Firepower:

I don’t think I’m following you on the intake over exhaust fix. Can you explain?

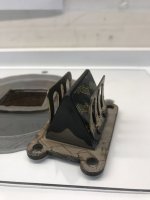

Your reed cage looks massive for the carburetor and engine size. Do I see a volume stuffer?

As far as my challenges, it’s starts with a size constraint. The size constraint makes total flow a challenge, forcing an exploration of lower tension reeds. This lower tension will only be able to perform well under the lower rpm range due to the lower frequency response, throwing the 360 degree intake timing option out the window.

For those that don’t know… the lighter the spring, the less force it takes to move but also the slower the oscillation. This holds true for all springs.

I have purchased .25mm carbon fiber to test against the .40mm resin reeds on the KX 85-100cc reed cage. I hope to have a little more to show next week.

I don’t think I’m following you on the intake over exhaust fix. Can you explain?

Your reed cage looks massive for the carburetor and engine size. Do I see a volume stuffer?

As far as my challenges, it’s starts with a size constraint. The size constraint makes total flow a challenge, forcing an exploration of lower tension reeds. This lower tension will only be able to perform well under the lower rpm range due to the lower frequency response, throwing the 360 degree intake timing option out the window.

For those that don’t know… the lighter the spring, the less force it takes to move but also the slower the oscillation. This holds true for all springs.

I have purchased .25mm carbon fiber to test against the .40mm resin reeds on the KX 85-100cc reed cage. I hope to have a little more to show next week.

Last edited: