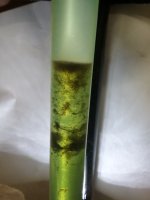

This is what ethanol fuel did to the primary jets on the Holley 390 carb in about 7 months.

I wanted to post this earlier, but, I wanted to make sure that I had the facts correct before posting.

It’s pitiful that we have to go through this.

These jets were nice and shiny when installed. If you look closely, it looks like the brass is corroded.

I never seen this happen on ethanol free fuel.

I’m stopping complete use of ethanol fuels in everything that is carbureted. This is downright ridiculous. Jets should last for years.

Just wanted to give everyone a heads up on what to expect when using ethanol fuels.

I wanted to post this earlier, but, I wanted to make sure that I had the facts correct before posting.

It’s pitiful that we have to go through this.

These jets were nice and shiny when installed. If you look closely, it looks like the brass is corroded.

I never seen this happen on ethanol free fuel.

I’m stopping complete use of ethanol fuels in everything that is carbureted. This is downright ridiculous. Jets should last for years.

Just wanted to give everyone a heads up on what to expect when using ethanol fuels.

Last edited: