Enjoy your 144. I wouldn't spend a dime on a smaller than ideal engine unless I could recoup the 70 gross hp its looses compared to the 250 sixes one time factory rating of 155 hp and it'll always have a poor power to weight ratio.

Its just that good used cams from 200's and 250's are always 256 degrees and 370 or 400 thou lift, and are everywhere for this engine, often in good shape.

With new solids and some cam paste and proper break in procedure, you'll be fine.

Since you can't easily redrill the block for the lifter feed, this is the process.

Swap in a 200 or 250 cam that is servicable. Use new solid lifters and adjust to 6 thou intake, 8 thou exhaust. Pushrods then need to ensure the tips of the rockers wipe over the middle third of the the valve from zero to full lift.

http://www.hotrod.com/articles/how-to-m ... -pushrods/

Process 9 to 12 is the key. Use stock pushrods from your 144 and just check that the middle third of the valve tip is centered. You only need a checking pushrod if its out of alignment.

Normally, you wouldn't

ever mix and match solid and hydraulic cams, as the hydraulic cams are designed for lifter preload, and have a 6 thou ramp, while solids are about 13 thou or so. Since you've got a 144, then you don't have any other cost effective options , asside from calling Schnider,Howards, or CalySmith, and going to a full cam upgarde. They'd sure laugh if, when asking what upgrades the engine has, and you say "none".

Change the valve springs,valve seals, and use lapping compound to reseat the valves if your taking the head off. You can use the common 200 gasket, have the head planed, and enlarge the log heads hole to 1.75" or even larger, and do all the hand blue printing , 3 angle back cut and valve alterations that the two True Brothers of Speed espouse in this book.

For my experience, I had an old 138cubic inch GM in line six, same kinda deal as yours, but only 77.9 hp, 6.8:1 compression, in a 2550 pound car with no real guts. But after a better wider ratio four speed gearbox, a 3.45:1 axle ratio, and a pressure regulator to stop my 1-bbl Zenith 34 VNT leaking, I got a lovely little cruiser that sounded gorgeous, and was reliable and loved by everyone on the road. Old cars make freinds.

Note: Its okay to be cheap, just don't wreck it...

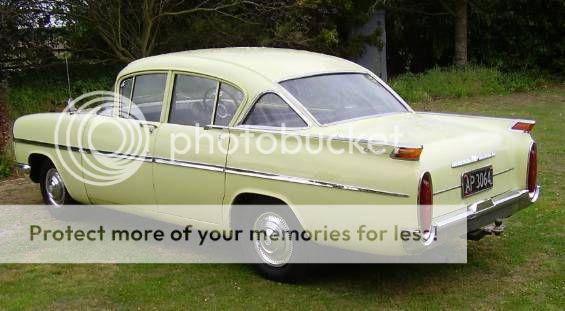

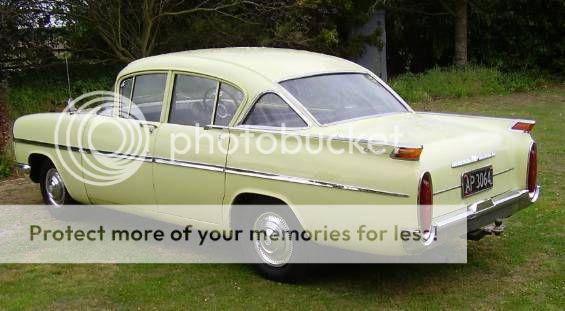

As a kid, I was always a Vauxhall Velox and Cresta man myself, more cubes, 8.8" diff, 12 port head and bomb proof, laycock overdrive optional, you could wack a 4 speed with over drive and get seven speeds into it.

Often you'd just find the parts at a municpal tip like I did

the first car to win the Armstrong 500 mile endurance races

http://holden.itgo.com/bathurstwinners.html

and they were just a sh!+ load stronger than the old Ford Falcons and British Zephyr Zodiacs, but I studied every inch of every British Ford and GM in line six cylinder part while raiding the local deserted landfill...

When 17 in 1987, I did my first diff swap on my PA, 3.9:1 3 speed to 3.45 4 -speed, and then did my first engine swap and engine build.