264 grind you get:

191hp @ 5000rpms

224 @ 3500 rpms

Hope that helps.

curtis

What displacement were you figuring ? ... 200 or 250

Patrick66":3s9xrtxb said:ive heard that a stock 200 will rev to 7k, is it true. what should i expect from my 200 once i get a late model head, port divider and headers, 3x1 or 2 barrel carb with a stock bottom end.

As Jack and most everyone else says, the exhast, head and cam usually limit rev range anyway!

To get 7000 rpm, you need

1) a special 310 degree cam with in excess of 450 thou lift at the valve,

2)later large 1.65 to 1.75" stainless intake and 1.45 or greater stainless exhast valves,

3)lots of work to get better exhast flow via headers and head work

4)and a triple intake adaptor with the three biggest carbs you can find.

5)The best cast alloy pistons with clearances up 1.5 thou on what Ford suggests.

That takes you to what Aussies used to race in the 60's with there Falcon engines in speedway, and they got good results.

Back ground info:-

No1: According to early 'hop upsters' who used the Falcon six in power boats and hydosurf racers, a fully blueprinted four main bearing 144 with triple carbs and cast alloy pistons will rev to 8400 rpm, which is a piston speed of only 3500 feet per minute. For a 200, the maximum speed at 3500 feet per second is 6700 rpm. That's the effective limit for a flash run. The 250 can only rev to 5400 rpm with stock pistons. That's the limit unless you get better pistons with better cast alloy and dilled oil relief, rather than the barely stock slotted items we see as replacements in catalogues these days

No 2: Ford rod bolts are plasticine, and will yield and fail under repeated loads.

No 3:Fords cast iron rods, made from about 1968 to about 1974, were not the best. Earlier or later forged rods were better

No 4:The pistons tend to break skirts unless the clearances are very strictly controlled. An engine which is old or has been in service, or rebuilt engine may have issues with the stock replacement pistons...we have about four reported piston gudgeon pin freeze or piston skirt related failures for about 25 recorded 200 cube engine rebuilds since 2002. These were engines under extreame load at the drags at some stages, but essentially street engines modified for performance with good rebored blocks and new HSC Tempo or other good +30 or +40 thou replacement pistons. None were taken to 7000 rpm.

No 5: A really hard worked I6 with hydraulic lifters can simply empty a stock sump at even 5000 rpm, and run main bearings through crank windage, yet there can be a full supply of oil to the head and rocker gear. A stock sump overfilled is insurance, but there are windage trays and high energy style sumps which ensure that the engine won't starve past 5000 rpm.

xecute":2wsovlra said:Patrick66":2wsovlra said:ive heard that a stock 200 will rev to 7k, is it true. .. end.

As Jack and most everyone else says, the exhast, head and cam usually limit rev range anyway!

To get 7000 rpm, you need

1) a special 310 degree cam with ...

--------------------------------------

...sumps which ensure that the engine won't starve past 5000 rpm.

Thanks, That was a great tutorial on the efects of physical forces and practical considerations. Xecute illustrated the details that become the devils when the edge of performance is approached.

Revving my 250 past 5000 - Line-bored mains, precision dampener, balanced shot peened rods, racing pistons, ARP fasteners and Hi-Flo oil pump help the confidence that it will be REPEATABLE...

Powerband

Patrick66":1qibq14r said:or maybe just 1.6:1 rockers

dual out headers with port divider and dual exhaust system

getting a later head with the larger valves, mild porting

getting 3 weber 34, or a holley 2 barrel

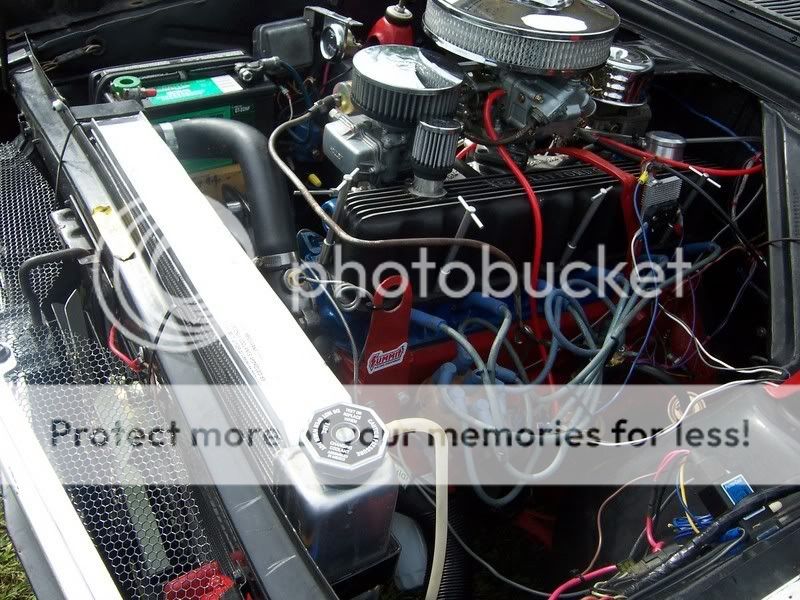

This is basically my engine: ported big log, big valve head with divider and direct mount weber 38 (390cfm), header, & 1.65 roller rockers & DUI on a stock bottom end. It pulls hard from 3000 to 4600rpm. It will rev to about 5000, but nothing really happens above 4600 but lots of noise. It would probably actually be quite quick with a t-5, but I have a c-4.

For the record, this head cost almost as much to build as the new wluminum one.

rocklord":95csxjqr said:MustangSix

What will the Locost rev to? Or have you or your son been brave enough to find out?

I'm not sure. I always close my eyes when the tach gets to about 6k......

Similar threads

All Small Six

1962 Falcon - Swapping a 170 for a 200 plus C4

- Replies

- 5

- Views

- 565

- Replies

- 10

- Views

- 2K

- Replies

- 10

- Views

- 990

All Small Six

Weber 38/38 DGES jets, emulsion tubes and settings

- Replies

- 9

- Views

- 1K

- Replies

- 12

- Views

- 3K