A

Anonymous

Guest

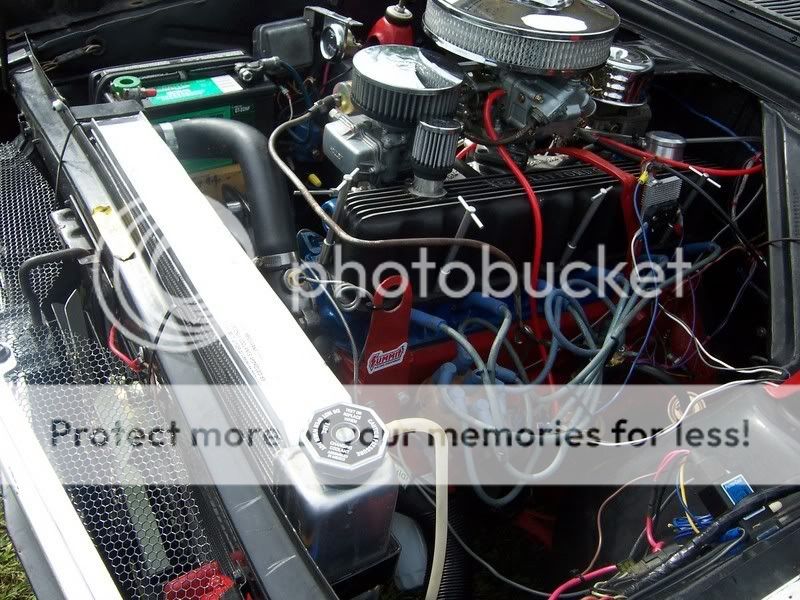

I just bought a '75 Granada with a 250, C4, and 8".

The plan is to put this combo into a '61 Comet and replace the 170 and 3 speed.

The 250 has a stuck intake valve, and the thing has a good 135,000 miles on it. I'm going to take the mill to a machine shop and have the head and the block done right. I'm thinking a mild cam (a little more than stock) and get that thing to breath a little better. (port the head intake and exhaust).

What are some recomendations on things to have done or a good set up?

This will be on a smog free vehicle.

On the front page of this site is a break down of levels on builds. I'm looking at something between a level 2 and level 3.

I want the car to be set up as a good daily driver that can keep up with traffic here in San Diego, and have the thing get up and go when the gas pedal is hit.

The plan is to put this combo into a '61 Comet and replace the 170 and 3 speed.

The 250 has a stuck intake valve, and the thing has a good 135,000 miles on it. I'm going to take the mill to a machine shop and have the head and the block done right. I'm thinking a mild cam (a little more than stock) and get that thing to breath a little better. (port the head intake and exhaust).

What are some recomendations on things to have done or a good set up?

This will be on a smog free vehicle.

On the front page of this site is a break down of levels on builds. I'm looking at something between a level 2 and level 3.

I want the car to be set up as a good daily driver that can keep up with traffic here in San Diego, and have the thing get up and go when the gas pedal is hit.