How to Test Your Stock DuraSpark II Ignition System Parts With a Volt / Ohm Meter

The DuraSpark II Stock System Parts

https://www.fordmuscle.com/archives/2006/12/DuraSpark/Images/duraspark_sm.jpg

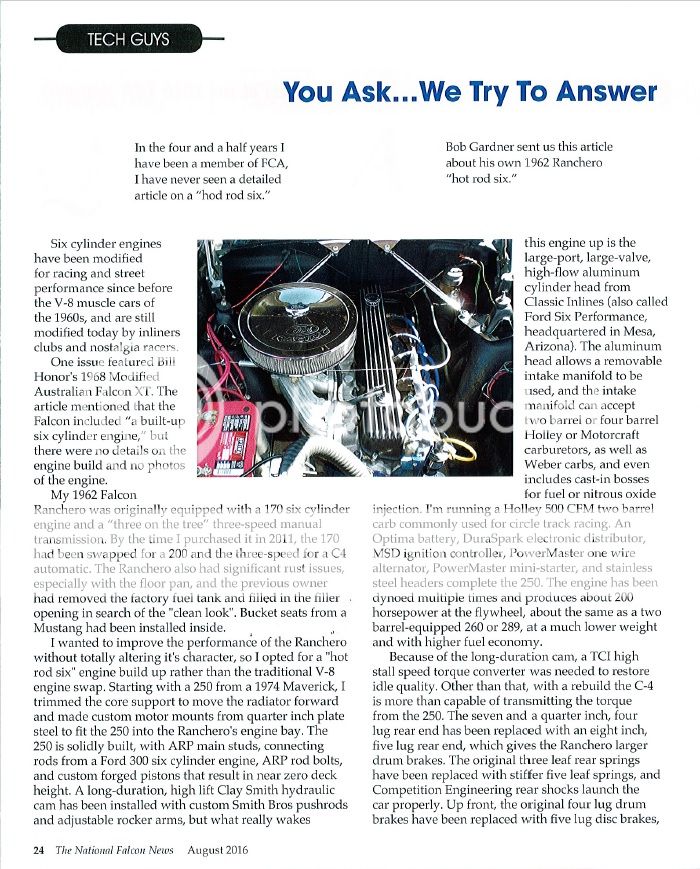

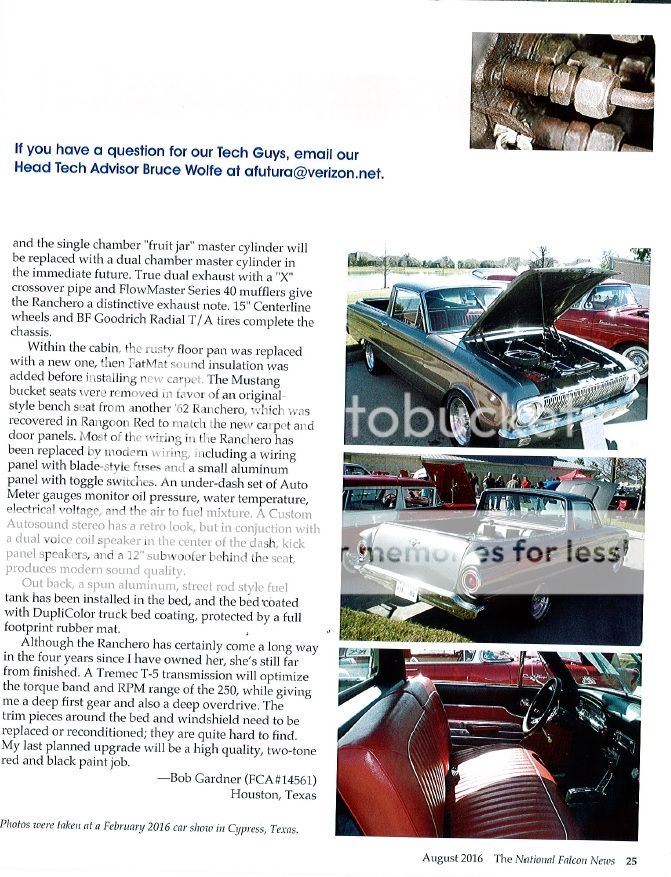

Note that the only difference in 4, 6, or V8 engine's DuraSpark II parts is mainly just the Distributor that needs to be engine specific, plus it's Cap, Rotor, and Spark Plug Wire Set. All of the other ignition system parts used are the same. I.E. The Coil and Blue Strain Relief ICM, Note that the Wire Harness is the same except that it might be a different length for an Inline Six over those used on both a 4 Cylinder or V8 engine.

1. First thing is to test is the condition of the battery and its charge, clean the battery posts and the cable terminals. The battery charge needs to be at least 12.5 volts (Write down your voltage reading result for reference) if its not at minimum voltage then try charging the battery up and retest. Now you need to do a cranking voltage test on the battery (again Write this result down for reference), if when your cranking the engine over the battery voltage drops to less than 9 volts the battery will need to be replaced. Again these are the first things to do and is very important to check out that the battery voltage is at the minimum voltage or higher, plus the battery cables condition, cleanliness of all of their connections at each end and they need to be tight before you can accurately do any other voltage reading tests.

2. The voltage to the ignition coil positive terminal should be at the same voltage reading as when your were cranking the engine over. If its not then clean any corrosion, repair or replace a damaged wire coming from the ignition switch (Usually this was a Pink Wire for many years), or if there's no damage then it’s time to replace that worn out ignition switch if you get a lower voltage reading. Next with the power switched off use your Volt / Ohm Meter to test the DS II coils primary resistance at its two terminals. Replace the ignition coil if this reading exceeds 3 ohms resistance.

3. Next with your Volt / Ohm Meter check the resistance of the distributors pickup coil with the ignition switched Off, by unplugging the distributor from its wire harness. Test the pickup coil resistance between the two parallel blades of the distributor plug, According to "Billy the Distributor Guy" (Ford Six site member wsa111) The resistance in the pickup coil should be in the 400-800 range. Most check out close to 600. if its not in that minimum range or if its way higher than you will need to replace the pick up coil. Also test the resistance between each of the two parallel blades in the distributor plug (one at a time) together with the single perpendicular blade. Replace the pickup coil if its reading is below 70,000 ohms.

4. Plug back in the distributor wire harness again, test the cranking voltage to the ICM (Ignition Control Module). Probe the White wire to read its voltage at the ICM while you are cranking the engine over. If the voltage is weak (below the cranking voltage) or there isn't any voltage at all, examine the White wire for any type looseness at terminal connections, clean any corrosion, check for any external wire damage, or internal wire breaks from the starter solenoid's S terminal and repair as needed. If the White wire checks out as in good condition then you will need to replace the starter solenoid.

5. Next Probe the Red wire at the ICM with the ignition switch in the Run position, the voltage should be the same as it is at the battery. If voltage is less then at the battery check the condition of the Red wire for looseness at terminal connections, clean any corrosion, also check for any external damage, or internal wire breaks repair as needed. Next check the Ground wire resistance by probing the Black wire at the ICM and at the

Distributor Plug. clean or repair the Black wire if a Volt / Ohm test shows more than 0.3 ohms resistance. If the trouble still continues and all other ignition system parts have checked out as good then it is time to replace the ICM.