Hi guys, could use some advice.

1966 Mustang

C4 tranny (unknown year, suspect late 70's)

brand new rebuilt 200

I just rebuilt a spare engine from craigslist. 1965 block. Reused the flexplate that was on the engine and the spacer ring, plus the upper and lower dust shields. Visually everything looked the same.

I removed the old engine and put the "new "one in. Left the C4 tranny in the car during the process. When I put the engine in, I had a bit of trouble with the alignment, it took several tries with the hoist. Might have banged into the torque converter slightly... pushing it back? I was sure to check that it smoothly rotated by hand before continuing. Finally got the dowel pins aligned and torqued up the bolts. everything seemed to line up well...

When I looked at the flexplate to torque converter, i was surprised to see a small gap between the two. The studs welded to the torque converter were engaged in the flexplate holes. I wish I could have gotten a feeler gauge or something in there to measure, would estimate it at about 0.150" - 0.200"? Is this normal? I put the nuts on the studs and slowly tightened them down as I rotated the engine to the 30 ft-lbs in the manual. There appeared to be clearance with the upper dust shield... I couldn't tell what was moving - was the flex plate flexing, or was the torque converter moving forward?

Did some research and found some sites that seemed to indicate this is typical... scoured the shop manual and couldn't find anything. I pressed on.

http://garage.grumpysperformance.com/index.php?threads/installing-a-torque-converter.2400/

http://www.rosslertrans.com/tech.html

Engine break in went ok... no unusual noise and after draining oil it looked great. No fluid leaks. Only problem is I failed to add some Type 4 fluid to make up for what I lost when the radiator was out. I couldn't check at the 2500rpm break in speed. After changing oil and refilling I started up and checked again. Added a quart or so. Now checks good.

Backed it out of the driveway under power and stepped on the gas... got a horrible chattering noise. Sounds rhytmic and like something rotating is hitting. I backed off the pedal and it went away. Pressed slowly and it was ok at first but then came on after lightly touching the gas. Weird thing is, it's only while in drive under load. If it's in idle, there's no noise. I can rev it fairly high (4000 rpm - all I'm willing to go on a new engine) and there's no noise. But the moment I step on the gas in gear, it rattles... LOUD... not just a tap... seems to be coming from the rear of the engine, but only in drive. Limped it home and looked things over. No fluid leaks (red or otherwise) and I don't see any damage.

I've read a lot about cracked flexplates and bolts hitting the dust cover, etc... it does sound like that but I don't see evidence of that going on.

Questions:

*are there different flexplates for inline 6's? I used the one that came with the engine. It visually looked the same as the one that was on the "old" engine, but didn't take measurements.

*was this gap between the flexplate and torque converter normal?

*could I have shoved the torque converter back into the tranny during engine install and done damage?

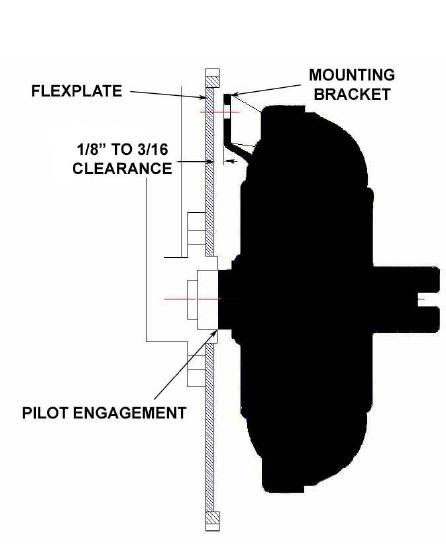

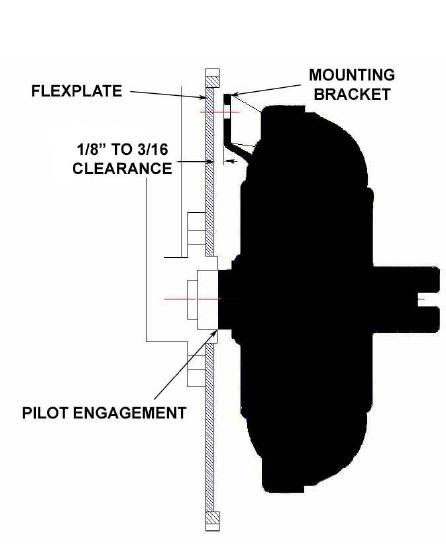

*Is it possible the nose of the torque converter somehow isn't aligned with the crank or flexplate ("pilot engagement") like the photo above)?

*could engine break in while down a quart on fluid done damage?

*why is the noise only there in drive and not in neutral?

Any help or thoughts on how to proceed much appriciated.

I'm thinking I should:

Loosen the torque converter nuts, remeasure my gap.

Leave the engine, loosen the bolts to the tranny and push it back, try to realign?

1966 Mustang

C4 tranny (unknown year, suspect late 70's)

brand new rebuilt 200

I just rebuilt a spare engine from craigslist. 1965 block. Reused the flexplate that was on the engine and the spacer ring, plus the upper and lower dust shields. Visually everything looked the same.

I removed the old engine and put the "new "one in. Left the C4 tranny in the car during the process. When I put the engine in, I had a bit of trouble with the alignment, it took several tries with the hoist. Might have banged into the torque converter slightly... pushing it back? I was sure to check that it smoothly rotated by hand before continuing. Finally got the dowel pins aligned and torqued up the bolts. everything seemed to line up well...

When I looked at the flexplate to torque converter, i was surprised to see a small gap between the two. The studs welded to the torque converter were engaged in the flexplate holes. I wish I could have gotten a feeler gauge or something in there to measure, would estimate it at about 0.150" - 0.200"? Is this normal? I put the nuts on the studs and slowly tightened them down as I rotated the engine to the 30 ft-lbs in the manual. There appeared to be clearance with the upper dust shield... I couldn't tell what was moving - was the flex plate flexing, or was the torque converter moving forward?

Did some research and found some sites that seemed to indicate this is typical... scoured the shop manual and couldn't find anything. I pressed on.

http://garage.grumpysperformance.com/index.php?threads/installing-a-torque-converter.2400/

http://www.rosslertrans.com/tech.html

Engine break in went ok... no unusual noise and after draining oil it looked great. No fluid leaks. Only problem is I failed to add some Type 4 fluid to make up for what I lost when the radiator was out. I couldn't check at the 2500rpm break in speed. After changing oil and refilling I started up and checked again. Added a quart or so. Now checks good.

Backed it out of the driveway under power and stepped on the gas... got a horrible chattering noise. Sounds rhytmic and like something rotating is hitting. I backed off the pedal and it went away. Pressed slowly and it was ok at first but then came on after lightly touching the gas. Weird thing is, it's only while in drive under load. If it's in idle, there's no noise. I can rev it fairly high (4000 rpm - all I'm willing to go on a new engine) and there's no noise. But the moment I step on the gas in gear, it rattles... LOUD... not just a tap... seems to be coming from the rear of the engine, but only in drive. Limped it home and looked things over. No fluid leaks (red or otherwise) and I don't see any damage.

I've read a lot about cracked flexplates and bolts hitting the dust cover, etc... it does sound like that but I don't see evidence of that going on.

Questions:

*are there different flexplates for inline 6's? I used the one that came with the engine. It visually looked the same as the one that was on the "old" engine, but didn't take measurements.

*was this gap between the flexplate and torque converter normal?

*could I have shoved the torque converter back into the tranny during engine install and done damage?

*Is it possible the nose of the torque converter somehow isn't aligned with the crank or flexplate ("pilot engagement") like the photo above)?

*could engine break in while down a quart on fluid done damage?

*why is the noise only there in drive and not in neutral?

Any help or thoughts on how to proceed much appriciated.

I'm thinking I should:

Loosen the torque converter nuts, remeasure my gap.

Leave the engine, loosen the bolts to the tranny and push it back, try to realign?