No worries mate, I get it now!

Before I start, I'll say that if you are contemplating a non independent runner system, then use the non independent runner formulae from this link.

http://fordsix.com/forum/viewtopic.php?p=50275&highlight=#50275

Meantime, please work through each example. I guess that example 5 sums it up best.

All 2-bbls are rated at 3"Hg

Most 4-bbls are rated at 1.5"Hg

Example 1:

The 2-bbl Weber 32/36DGAS and Holley Weber 5200 are 227 cfm at 1.5"Hg.

To convert between a standard pressure drop to another kind, just take the standard pressure, divide by the new one, take the square root, and you get a factor.

If 227 cfm at 1.5"Hg is to be conveted to 3"Hg, then 3.0/1.5=2, and root 2 of 2 is 1.414.

Take 227 cfm, multiply by 1.414 to get 321 cfm.

Same with Holley 350 and 500 2-bbls. They are rated at 3"Hg, but are 247 and 354 cfm at 1.5"Hg.

Example 2:

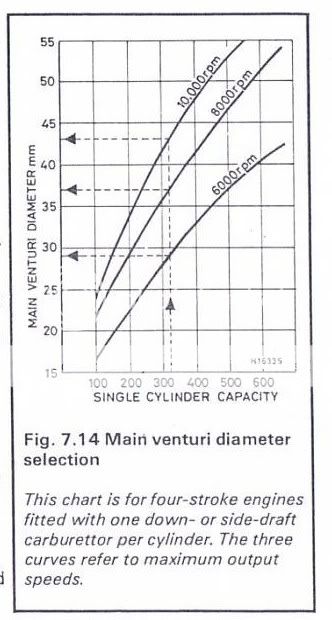

Now, lets say we have one 514 cubic inch independent runner tunnel rammed ProStreeter running to 9000 rpm. By Holleys formualae, with 105% volumetric efficiency, you'd need a single 1405 cfm carb. In fact, people use two Holley Dominator 1150 cfm at 1.5"Hg carbs, or four cut-up 1150 cfm carbs. As soon as you run independent runner systems, the volumetric efficiency goes up, and the peak vaccum goes down, way down. On a 514, each cylinder has 1052 ccs to suck, and from the chart above, it needs eight 2.0" or bigger venturis in a savagely bored out Dominator carb. The peak flow is off the scale at 1.5"Hg would be about 1400 cfm per each carb.

Example 3:

One Weber 48IDA with 42 mm venturis flows 296 cfm per barrel at 1.5"Hg. Three of them flow 1776 cfm. A GT40 289 had four, and flowed 2300 cfm or so at 1.5"Hg.

Example 4:

As you add carbs, you improve volumetric efficency. A stock 4-bbl carb in a V8 will gain about 5% VE if an independent runner carb system is added, and up to 25% power if the cam is optimised to suit the venturi diameter for a specfic rev range. It's nothing to get 10 to 25% more power out of downdraft IDA or IDF Webers, and they exceed the best power of an efi or Hilbourn type system because they pulse tune fuel. Maserati, Aston Martin, Ferrari and Lamborghini have done it for years. 375 hp from a 2 vave per cylinder head from 3.9 liters, and a specific torque of about 1.2 lb-ft per cubic inch of engine, which is very impressive. The record is about 1.4 lb-ft per cube, I think.

Example 5:

On your six, going from one venturi to to six veturis improves volumetric efficiency by about 20%. The flow efficiency from the stock 1-bbl to the outer No1 and 6 cylinders is very, very bad because of the sharp bends. It's rare for any single barrel American origin log type manifold from AMC, Kaiser, Hudson, Ford or GM to have a flow handicap of less than15% on the outer cylinders. The air/fuel ratio which gives 12:1 for cylinders 3 and 4 gives 13.5 to 14:1 for the outer cylinders. If you have more carbs, you have less bends. If you go to 6 carbs, the VE can in theory go up to as good as an engine with no manifold. In most cases, and intake manifold is a 10 to 25% flow handicap to an internal combustuion engine.

On the Log head, six venturis is the best single alteration as there is a flow distribution problem with one carb feeding six cylinders.

If you run three 1-bbl carbs, the set-up is worse than an indepednent runner/port on port system, but a massive improvement on the stock 1-bbl system. This is why the Offy style intakes get great results for little cash outlay.

The ideal carb CFM at 3.0" Hg for three carbs on a 200 engine running to 5000 rpm?

Well, the engine will have an 85% VE rather than 75% when you do the cam to suit. The head flows better with three points of distribution verses one. Total air flow is

200*5000

3456*0.85

= 340cfm. This is spread over three carbs.

There is a now a calculation you can use to find peak flow at wide open throttle.

Take the planned ventri area of the three barrels. Say there is three 38 mm, or 1.496".

This is an area of pi* R squared, or 3.141*(1.496/2)*(1.496/2), or 1.757 square inches each. In square inches, that's 5.27 squares total. In sqaure feet, that's 0.03662 sqaures.

Then, take 340 cfm, and find how fast in feet per second the air speed is. At 1.5"hg, air speed is about 275 feet per second, or 16500 feet per minute. In a 3.0" Hg carb, it is 390 feet per second, or 23400 feet per minute.

With three 38 mm carbs feeding a demand of 340 cfm, the peak speed is V= Q/A. 340 divided by 0.03662 is only 9285 feet per minute. This is a factor of 1.77 less than the rate of 1.5"Hg, so the actual pressure at wide open throttle is 0.84"Hg.

I would say any carb with a 38 mm bore should flow 201 cfm at 1.5"Hg, and 284 cfm at 3.0"Hg. Either of those carbs should work out okay.

In the case of non independent runner systems, the rule I use is 70 to 34 cubes of engine for every square inch of carby area. With a 200 running three 38 mm carbs, it has 37 cubic inches or engine for each sqaure inch of carb.