oops My Bad ,  It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought it

It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought it

It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought it

It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought it It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought it

It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought itFalconSedanDelivery":2bucteiu said:oops My Bad ,It IS someone on here that has it, I will check my records , Sorry, Ok Update its Gene 64 2dr, that bought it

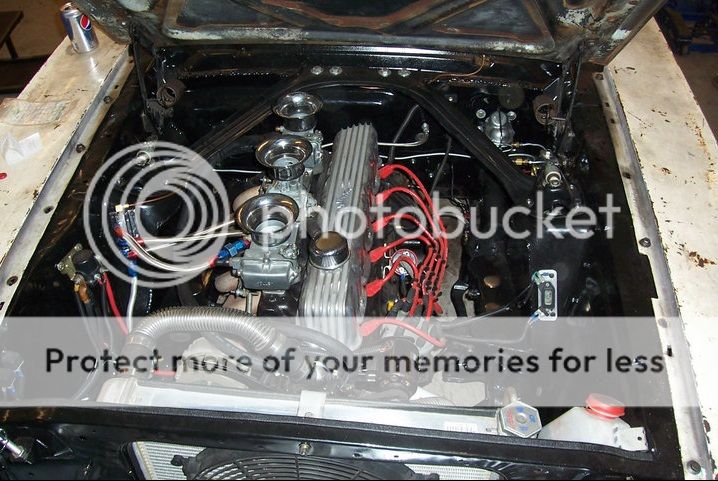

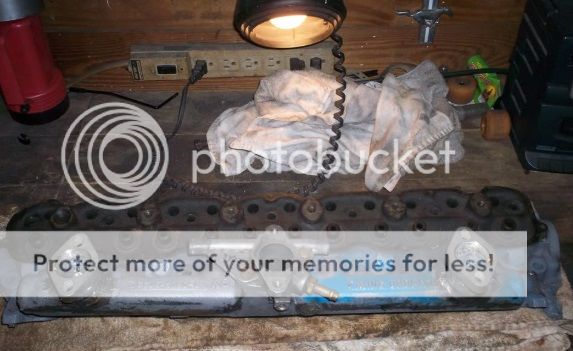

airborne":2bucteiu said:Here are pictures of my 66 Mustang with my homemade tri-power that I built with the help of the combined experience of this site.

http://www.flickr.com/photos/93589044@N ... hotostream

http://www.flickr.com/photos/93589044@N ... hotostream

http://www.flickr.com/photos/93589044@N ... hotostream

You are correct when the only heads available were the factory heads. For the street the oval ports worked great for a street engine.First Fox":1tk2snom said:wsa111":1tk2snom said:...

Prime example, the big block chevy performs better with the oval port heads rather than the rectangular port heads.

With your turbo deal any combination will be better than the naturally aspired intake.

Whatever it will be better than the stock log head. Bill

You are discussing something there that I am very familiar with and with which I have a lot of experience as well. Your comparison is apples and oranges as you are talking about the cross sectional shape and size of a port, not a plenum where velocities are relatively low. And even with that being true, it is not the port SHAPE difference between the two that makes a difference in power or more accurately airflow, it is the overall AREA of the ports. The rectangular BBC ports are much larger than the oval ports and that's where the added airflow and loss of port velocity comes from, not the shape difference between the two styles. There is also a ROUND port variant of BBC heads as well known as "peanut" ports heads, and they have even greater port velocity as the ports are VERY small. And while they make terrific low speed torque, they won't flow enough air to rev past 4000 rpm. Also, the oval port heads indeed do NOT always out perform the rectangular port heads. They are intended for medium speed engines and they excel in those application. The large rectangular port heads excel when reving to 8 or 10 thousand rpm and the peanut port heads are the way to make diesel like torque in a tow rig. Its all about application, same as with a lot of things we discuss.

"sometimes life intersects on a good plan".

First Fox":3i3xopew said:Thank you guys for your response and interest in this project. I apologize for not updating but I was injured in my garage while doing some suspension work and have been unable to do anything with it or barely even type a response here. But I will finish this project and update for you guys because if there is one thing that there is already too much of in these forums is projects that are forgotten or people promising to update and then disappearing for eternity.

I will do this.

First Fox":2ydirv4r said:Thank you guys for your response and interest in this project. I apologize for not updating but I was injured in my garage while doing some suspension work and have been unable to do anything with it or barely even type a response here. But I will finish this project and update for you guys because if there is one thing that there is already too much of in these forums is projects that are forgotten or people promising to update and then disappearing for eternity.

I will do this.

First Fox":18nu8fs5 said:Just touching base again guys. I haven't forgotten about this project and I won't leave tou guys hanging. I am doing side work to pay my bills and am keeping my head above water but I will get back to it when I am on top of things again.

....

Gene 64 2dr":18nu8fs5 said:I'm happy to report that yes, I have FSD 250.

It was a very long trip back late in 2013 to go and get it but well worth the trip. I can't wait to get it installed in my Falcon and get to the strip.

The problem is I still have yet to switch out my 200 with it. I had a very busy 2014 and haven't had any time to get to it.

Growing pains (all good) with a company I started, learning to fly and my son needing a lot of help putting together a 67 Galaxie. FSD also helped him with his knowledge and putting together a distributor for his built up 390.

I have a lot of work to do with the Falcon starting with replacing the rear frame rails then getting the 250 installed.

Unfortunately we will have to wait until at least late April before New England Dragway opens. 14's would sure be nice.

Gene

xctasy":18nu8fs5 said:FWIW, the log mount tri power is a very poor kit, with poor porting giving inconsistant power due to different hole sizes between the center carb and the outers. For the early ones, 1.3 center, 1.09 outer, for the later ones, 1.6875" center, 1.4375" outers. Either way, the air fuel ratios are not even through the rev range, and you have to spend an amount of dyno time to get them working well.

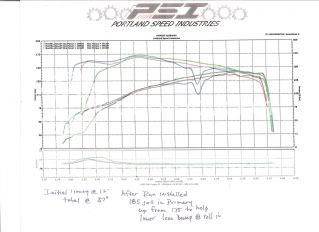

If done right, you can get 143 rwhp with just three 29 mm progressive ICT Weber 1-bbls on a 200 cube 61 Falcon tudor, or over 210 hp with three ' straight unison linkage' Autolite 1101 in the center and 1904 Holley's outboard on a 65 Mustang (Drag car only) 250 Six + goodies , , 14.39 so far.

For 200 dyno figures, see kevinl1058 on http://fordsix.com/forum/viewtopic.php?t=64712.

Flywheel Corrected # 177.05H.P., 204.20 lb-ft

H.P. peak at 5100 RPM. Torque Peak at 3250 RPM

Video http://vimeo.com/20044528

For 250 quarter mile figures, see FalconSedanDelivery.

#108 by FalconSedanDelivery » Tue May 10, 2011

http://fordsix.com/forum/viewtopic.php? ... 31#p502631

This guy is too quiet, his set up is very creditable 200-225 flywheel hp, and most likely the most powerful triple 1-bbl around. He runs a unison linkage, high initial advance of 16 to 18 degrees, total timing to 30 degrees its all in at 2350, decked block 100 thou and head 120 thou for huge 12.3:1 C/R, and the worlds neatest tri power intake ever seen. His 14.39 @ 90.76 mph was is shifted at 5000 and 4300 at the traps, earlier runs were 5200 and 4700 rpm. He ran with 3.5:1 gears for the 14.39. Best 60 foot time 1.915 secs in a 2600+ pound car with a an estimated 165 at the rear wheels.