Linc's 200

Well-known member

It is a Fox body, has more room to work with

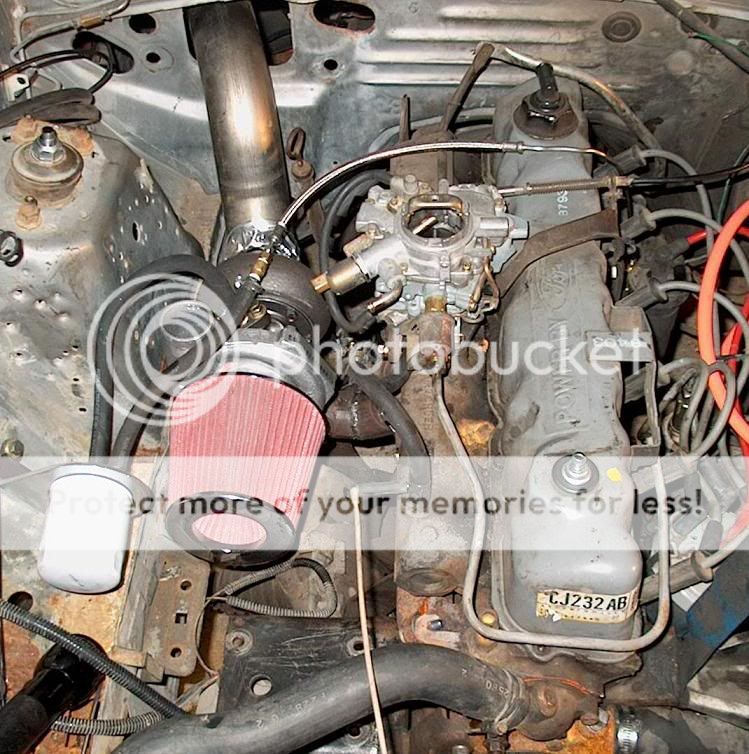

(edited bad photo links)

That last pic was so we could run it and make sure there were no leaks. The downpipe is temporary (of course!!!) and was in place so we could start it at 2 AM and not wake all the neighbors (The interior of a car makes a great muffler!)

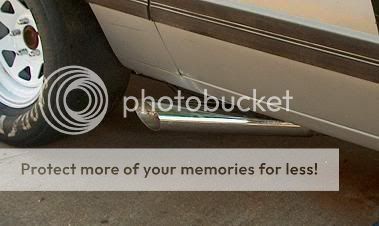

I now have the permanent downpipe in place, and the exhaust all the way to the tip is done. I am also in the middle of finishing the intercooler set-up and will be posting more pics soon.

Peace out,

Linc

(edited bad photo links)

That last pic was so we could run it and make sure there were no leaks. The downpipe is temporary (of course!!!) and was in place so we could start it at 2 AM and not wake all the neighbors (The interior of a car makes a great muffler!)

I now have the permanent downpipe in place, and the exhaust all the way to the tip is done. I am also in the middle of finishing the intercooler set-up and will be posting more pics soon.

Peace out,

Linc