A7M, you are so right. The OHC is the only game in town if you want revs galore, but I'll put my spin on things.

For what I'm about to say, I hope its not too negative, because the OHC stands head and shoulders over the x-flow.

Firstly, this is complicated because untill you've been left high and dry with a foreign EFI engine with no parts back-up, you can't begin to realise the hassle and stress involved. Over here, they are easy to get from wreckers or aftermarket supplies or Ford, and they are so tough! Like, 221 hp and 270 lb-ft tough on the 4.0 XR-6 versions. Some stock early 3.9 TBI's were less than 170 hp, and only 228 lb-ft.

The x-flow OHV swap Jack did into his 66 Stang was a fairly cheap pick-up as foreign engine swaps go, but he spent lots getting everything sorted, and had JD and help from all the way (and possibly you A7M).

It's not fair to for any of us lucky Aussies or Kiwis to say that an OHC engine is an easy swap into an

American Ford. I've been intimately involved with electronics since 2000, and all I can say is they are a crock of endless stress unless you know the ins and outs. If you follow the factory systems from a late model Falcon and put it in a Mustang, bank on a total need of about 5 US grand (assuming 1500 delievered, service assistance and wiring help to run the stock EEC Falcon wiring loom, or buying an aftermarket ECM) and three months from the time its landed. I'M NOT KIDDING!!!!. The OHC is also longer than a US 250, so you have to look at getting the right serpentine drive and radiator parts sorted.

My friend Richard got his EFI X-flow and wacked it into his Cortina for a fraction of the cost.

Everything new has no parts support from Ford US. The stock gearbox, fuel lines, ECM, belts, and all the ignition bits are foreign.

Since the customer calls the shots on what he wants, the person providing the components must ensure that the customer ends up with the best compromise between performance and service.

Spyke said:-

I assume those OHC motors are fuel injected? I want a real simple setup ( ie. carby ). But if they are better then the xflow and the ignition and fuel injection is not too complex may be worth looking at.

The OHC is a great, strong engine if you have the later 4.0 liter engine. The earlier 3.9 OHC wasn't that flash. All OHC engines are injected.

Engine mounts...just use 200 US three bolt mounts. Most ohc's have the same block pattern, but after 1998, they got a huge alloy sump and other mods which make fitting them tricky. Ones after 1995 had no distributor, but it returned in 1996-1997.

The OHC

wont take a C4 unless you convert to the SBF adaptor I use. The six has the starter nesting where the cam was in the old ohv I6's, and needs the US SBF starter fit a V8 C4 behind it.

The stock SBF C4 will then fit. A stock American 200 C4 wont fit without a lot of work, and the V8 C4/C5's are more common anyway.

Stock OHC T5's are avaliable with the OHC, but they have a different clutch and flywheel to the US stuff. Jack uses the stock Aussie bellhousing, and then a standard T5.

Most OHC's have BTR LE 65 fully electronic 4-stage autos, or early ones have the Borg Warner 55 3-stage. The BTR interfaces with the TPS and igniton, so its not easy to fit a C4 unless you use the T5 manual electronic EFI, and fit a vehicle speed sensor.

Most people look at Supra 5-speed manual gear boxes and the Castelmane Rod Shop adaptor from CRS.

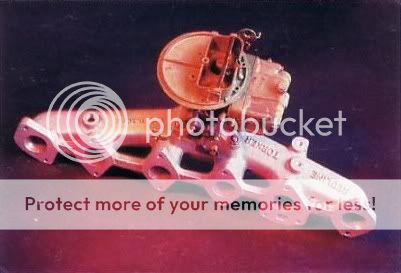

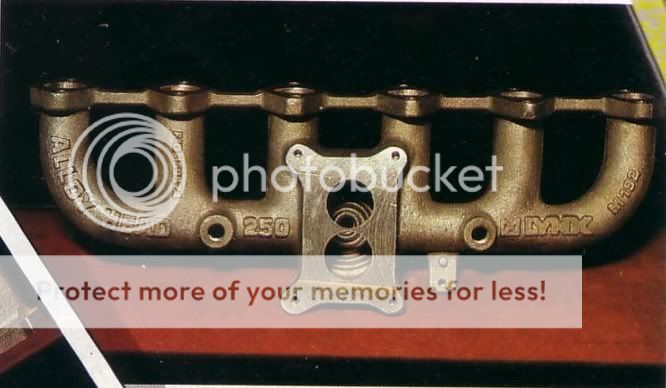

Lastly, if you want

no electronics, the best option is to take a later 1992-1994 4.0, adorn it with the 1988-1991 OHC 3.9 TBI intake, and bolt on an 1987-1993 x-FLOW 250 Weber ADM 34 carb. You use the Aussie XE distrubutor, and may have to devise an electric fuel pump. There is the option.

Basically, you take all the later electronic gear, and throw it in the trash, and use this intake manifold. It runs fairly close to the shock tower, but should be okay.

As for websites, there are many. Please go through

George's posts on his X-flow Cortina in the Aussie Forum, and look at the links he had.