Keeping the terms of reference to just a non turbo engines for a moment

Re-read

FrenchTown Flyers advice on what was observed during the Brand F**d small block 5.0 engine program. CFI has a very poor fuel atomisation, or 'roosters tail', while the 4180 Holley is one of the champions. Yes, CFI or TBI work well enough on a non turbo, and can yield good power with two injectors. Yes, 120 to 140hp form a smog 302 is okay. Same for 205 hp from a 1982 and 84 Corvette 350 Crossfire, or 180 hp from a 305 or whatever from a TBI 350, or the 140 or so from the 3.8 Taurus yada yadayada. But guess what? They used single plan, open chamber plenumbs on equidistant engines with a cylinder a stones throw away.

Not a labyrinth of bends and curves.

Even the best US D8 I6 and on heads were a little 'bendy' in the port approaches.

Changing the terms of reference of this discssion to include turbos, then you just need to append the evidence.

Realio trulio little red dragon Turbo 200's like drag-200stang's beast, or even a milder 250 I6 like Does 10s, and certainly the radically boosted 1-bbl 200 Foxstang like Linc 200's, have the same things poping up. One carb doing a high pressure mix of fuel to six cylinders. If its carburetor, it may just work without detonation issues in the 12 psi area. If you add a TBI or CFI unit, it will form a more poorly atomised fuel distribution, it will be more likely to detonate with a single TBI or CFI injector.

If either of these three gentlemen had used pee and drible single CFI set-up, then there engines would be scrap right now!

Even if you richen up the fuel delivery by increasing pump pressure, injector size, or whatever, you won't improve tha atomisation charateristics because a venturi does a better job than EFI in atomising fuel.

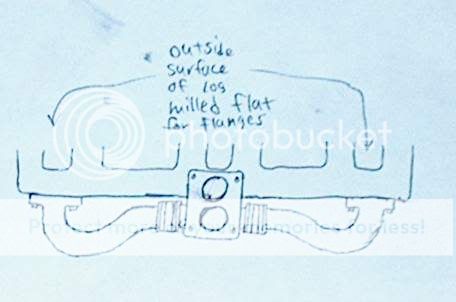

To do a Turbo 200 justice, you'd need to run the sort of system

drag200stang is looking at now (hint hint!), or a triad of CFI thottle body EFI units, like this.

If you were to use carbs, such as the Holley 2300 series (or 2150 or 2100 series 2bbl Autolite or Motorcraft, or 3 38 DGAS Webers), then you've got to have have something like this in a high boost situation

.

Or at the very least, two CFI units or two 2-bbl carbs like

Mustang Geezers.

I guess anyone who has destruction tested there 200 (Linc200, drag200stang) have sort an American Idiot Red Heart,

and they automatically should be benchmarks we should listen to. Rather than being idiots, you guys are wise beyond your years!If your not blowing up engines, your not learning anything!

As for why 500 hp 3 liter and 3.3 litre turbo engines are a real force in Aussie racing, its simple. Most of them are cheaper and easier to get, and when you blow one up, you just get another block form the junkyard, and start again. In Aussie, the Ford guys have to use 4.1 (250) cube engines to beat Datsun 3.0 and Holden 3.3 turbos, but only because there Ford Falcons are 6 inches wider in the track and wheelbase, and a lot heavier than equivalent Nissan Skylines and Holden Commodores.

Enjoy yourself fellows!