I've been wanting to do a thread on EEC-IV for a while now. It's just old enough and obscure that a thread with all the relevant bits in one place should make for a nice resource. I was a Ford dealer tech starting in '86, sticking with the brand until 1999, so these systems were my bread and butter at the start of my career.

I should mention briefly the predecessors to EEC-IV. It's a good time to insert the link to the Wiki:

https://en.wikipedia.org/wiki/Ford_EEC

EEC-III was the direct predecessor of EEC-IV. It was used in feedback carb and throttle body (CFI in Ford speak) systems. EEC-III used a crank-mounted sensor for RPM. The distributor only distributed spark through a wide body cap with internal routing to provide symmetry of spark plug wire routing. There were no sensors inside the distributor. ECM was under dash. The biggest failing to this system was the unsealed connectors between the crank sensor and ECM, and the harness routing in the vee between the intake and valve cover, an often oil-soaked area (What? Fords leak oil?).

Ford also used MCU (Microprocessor Control Unit) on various vehicles until the mid-late '80's. It was a very simple system, controlling a feedback carb and emissions systems on the vehicle. The only timing control was the ability to retard spark via the Duraspark module. This system hung around and was offered parallel to EEC-IV in police and emergency vehicles. It's advantage was the ability for the vehicle to run with the ECM unplugged, useful in that role. You can tell MCU from EEC-III (besides the goofy EEC-III distributor cap) as the MCU ECM was under the hood.

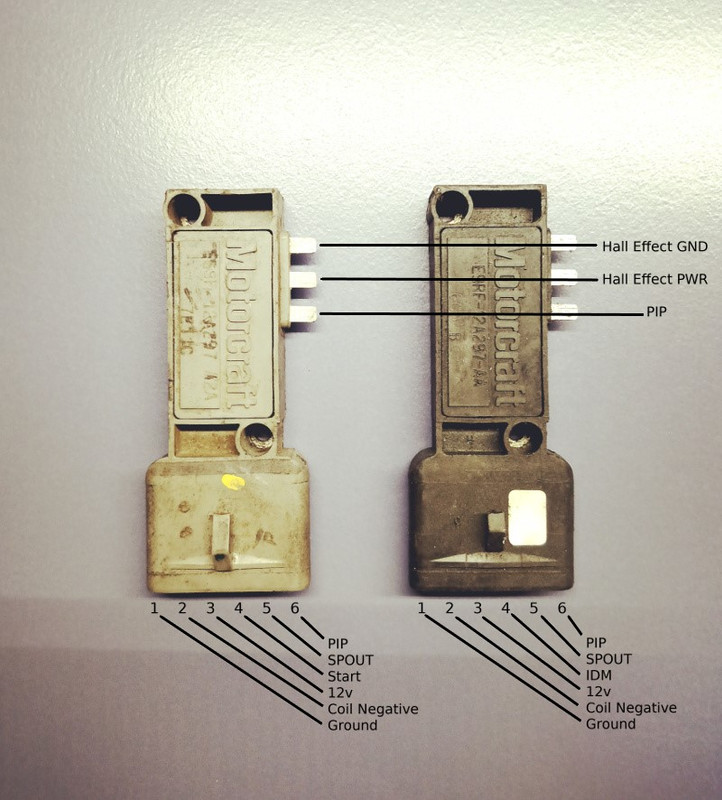

The single easiest indicator you have an EEC-IV system is the presence of a TFI-IV ignition module. Early cars had them mounted to the distributor, later ones moved to a remote heat sink. I won't go into TFI issues with this post, as it's easy enough to substitute a known good module for diagnosis. I carry a spare module and wrench in all my TFI-equipped vehicles.

The earliest EEC-IV systems (early 80's) were feedback carb or CFI. CFI was a short-lived engineering bridge between carbs and port injection. By '86, the 5.0L was port-injected and SEFI (Sequential Electronic Fuel Injection). These cars were a significant step forward in driveability and power/torque production compared to the CFI/carb vehicles they replaced. Trucks used a similar system that was bank-fired instead of SEFI, and used higher fuel pressure. There were only two significant issues with the early port-injected cars/trucks. First was oil consumption. Port injection allows a high flow PCV valve, so Ford went to low tension piston rings with the port-injected engines. It took a few years to get the bore/ring interface correct, and it's not uncommon for the early ones to burn a quart of oil every 1,000 miles. the second was injector clogging. It was found that fuel would hang on the injector tip after shut down and evaporate, leaving deposits on the tip of the injector. Flow would degrade over time requiring injector cleaning or replacement. Ford scrambled to update the design of the injector to move the pintle up into the body of the injector which helped, but in 1988, ethanol was approved as an additive in pump gas. Injector problems went away after that.

<to be continued>

I should mention briefly the predecessors to EEC-IV. It's a good time to insert the link to the Wiki:

https://en.wikipedia.org/wiki/Ford_EEC

EEC-III was the direct predecessor of EEC-IV. It was used in feedback carb and throttle body (CFI in Ford speak) systems. EEC-III used a crank-mounted sensor for RPM. The distributor only distributed spark through a wide body cap with internal routing to provide symmetry of spark plug wire routing. There were no sensors inside the distributor. ECM was under dash. The biggest failing to this system was the unsealed connectors between the crank sensor and ECM, and the harness routing in the vee between the intake and valve cover, an often oil-soaked area (What? Fords leak oil?).

Ford also used MCU (Microprocessor Control Unit) on various vehicles until the mid-late '80's. It was a very simple system, controlling a feedback carb and emissions systems on the vehicle. The only timing control was the ability to retard spark via the Duraspark module. This system hung around and was offered parallel to EEC-IV in police and emergency vehicles. It's advantage was the ability for the vehicle to run with the ECM unplugged, useful in that role. You can tell MCU from EEC-III (besides the goofy EEC-III distributor cap) as the MCU ECM was under the hood.

The single easiest indicator you have an EEC-IV system is the presence of a TFI-IV ignition module. Early cars had them mounted to the distributor, later ones moved to a remote heat sink. I won't go into TFI issues with this post, as it's easy enough to substitute a known good module for diagnosis. I carry a spare module and wrench in all my TFI-equipped vehicles.

The earliest EEC-IV systems (early 80's) were feedback carb or CFI. CFI was a short-lived engineering bridge between carbs and port injection. By '86, the 5.0L was port-injected and SEFI (Sequential Electronic Fuel Injection). These cars were a significant step forward in driveability and power/torque production compared to the CFI/carb vehicles they replaced. Trucks used a similar system that was bank-fired instead of SEFI, and used higher fuel pressure. There were only two significant issues with the early port-injected cars/trucks. First was oil consumption. Port injection allows a high flow PCV valve, so Ford went to low tension piston rings with the port-injected engines. It took a few years to get the bore/ring interface correct, and it's not uncommon for the early ones to burn a quart of oil every 1,000 miles. the second was injector clogging. It was found that fuel would hang on the injector tip after shut down and evaporate, leaving deposits on the tip of the injector. Flow would degrade over time requiring injector cleaning or replacement. Ford scrambled to update the design of the injector to move the pintle up into the body of the injector which helped, but in 1988, ethanol was approved as an additive in pump gas. Injector problems went away after that.

<to be continued>

Last edited: