aPanzerIV":125w19df said:

Hello all,

I've got a '81 Fairmont wagon with a 200, C4, and 2.73's. Most of my driving is 50-60mph backroads so I'd like to keep the 2.73's for now.

I've noticed the car tends to fall flat on it's face after 3500rpm's. I looked up the cam specs and the stock cam is tiny, no wonder!

I want something with good low-end torque and economy with a small bump in power and rpm's.

Right now I'm looking at Comp Cam's 252H or a Howards 280108-12.

In the future I'm planning on having a DUI distributor, 6-1 headers, and a 2 barrel conversion with a 2100/2150, so something flexible would be best.

Thank you for your time!

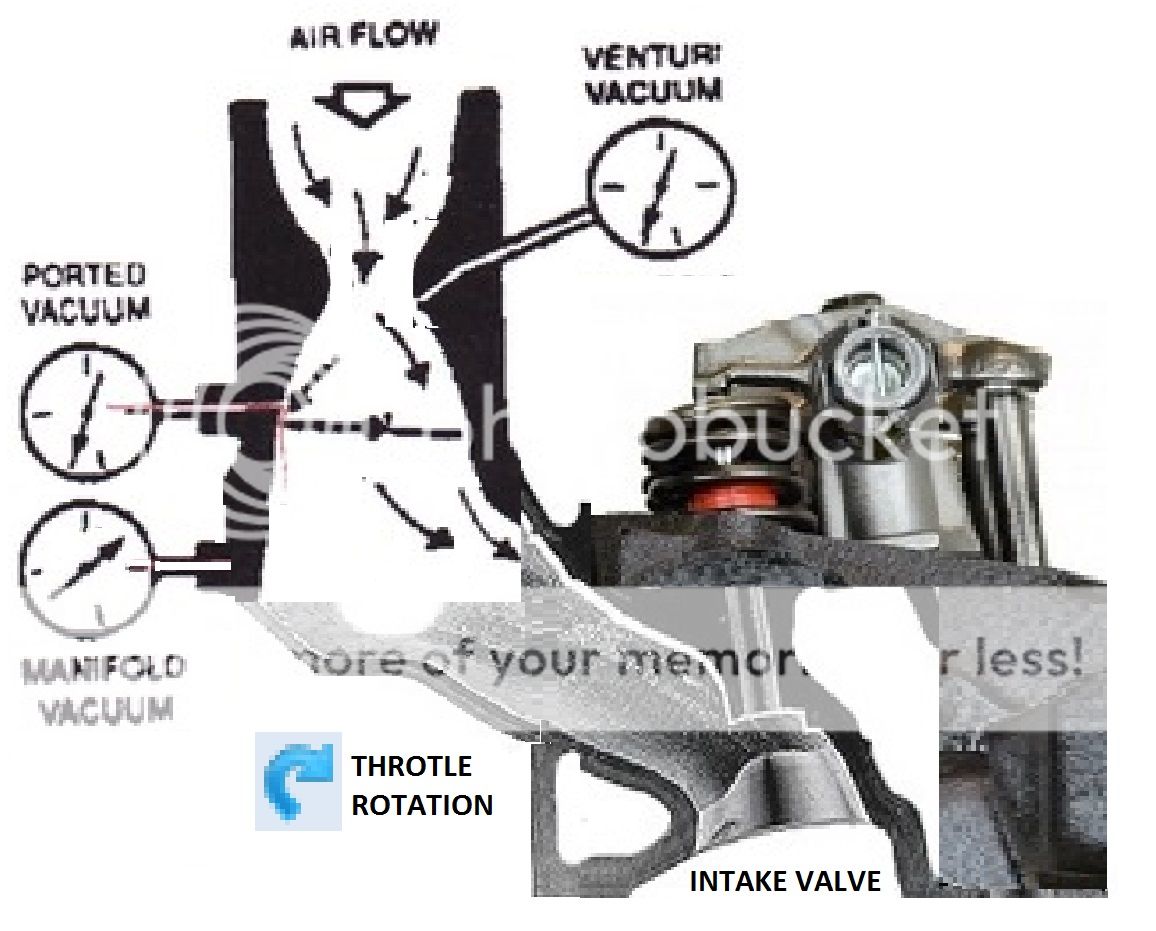

Its not cam timing, its lift, peak air flow, and the lack of adequate time for the 1-bbl carb to feed the six loaded bases of the stock 3.3 from 3500 to about 5300 rpm, where it actually tops out.

You need a little more compression, more carburation, more valve lift, and more intake flow. You could get by with the stock intake flow if you ran triple carbs. You could effectively gain what would feel like 1.3 liters or 68 cubic inches by adding a floor change manual gearbox.

Everthing listed below.....

The issue with all 3.3's in a 3400 pound wagon is that its carrying a lot of weight, an auto that is just like loosing 21 hp off the 1981 factory rating of 91 hp.

An auto is like taking and 3.3/200 engine, and winding off 1.3 liters, making it like a 2.0 72 hp Ranger engine.

The 1979 and later 1983 2.8 2-BBL V6 made 18 to 23 hp more than the 3.3 (109 and then 114 hp), easily enough to bring back the power balance in favour of a proper 3.3.

In Australia that, year, a 3.3 liter engine made 114 hp, the cam was the same duration as the US 3.3, the carb a 1-bbl and it had a more restrictive exhaust.

The Aussie 3.3 made more power by extra cam lift via 1.73:1 rockers and 145 cfm of intake flow at 435 thou vlave lift in the head, and a detonation reistant 9.15:1 compression head on 97 octane gas.

The V6 made the extra power via 276 degree cam duration and a V8 spec 1.14 " 2-BBL carburator. Its heads flowed 110 cfm at 400 thou lift. It did that with less than a 8.7:1 compression ratio, 87 octane gas.

Emission control only required a lower compression ratio to meet the 50000 mile durablity test, and avoid breaking the cast iron con rods.

So how do you close the difference between the 109 and 114 hp engines verses the US 3.3, and make more torque?

1. Move to a T5 manual or SROD 4 speed gearbox with a 0.81:1 top gear and your exiting 2.73 axle.

That gives you an extra 18-23 more flywheel horspower, and the dyno reading goes up from the 56 RWHP most C4 autos made, to the 72 hp the 1981 Manual cars made.

Stormin'Normans car is an example.

viewtopic.php?f=1&t=72938&p=592202#p592202

viewtopic.php?f=1&t=71746&p=585486#p585486

2. Do the Falcon Six Performance Handbook modifications to improve peak and avergae head flow CFM. Its about 125 cfm at 400 thou at the moment on a 28"Hg pressure drop. The FSPHB mods of vlave back cutting and 3 angle vlave grinding and finding some aftermarket 1.6:1 rockers will raise that to 145 cfm at just 400 thou pretty smartly.

3. Cam just needs more lift, not a lot more duration, especially if your cars gonna remain automatic. About 264 at lash for a hydraulic cam is about all you want to add.

JackFish's Station Wagon is an example of how great a 264 Degree Clay Smith cam can be on a 1-bbl 3.3 Fox engine.

viewtopic.php?t=65908

The 252 and Howards cams are 264 Clay Smith work-a-likes.

4. Compression can be booted almost half a point from the 8.4:1 stock ratio,

up to 8.7:1 with 87 Octane

or 9.1:1 with 91,

or 9.3:1 with 93,

or 9.8:1 with 98.

If you manage detonation by a recurved DS11 or TFI ignition with the 1986 Ford Piezo electric knock sensor , and you don't polish the intake runners on incomming bowl, you can go up another 0.3 on the 8.7:1 base, which is at each step, another 0.6:1 extra

up to 9.0:1 87 octane

or 9.4:1 with 91,

or 9.6:1 with 93,

or 10.1:1 with 98.

If you add the Clay Smith 264 cam, you can go up a little on that.

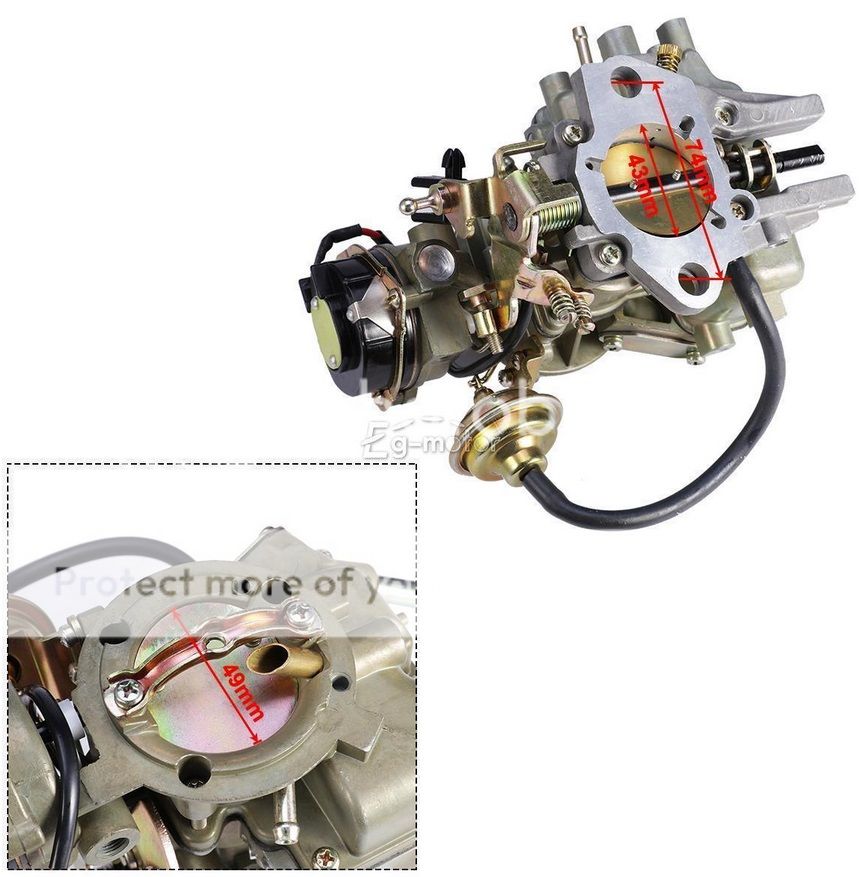

What really makes these engines crack is three or four carbs. Three YFA Carters with the 1983-1987 Mixture Control Solenoid takes three 72 to 88 hp 2.0/2.3 liter Ranger/Mustang 2.3/Fox 2.3 carbs, and it can cycle the fuel delivery to meet 12.5:1 under acceleration, and 14.7:1 under cruise (12.5:1 is now 12.8:1, and 14.7:1 is now 15.1:1 with modern US Gasoline).

Oh, sorry, "Mixture Control Solenoid", or MCS. No longer serviced part, sort of like Photobucket refusing to help you post photos...

I was serious about the Carter YFA carb. To add to these complicated 35 year old veteran carbs with check valve and variation prone issues already AND THEN add a very sophisticated EECIV control module was, um, optimistic....

FrenchTownFlyer from Ford Six.Com said it best

"Was there ever a less helpfull feedback carb system....I doubt it!"

As a utility maintenance worker, I did work on Liquid Propane conversions, and the Ak Miller writen TSB manual said this trouble some piece could be jumpered by an Impco Fuel Control Valve, which then allowed the EECIV computer and MCS to behave normally, but it would be remote controlled by another system, Impcos Command Module.

MCS-8 Ford 1 Barrel YFA Pulse Solenoid 1983-86 Ford & Mercury 4 cyl., 1983-84 Ford Truck 4 cyl.

The Fox Holley 1-bbl 1946, and the HSC Tempo/Topaz Holley 1949 6145, 6149, 6153, look the same as the YFA Feed Back Carb, but are not the same, and don't have the Mixture Control Solenoid.

Ford's generic 4 cyl 2.3 OHC replacement part is

E4PZ-9S565-C

Walker 318-2006 still supply it

Its Standard Motor Part MX-33

"http://www.ebay.ca/itm/

Standard-MX33-NEW-Mixture-Control-Solenoid-FORD-MERCURY-1983-1986-/282029461641"

MCS-9 Ford 1 Barrel YFA Pulse Solenoid 1983-86 Ford Truck 6 cyl.

No longer serviced

But its Standard Motor Part MX -32

"http://www.ebay.com/itm/

Mixture-Control-Solenoid-Standard-MX32-fits-1983-Ford-F-150-4-9L-L6-/162474041769?hash=item25d43521a9:g:0hIAAOSwjDZYmbf0&vxp=mtr"

See

https://fordsix.com/viewtopic.php?t=49168

Its basically fine untill the Pulse Width Modulated Mixture Control Solenoid goes on holiday. Then it retards igntion to a set amount, and the EECIV goes into a Skylab orbit, and crashes because the TFi, O2 sensor and MCS cant work within normal limits. The idle surges, and the miles per gallon goes up to 460 Big block level....

EECIV is not a system I'd recommend unless you convert to a TFi ignition.

These things run best at leaner than the 14.7 :1 indicated or 15.1 actual on todays fuel blends. 15.5 or 16.1 is possible.

I am serious about the Carter YFA carb being an option. Technology is so cheap now, and the parts supply for this carb has improved considerably.

The YFA Feedback Two Step metering rod info exists now, too. The Feedback YFA has two kinds of generic calibration, that is changed with just the metering rod and Mixture Control Slenoid.

For Use with two kinds of Mixture Control Solenoid 2.3 Ranger/Mustang/Capri E4PZ-9S565-C or MX 33 or MCS-8

or the much richer Big Six 4.9 MX 32 or MCS-9 and its two step rod.

The controlling system I'd use is the very simple Arduino PWM computer, about 65 buxs, and a cat mounted O2 sensor, and front head stud mounted knock sensor.

E6RF 12A69BA sensor is the orange inserted item in one of XFlow_Fairlane's post #6

GM'S 1986-1996 1997562,10456017,10456287 (Tomco 29014) knock sensor

I like the Ford US stuff, but most Aussie EECV's use a similar Tomco's 29061 1998 Ford

and Mercury 1998-1999 # F8CZ 12A699 AA part with a two pin power up, and a second pin sensor check.

If you use the 1985-1986 Ford Mustang 2.3 EECIV or F150 4.9 1984-1987 EECIV to run it all,

Pin 32 should read 0v ign on & 0.2v with engine running.

Pin 57 should read 0.2v when ign on or engine running

viewtopic.php?f=2&t=76154

You can use EECIV or Arduino PWM computer to program the MCS and Knock sensor. And then run three 100% stock 2.0/2.3 4 cylinder OHC Lima engine carbs for about 168 dollars each. These 160 cfm at 1.5"Hg carbs are just like the 4.9 Feedback F150 and E150 truck carbs, same 1-11/16" throttle, and 1-5/16" venturi as the Fox Holley 1-bbl 1946, and the HSC Tempo/Topaz Holley 1949 6145, 6149, 6153. 43 mm carb, 33 mm throttle venturi.

That allows you to feed all six cylinders evenly, with a synchronised linkage. With a 264 cam, you'll get 188 hp with the stock 4-1/4" foot ball primary light off catalyst.

The same cam, with headers, made

kevinl1058 181 flywheel hp and 144 rwhp with a T5 and three ICH/ICT 34 mm carbs with 29 mm venturis.

viewtopic.php?t=64712

The time honoured Offy Tripower intake makes a

lot of power with small carbs, but with proper fuel managment, it makes a lot more power with big carbs on a modest tune. Engine Analyser Dyno runs are pretty accurate, the Tripower is a very competent piece, a lot better than many realise.

People who think 80's era emissions 3.3 barges are guttless, and they are stock.

Just reading Ak Millers 1967 to 1984 Autolite, Magazine, Jay Storer Propane Perfomance and 1985 Impco Technical Service Memoradums, and are missing the HUGE amount of really simple stuff that it is around. As the man himself said, there's a lot a

good things in fuel managment.

Its a matter of getting fuel to cylinders. Eliminating seven sharp bends, and reducing the duty cylce of a 1-bbl carb with three carbs feeding two cylinders instantly increase HP out of sight. Anything you do with one carb feeding six cylinders isn't going to make a distribution problem any better.

So without a turbo, you can kick your rwhp up from 56 to 114 rwhp with an automatic, and from 72 rwhp to 149 rwhp with a T5 or similar manual gearbox. A 107% increase.