Daves55Courier

Well-known member

Some of you who are familiar with Holley 1904 flooding problems due to mating with 5-7 lb pressure fuel pump now have a permanent fix without the use of a fuel pressure regulator. You may remember in previous posts, I had mentioned using several pressure regulators that only lasted one month each. Here is how I fixed the problem.

Drain gas tank and remove it and allow to air dry out thoroughly over a long period of time. There can be no gas fumes present for the modification to ensue during this operation. Locate a spot near top rear passenger side of tank that will be easily accessible with hands and tools when gas tank is re-installed in the car. Drill a 1/4" diameter hole in the tank at that location. Cut a piece of 1/4" tubing about 1 inch long and weld it to that hole with a mig welder. It will be necessary to arrange a clamp and ground wire to the tubing to make sure the weld will spark to it. Weld all the way around continuously.

As an added precation to make sure it is a leakproof seal, mix up some JB-Weld and smear it all around the weld. Let thouroughly dry.

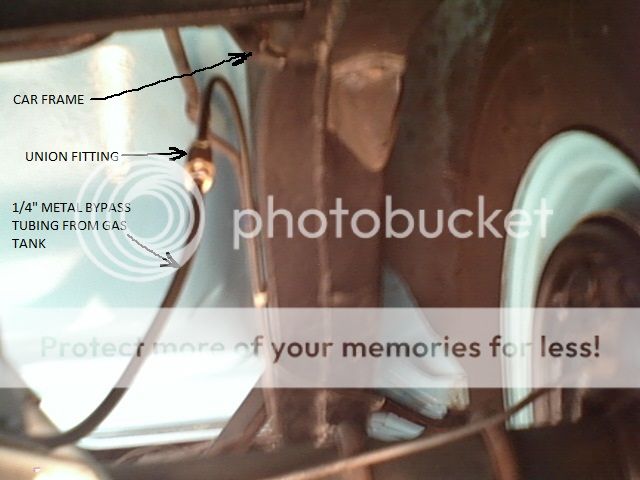

Re-install tank in car and connect fuel line hose and metal tubing along tank flange, car frame and up to the engine on passenger side adjacent to the fuel supply line. This new line will be your fuel bypass.

Intercept your existing fuel supply line as high as possible (at the level of the valve cover preferably) and cut out a prtion of that tubing to receive a Mopar bypass filter mounted horizontally with the bypass port facing upwards.

Continue running your bypass line up and make a U-turn down into the bypass port of the bypass filter which is aiming upwards.

Now disconnect the 5/16 inch supply line at the carburetor and insert a piece of smaller size tubing that will fit inside the supply line. The length of that tubing should be cut such that the inside piece stops at the first bend in the tubing and runs all the way into the fuel inlet fitting in the carb. This piece will serve as an orifice to create back pressure to fill the fuel bypass line. The bypass filter is mounted at about the same level as the carb so that it will not begin to overflow into the bypass port until the float in the carb attempts to stop the flow. This arrangement might now work if the bypass filter were installed down by the fuel pump, because the fuel might begin to fill the bypass line before it even gets to the carb. Also I mentioned placement of the fuel bypass line at top rear of the tank because the fuel level in the tank is lowest at the rear, even when tank is full of gas, the fuel level is still below the bypass entry into the tank. You wouldn't want to place the bypass entry into the bottom or middle of the tank because head pressure in the tank would restrict bypass fuel from entry into the tank.

I have installed this as described above and now the engine idles and runs at any speed without any carb flooding.

Drain gas tank and remove it and allow to air dry out thoroughly over a long period of time. There can be no gas fumes present for the modification to ensue during this operation. Locate a spot near top rear passenger side of tank that will be easily accessible with hands and tools when gas tank is re-installed in the car. Drill a 1/4" diameter hole in the tank at that location. Cut a piece of 1/4" tubing about 1 inch long and weld it to that hole with a mig welder. It will be necessary to arrange a clamp and ground wire to the tubing to make sure the weld will spark to it. Weld all the way around continuously.

As an added precation to make sure it is a leakproof seal, mix up some JB-Weld and smear it all around the weld. Let thouroughly dry.

Re-install tank in car and connect fuel line hose and metal tubing along tank flange, car frame and up to the engine on passenger side adjacent to the fuel supply line. This new line will be your fuel bypass.

Intercept your existing fuel supply line as high as possible (at the level of the valve cover preferably) and cut out a prtion of that tubing to receive a Mopar bypass filter mounted horizontally with the bypass port facing upwards.

Continue running your bypass line up and make a U-turn down into the bypass port of the bypass filter which is aiming upwards.

Now disconnect the 5/16 inch supply line at the carburetor and insert a piece of smaller size tubing that will fit inside the supply line. The length of that tubing should be cut such that the inside piece stops at the first bend in the tubing and runs all the way into the fuel inlet fitting in the carb. This piece will serve as an orifice to create back pressure to fill the fuel bypass line. The bypass filter is mounted at about the same level as the carb so that it will not begin to overflow into the bypass port until the float in the carb attempts to stop the flow. This arrangement might now work if the bypass filter were installed down by the fuel pump, because the fuel might begin to fill the bypass line before it even gets to the carb. Also I mentioned placement of the fuel bypass line at top rear of the tank because the fuel level in the tank is lowest at the rear, even when tank is full of gas, the fuel level is still below the bypass entry into the tank. You wouldn't want to place the bypass entry into the bottom or middle of the tank because head pressure in the tank would restrict bypass fuel from entry into the tank.

I have installed this as described above and now the engine idles and runs at any speed without any carb flooding.