I've read through all the starter threads I could find here on Fordsix (especially @bubba22349's excellent "Starter swaps..." thread that I've read like 5 times) and searched online till my eyes bled, but I can't find any information on a smaller case replacement available for the high-mount, 2-bolt, 4.130" registry hole, 3/8" ring gear depth starter on my '67 200 w/manual trans. Is there really nothing available?

I'd like to replace my gigantic factory starter while I have the exhaust off, but I can't find anything other than an identical gigantic replacement.

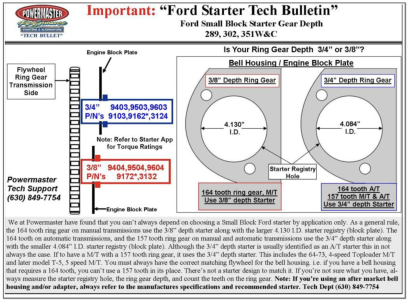

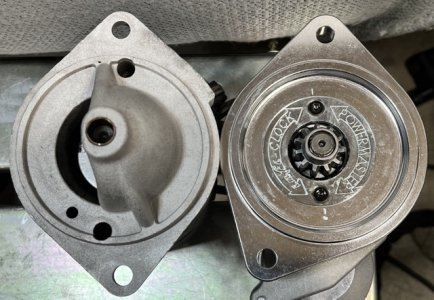

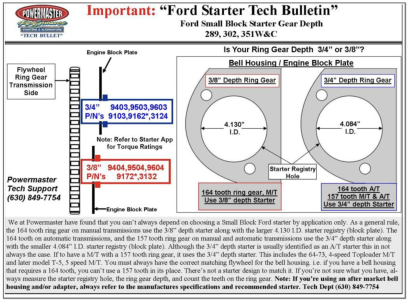

I see that there are Powermaster starters on this chart with the correct 4.130" registry hole and 3/8" ring gear depth, but they are for SBF V8's and looking at the mounting holes, they don't line up with the mounting holes on my 200 starter. The holes on the 200 unit are almost straight across from each other (maybe 175-178 degrees?) and the SBF holes look like they are 165 to 170 degrees.

Has anyone out there among all the manual trans owners actually found and used one that fits? Any information is appreciated.

I'd like to replace my gigantic factory starter while I have the exhaust off, but I can't find anything other than an identical gigantic replacement.

I see that there are Powermaster starters on this chart with the correct 4.130" registry hole and 3/8" ring gear depth, but they are for SBF V8's and looking at the mounting holes, they don't line up with the mounting holes on my 200 starter. The holes on the 200 unit are almost straight across from each other (maybe 175-178 degrees?) and the SBF holes look like they are 165 to 170 degrees.

Has anyone out there among all the manual trans owners actually found and used one that fits? Any information is appreciated.