You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford 200 Custom Crank position for Terminator x

- Thread starter Jmustang_65

- Start date

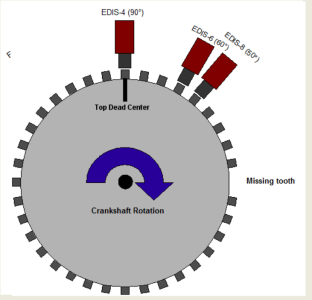

No you want it at the 7th before. The ECU need 60 degrees to get it right, the missing tooth should be clockwise of the sensor at TDC.. Holley has some good instructions for the 36-1 on their site.

If the key shown is keyed to the crank ,it does not look like you are at TDC, check that. Can you explain how the damper works with this setup?

If the key shown is keyed to the crank ,it does not look like you are at TDC, check that. Can you explain how the damper works with this setup?

Last edited:

Jmustang_65

Famous Member

Isn't the 7th before digital raising?

The damper is bolted using the 3 bolts.

I'm using an htd belt setup.

The damper is bolted using the 3 bolts.

I'm using an htd belt setup.

No, it does not work that way. digital raising is when the hall effect sensor first sees the tooth the signal is raising up and when it passes the tooth the signal falls.

It counts the first tooth after the missing tooth not the 7th, you set it there because the ecu need 60 degrees to work. The 7th tooth is 60 degrees.

Engine turns clockwise, the way you have it it will fire 120 degrees after TDC.

It counts the first tooth after the missing tooth not the 7th, you set it there because the ecu need 60 degrees to work. The 7th tooth is 60 degrees.

Engine turns clockwise, the way you have it it will fire 120 degrees after TDC.

Bronctopia

Well-known member

Exactly right.No, it does not work that way. digital raising is when the hall effect sensor first sees the tooth the signal is raising

To put a little bit of detail to it.... The Hall sensor sends a signal for each tooth edge to the ECU. What the ECU does is start a count as soon as it receives that signal, and stops it when it receives the next "rising edge".

The count value let's the ECU know how long it takes a tooth pair to pass, which let's it figure out the RPM.

Initially it does not know "where" in engine cycle it is, until that missing tooth passes (and another 'normal' gap as well).

It can't begin firing until it has both the angular speed AND the missing tooth timing marker.

This situation is kinda like a drummer in a band. He will start first, and everyone else will listen to pick up the tempo and time before playing.

The ECU calls this "Sync".

In a band it is "the Beat".

Jmustang_65

Famous Member

I need to study this more. Thanks for the info. Still not understanding it. lol

Just keep at it, keep thinking and reading, if it was easy everyone would do it.

I have a dominator setup not running yet and I know the it supports the 36-1, I assume that the Terminator X does too, but I cannot find that it does, so you know that it does right?

If you search ''holley 36-1 tooth crank trigger system for a big block chevy'' you can get instruction with pics.

If you search ''holley 36-1 tooth crank trigger system for a big block chevy'' you can get instruction with pics.

Jmustang_65

Famous Member

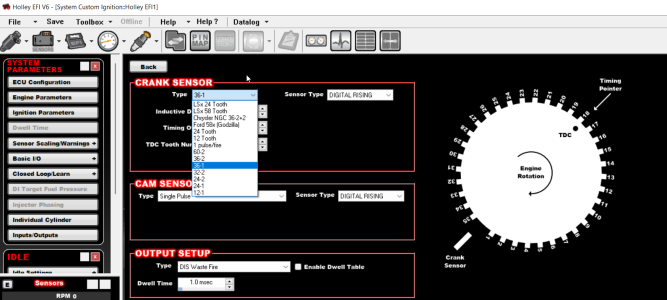

Yes, its in the dropdown.I have a dominator setup not running yet and I know the it supports the 36-1, I assume that the Terminator X does too, but I cannot find that it does, so you know that it does right?

If you search ''holley 36-1 tooth crank trigger system for a big block chevy'' you can get instruction with pics.

Jmustang_65

Famous Member

Jmustang_65

Famous Member

Current screenshot of available crank sensor options.I have a dominator setup not running yet and I know the it supports the 36-1, I assume that the Terminator X does too, but I cannot find that it does, so you know that it does right?

If you search ''holley 36-1 tooth crank trigger system for a big block chevy'' you can get instruction with pics.

I found this picture which helped understand on were to add the sensor to the 60 degree mark.

View attachment 25384 That will help but all efi systems are not the same, you need to be at the 7th tooth for 60 degrees for holley not 6th as shown. I would like you to search the web for ''holley 36-1 tooth trigger wheel system for a big block chevy'' you may have to scroll down to get past the sell you stuff but it is there. I would post it up but the forum will not let me or post pics. The technical drawing is holley 199r10835.pdf

Last edited:

Bronctopia

Well-known member

From the Crank sensor screenshot he posted, it looks as if he may have the option of specifying how many teeth from the gap/sensor TDC is at.

Can't really tell, because the drop down is covering the field.

That would be convenient flexibility for locating sensors, and the tooth count between gap and TDC is really just an integer variable in the code. It may be hard coded for Stock wheels and sensors, but assignable for custom.

Can't really tell, because the drop down is covering the field.

That would be convenient flexibility for locating sensors, and the tooth count between gap and TDC is really just an integer variable in the code. It may be hard coded for Stock wheels and sensors, but assignable for custom.

That may be true, right now he is at tooth 29. it may be all good, not sure. All I know for sure is the Holley instructions for their 36-1 wheel say to set it at the 7th tooth before (which would be counter clockwise) of the missing tooth at top dead center.From the Crank sensor screenshot he posted, it looks as if he may have the option of specifying how many teeth from the gap/sensor TDC is at.

Can't really tell, because the drop down is covering the field.

That would be convenient flexibility for locating sensors, and the tooth count between gap and TDC is really just an integer variable in the code. It may be hard coded for Stock wheels and sensors, but assignable for custom.

Last edited:

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 3

- Views

- 19K

- Replies

- 19

- Views

- 13K

- Replies

- 7

- Views

- 13K